Assigned torsion nut

A nut, a prescribed technology, applied in the direction of nuts, screws, bolts, etc., can solve problems such as disengagement of joint parts, leakage of high-pressure fluid, major accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

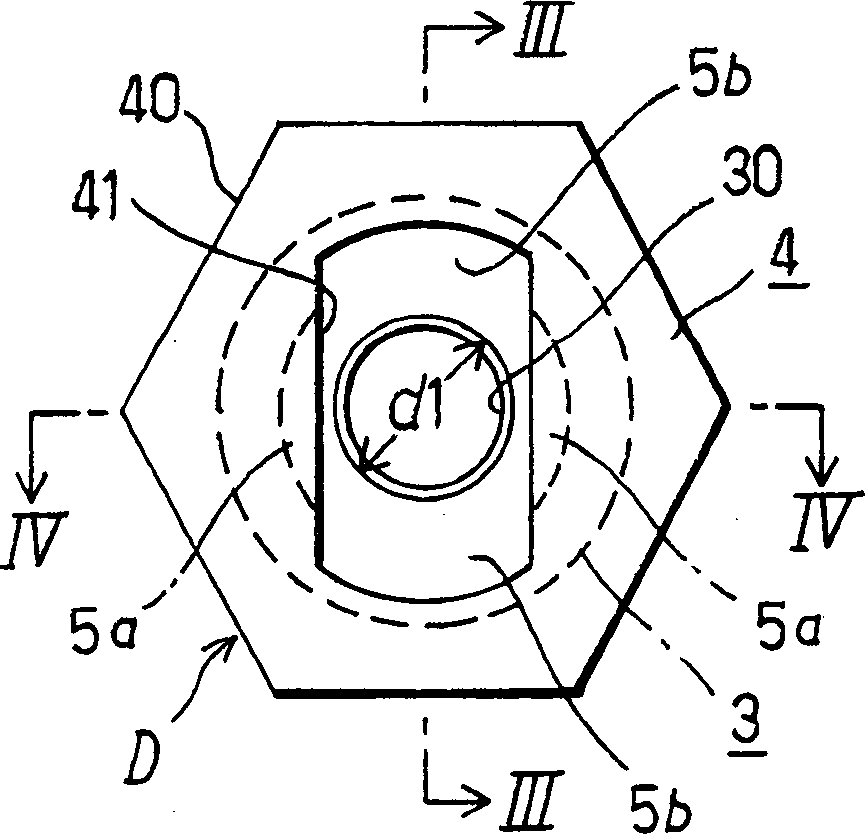

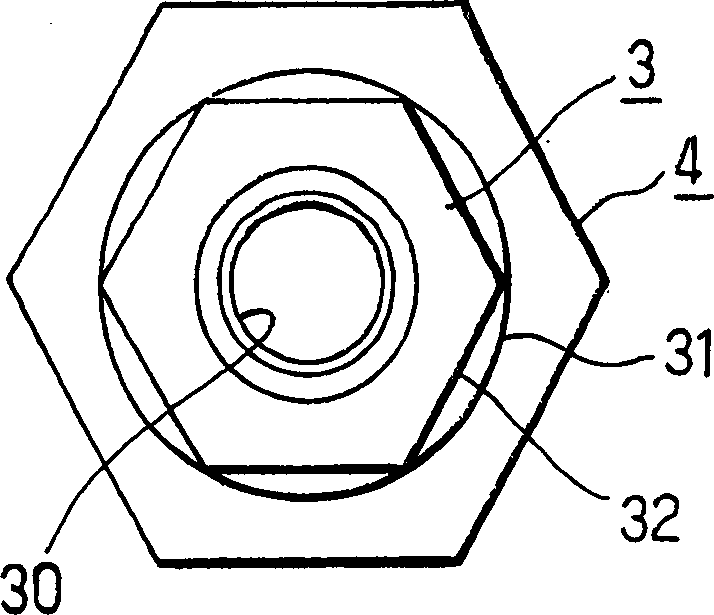

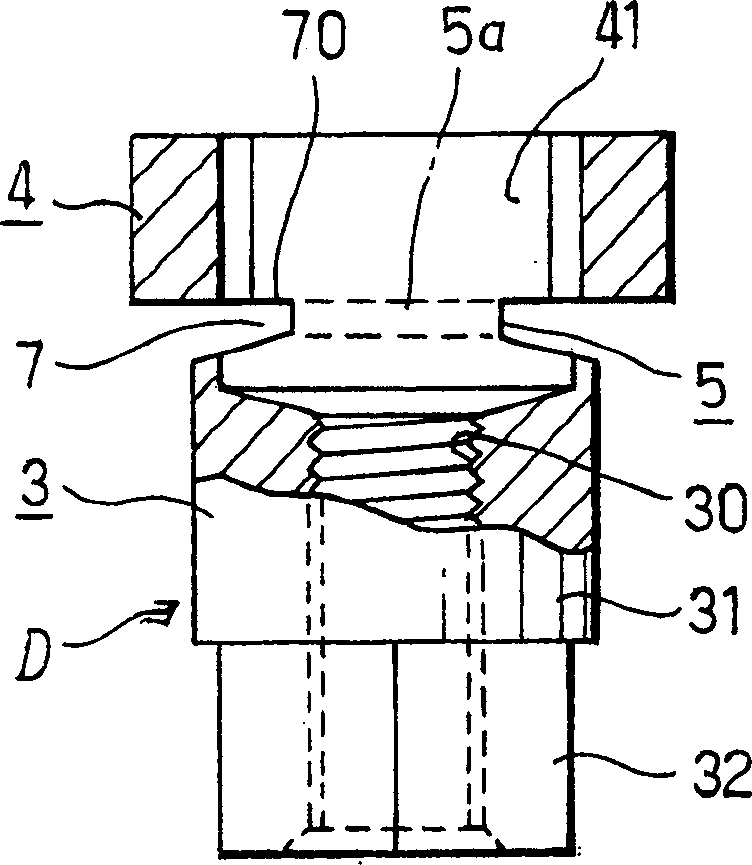

[0047] Embodiments of the present invention are described according to the accompanying drawings, figure 1 ~ Fig. 6 shows the first kind of form, and the whole of the specified torque nut of the present invention is represented by symbol D. The nut main body 3 and the torque operating portion 4 of the prescribed torque nut D are integrally connected by a prescribed torque portion (broken portion) 5 .

[0048] The nut main body 3 has a female screw hole 30 at a desired length from the lower end, and a cylindrical portion 31 and a polygonal tool locking portion 32 are provided on the outer surface. Since the tool locking portion 32 is used when the nut needs to be removed later or is reused as a normal nut, it may not be provided depending on circumstances.

[0049] In this example, the torque operating portion 4 has a larger outer diameter than the nut body 3 , and has a polygonal tool locking portion 40 on the outer periphery for applying torque.

[0050] The torque operatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com