Self-winding timepiece having train wheel setting apparatus

A self-winding and chronograph technology, applied to self-winding, mechanically driven clocks, spring ratchet mechanisms, etc., can solve problems such as difficulty in arranging gear train setting devices and thinning of the movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

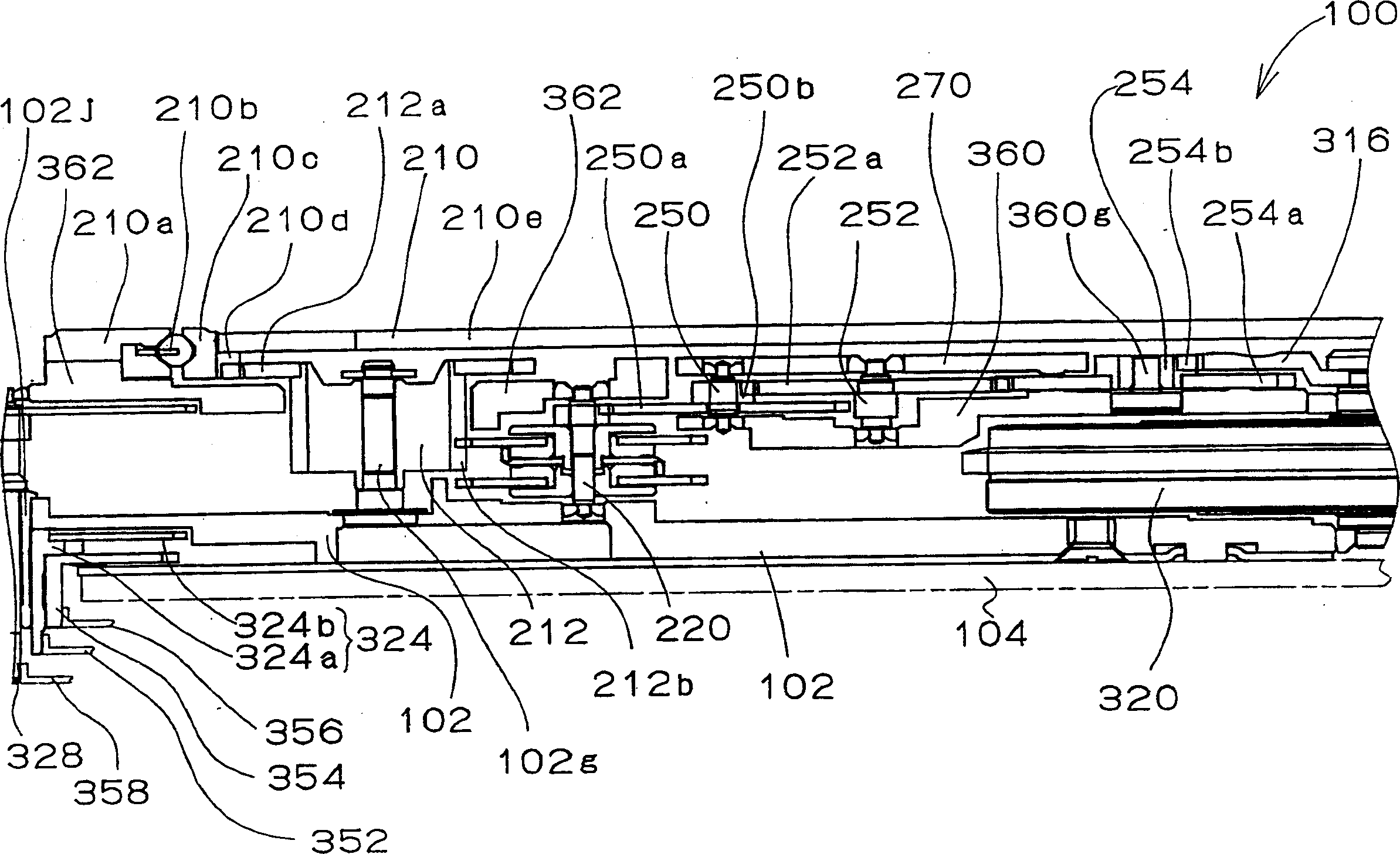

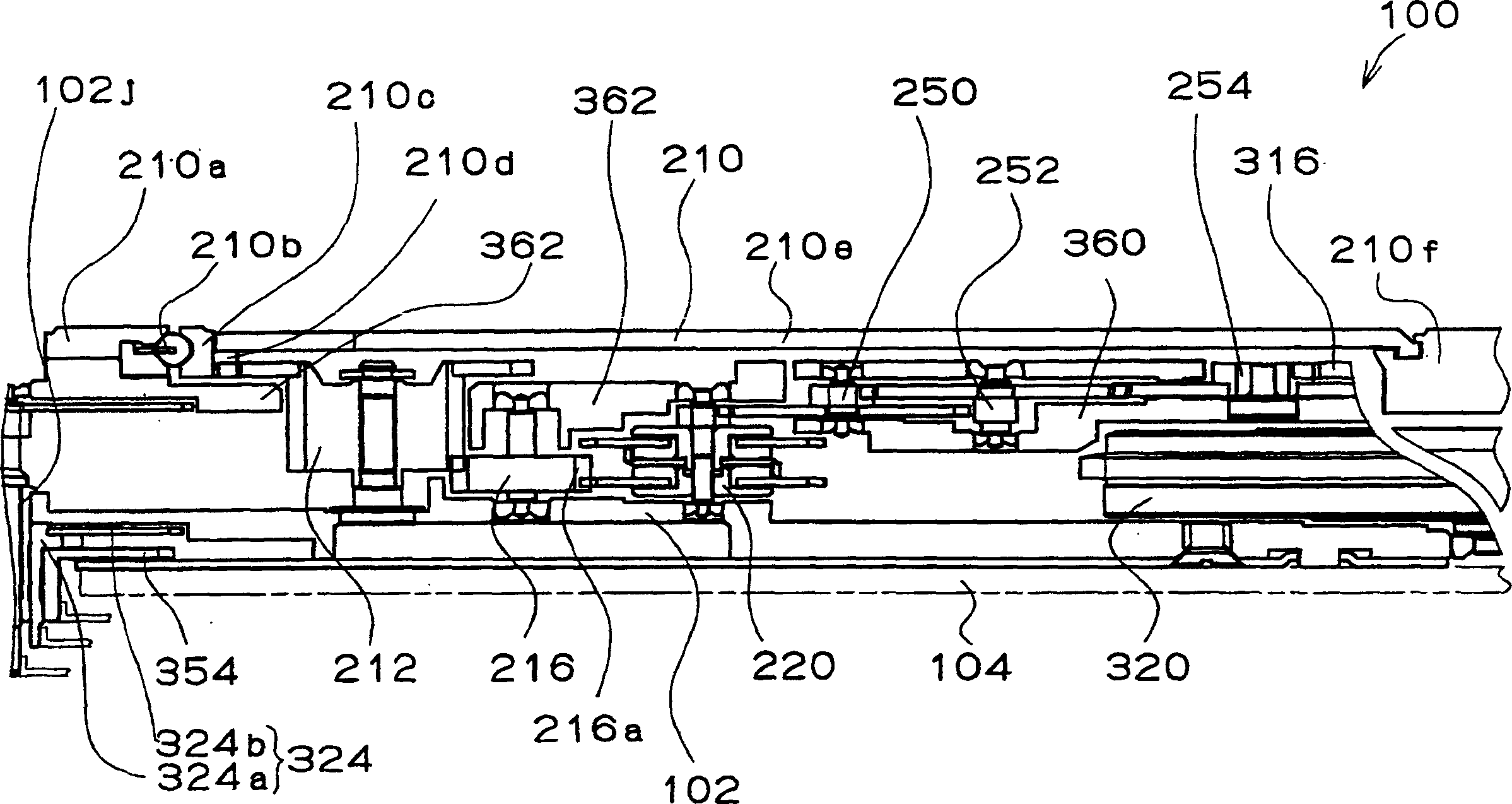

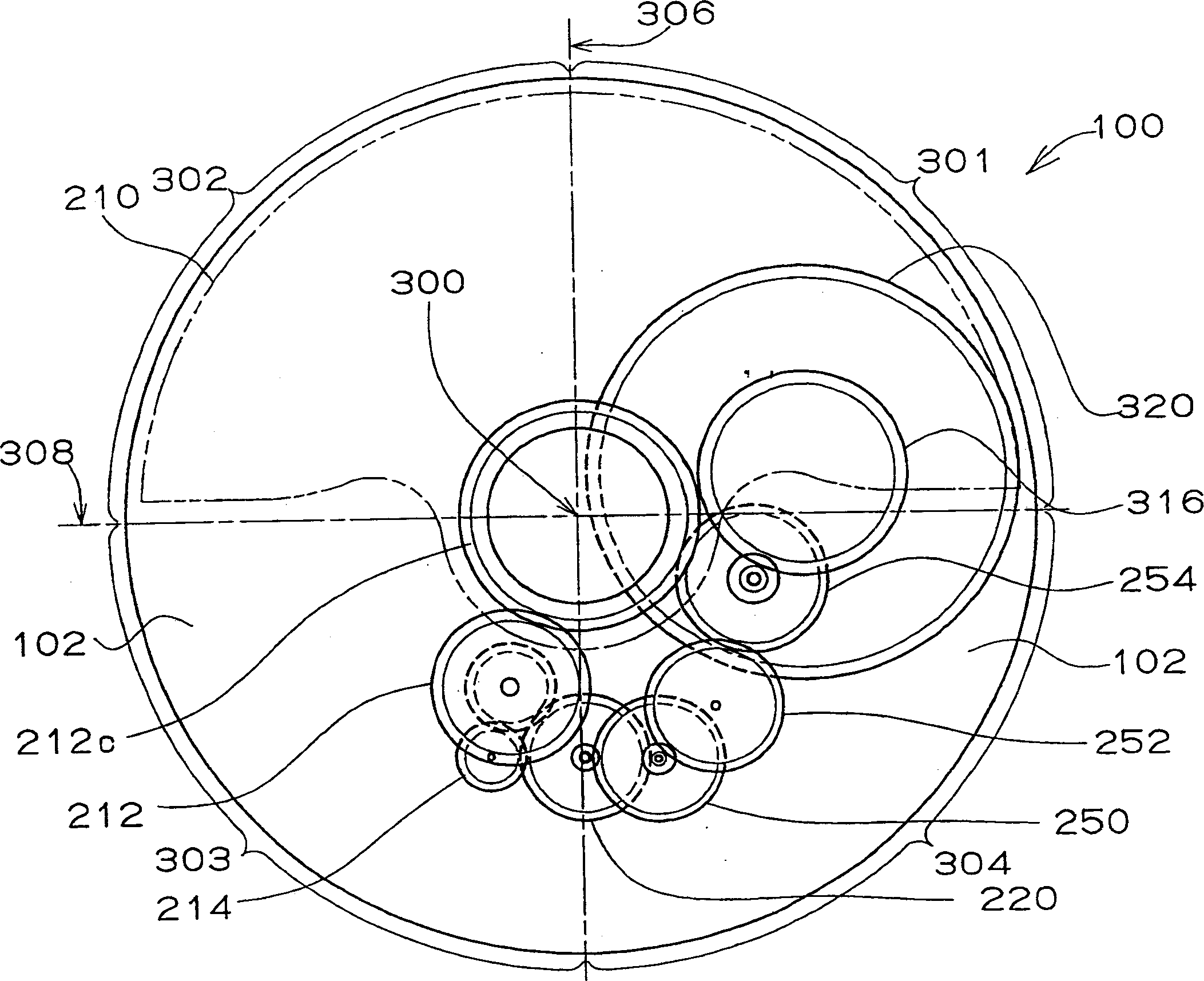

[0037] Embodiments of the self-winding timepiece of the present invention will be described below with reference to the drawings.

[0038] (1) The structure of the top side of the movement:

[0039]First, a description will be given of the structure of the top train, escapement and speed control mechanism arranged on the "movement" top side (main plate side opposite to the dial) in the self-winding timepiece of the present invention. "Movement" means the mechanical body of a timepiece, which includes the mechanisms that drive the timepiece.

[0040] refer to Figure 1~3 and Figure 7-9 , in the self-winding timepiece of the present invention, the movement 100 includes a main splint 102 , and the main splint 102 includes the bottom plate of the movement 100 . The winding stem 310 is rotatably coupled in the winding stem guide hole of the main plate 102 . Dial 104 ( figure 1 , 2 , 8 and 9 represented by phantom lines) are connected on the movement 100.

[0041] Usually on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com