Error control processing method for CD drive track-finding servo

A technology of error control and processing method, applied in the direction of optical recording/reproduction, head configuration/installation, data recording, etc., which can solve the problems of reading failure, slow data reading, poor design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

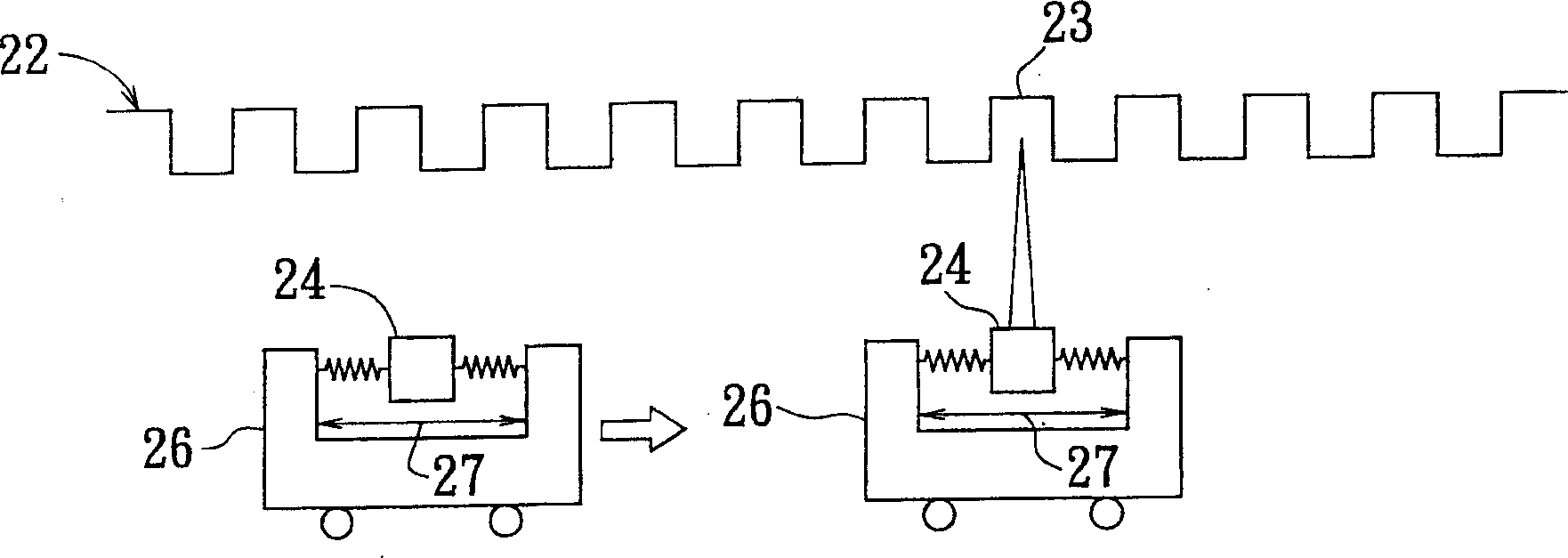

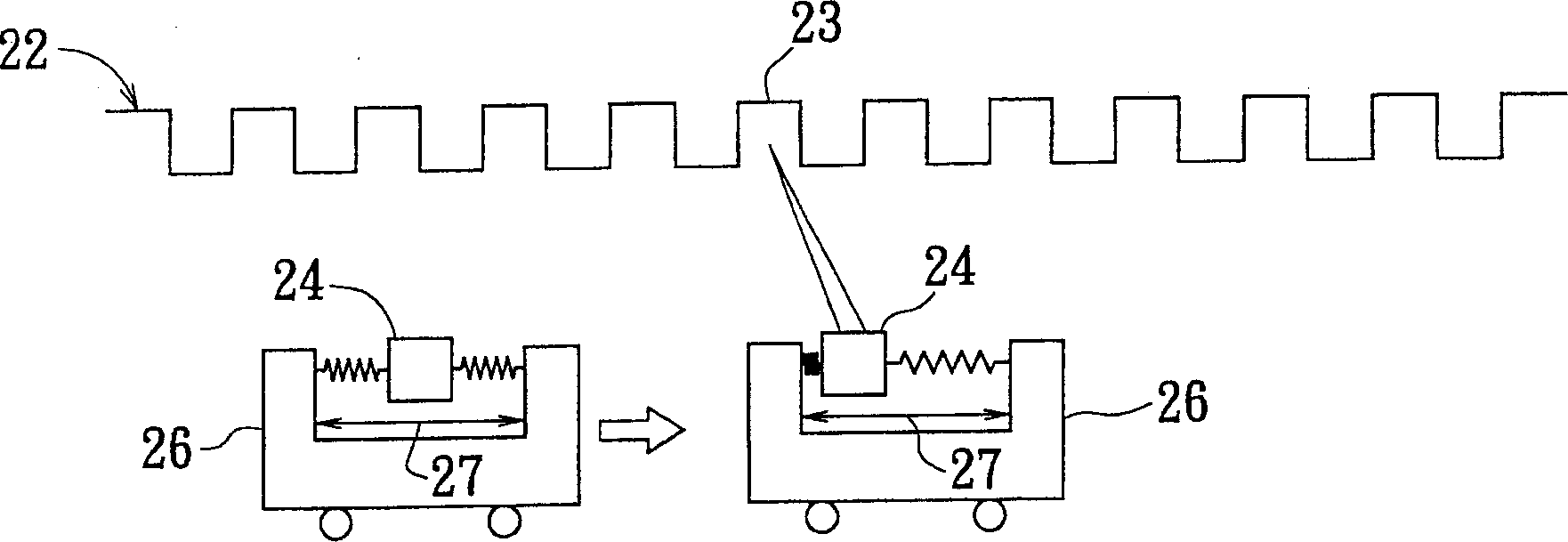

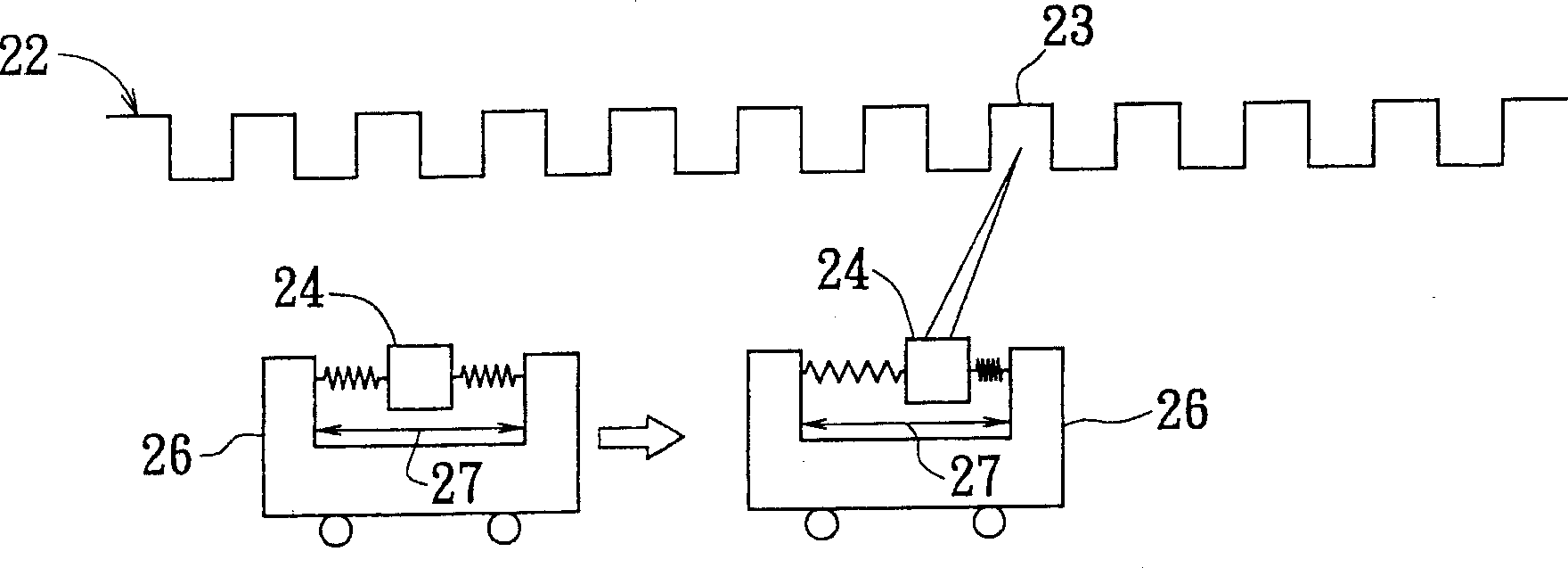

[0023] The present invention is an improvement aimed at the fact that when the track-locking action of the known optical head fails, the track-tracking servo system will take quite a long time to try to perform the track-locking action of the optical head, or there is no way to complete the track-locking action at all. The present invention starts to calculate a track-locking time when the track-locking action of the optical head starts. Generally speaking, the rail-locking action of the optical head takes a very short time, and the rail-locking action of the optical head can be completed within a few microseconds (us). When the rail locking time exceeds an expected time, it can be determined that the rail locking action fails, and according to the embodiment of the present invention, the expected time is 3 milliseconds (ms). Therefore, when the track-locking time exceeds 3 milliseconds, according to the embodiment of the present invention, the track-locking action must be aba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com