Electric motor coil drying equipment

A dryer and motor technology, applied in the manufacture of motor generators, electric components, electrical components, etc., can solve the problems of slow drying speed and low efficiency, and achieve the effect of simple structure, high efficiency and uniform drying of the invention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

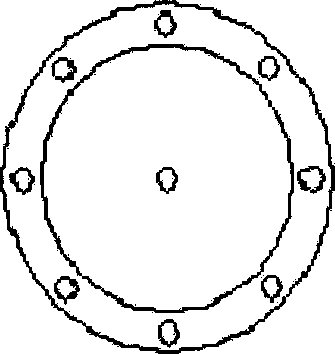

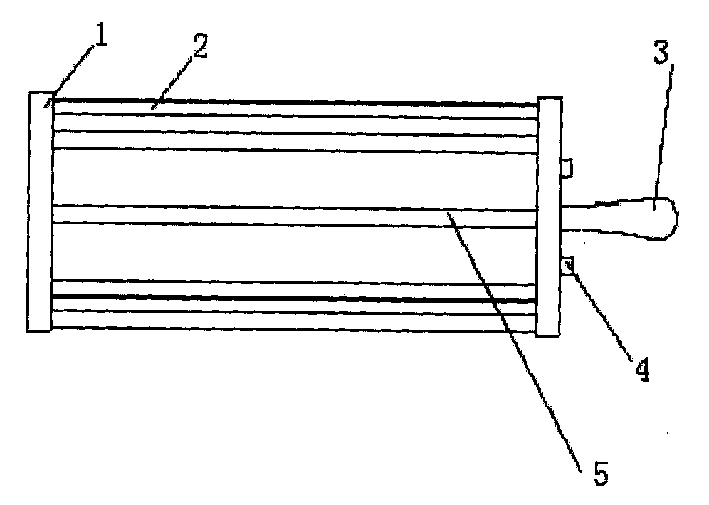

[0012] See attached figure 1 And attached figure 2 As shown, the present invention consists of a bracket 1, an infrared lamp 2, a handle 3 and a terminal post 4. At least one infrared light tube 2 is arranged on the brackets 1 at both ends, a handle 3 is arranged on the bracket at one end, which is convenient to use, a power supply terminal 4 is arranged on the bracket at one end of the handle, and a conduit 5 is arranged in the center of the bracket, and the conduit 5 At the same time, it plays the role of protecting the power cord and connecting the brackets at both ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com