Mechanism height adjustable hinge mold assembly

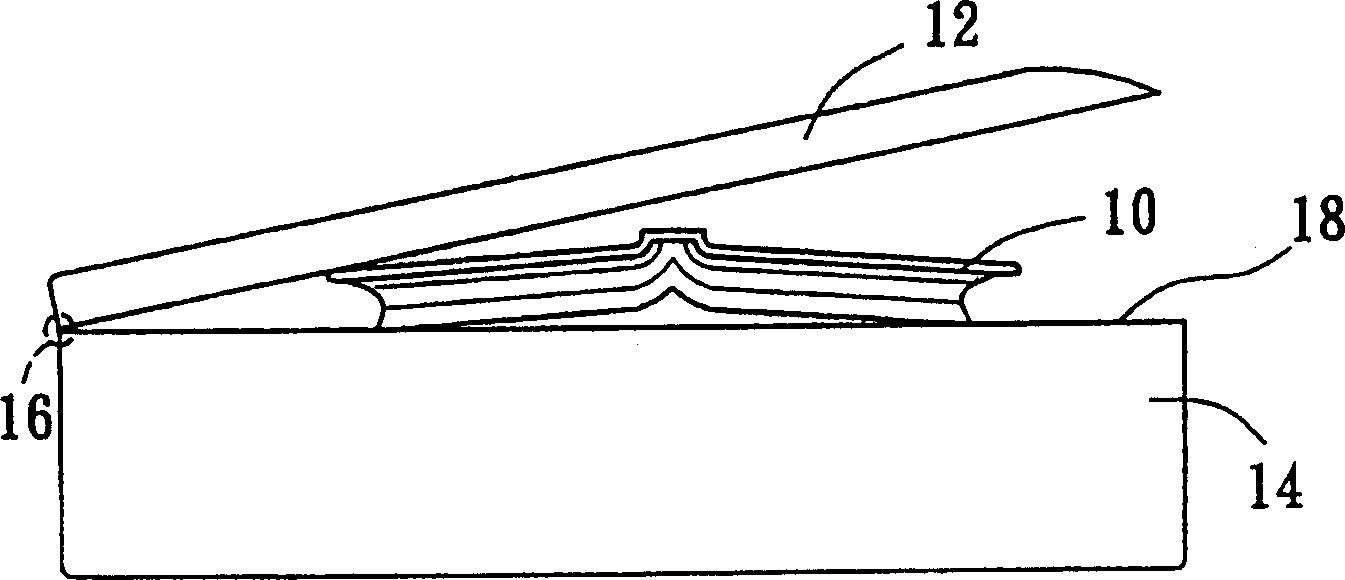

A mold assembly and hinge technology, which is applied to hinges without pins, door/window fittings, building structures, etc., can solve problems such as uneven contact points, increased scanner manufacturing costs, and unsuitable flip cover 12.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

