Setting method and setting apparatus for operation path for articulated robot

A multi-joint, robotic technology, applied in the direction of instruments, manipulators, simulators, etc., can solve problems such as long-term cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

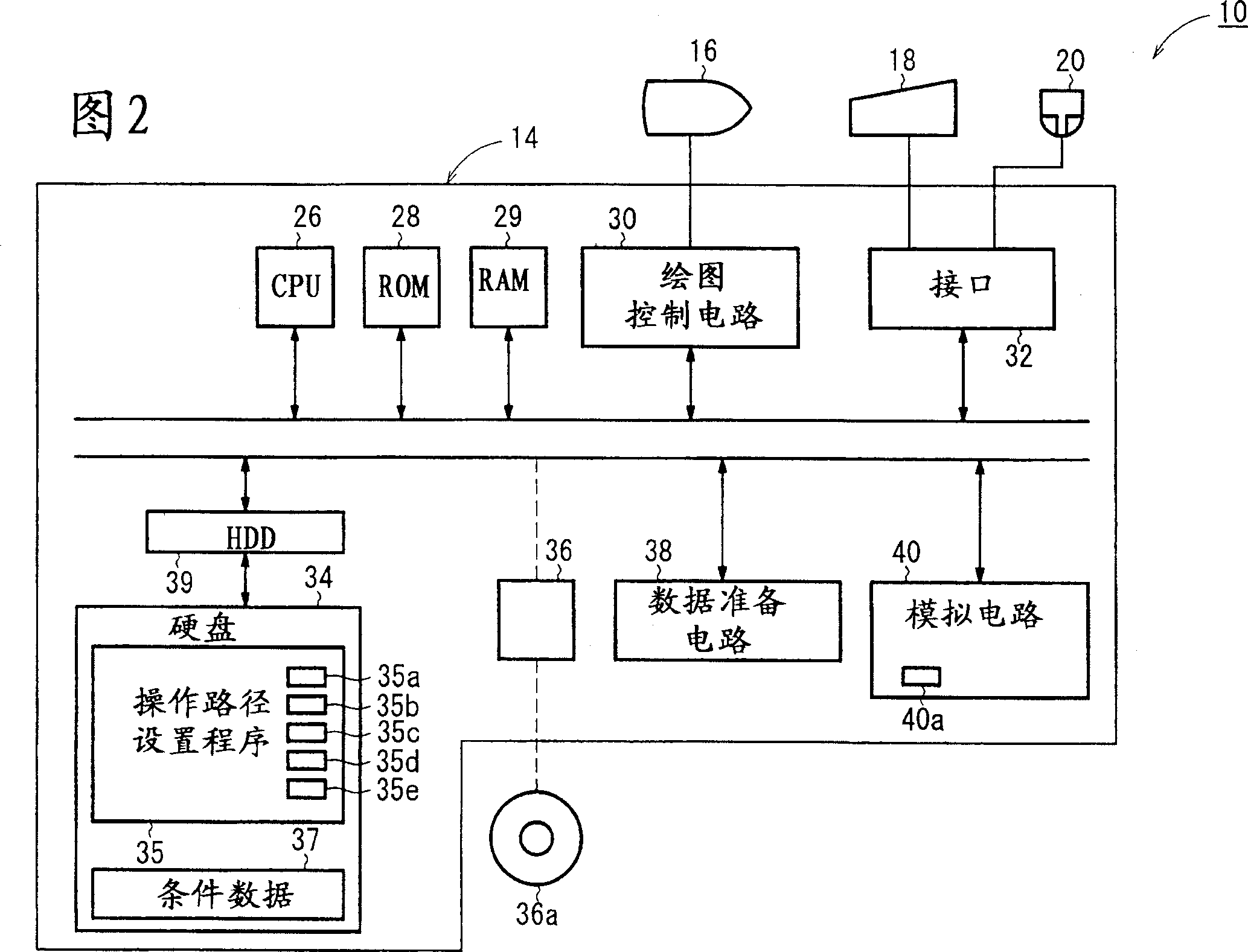

[0066] The following will refer to Figure 1-21 An illustrative embodiment of the setting method and setting apparatus for the operation path of the articulated robot of the present invention will be explained.

[0067] Basically, in the setting method and setting device for the operation path of the articulated robot according to this embodiment of the present invention, when extracting a workpiece in which there is a workpiece, the end effector provided on the front end of the articulated robot is moved from During the narrow operation where the operation point on the workpiece is retracted, the operation path is set when investigating the disturbed part in the internal space surrounded by the welding torch device. During a wide-area operation for moving between retracted positions, an operation path is set to move to an arrival point while avoiding obstacles by operating when combined with a template operation that moves a specified distance from a starting point in a speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com