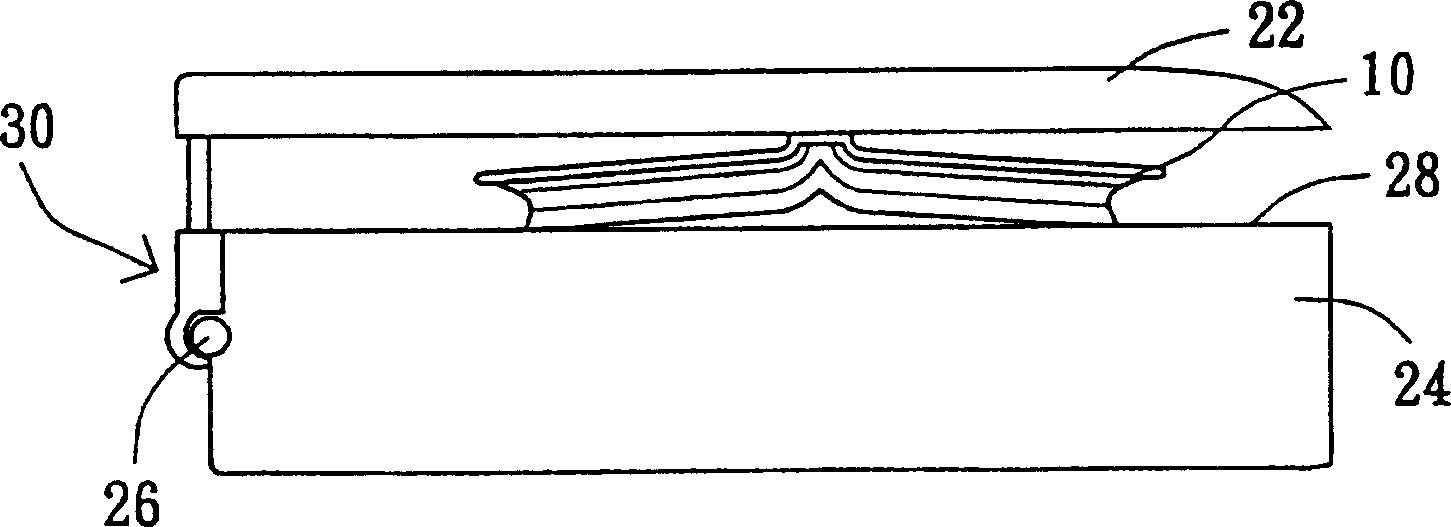

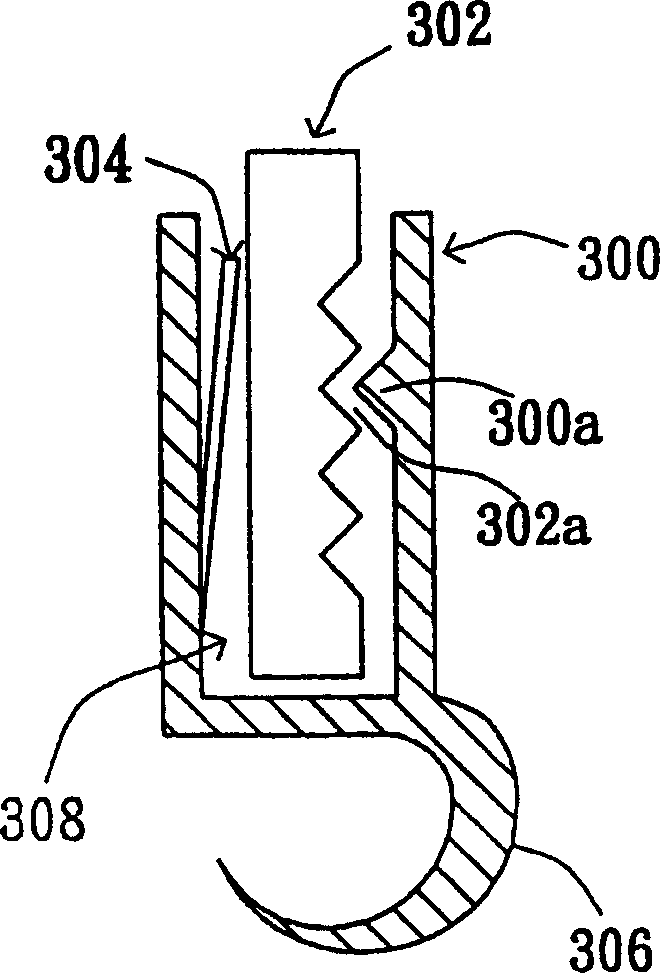

[0012] Please refer to figure 2 , Which shows a schematic diagram of using a scanner with a hinge mold assembly according to a preferred embodiment of the present invention. The hinge die assembly is a mechanism part used to combine the mechanism body and its secondary components and adjust the relative position of the mechanism body and its secondary components. The organization may be a multiple function peripheral (Multiple Function Peripheral), such as a scanner, a photocopier, and a fax machine. Such as figure 2 As shown, the mechanism takes a scanner as an example. The secondary element is the flip cover 22. The hinge die assembly 30 is sleeved on the rotating shaft 26 on the scanner body 24, so that the flip cover 22 is combined with the scanner body 24, and The height of the flip cover 22 relative to the scanner body 24 can be adjusted. When the scanned document 10 has a considerable thickness, the hinge die assembly 30 can be positioned in a stretched mode, and the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com