Structure and making method of flexible circuit board for ink-jet printing head

A flexible circuit board and manufacturing method technology, applied in the direction of printed circuit components, printing, etc., can solve the problems of unstable assembly quality, easy damage, damaged conductive lines or open circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

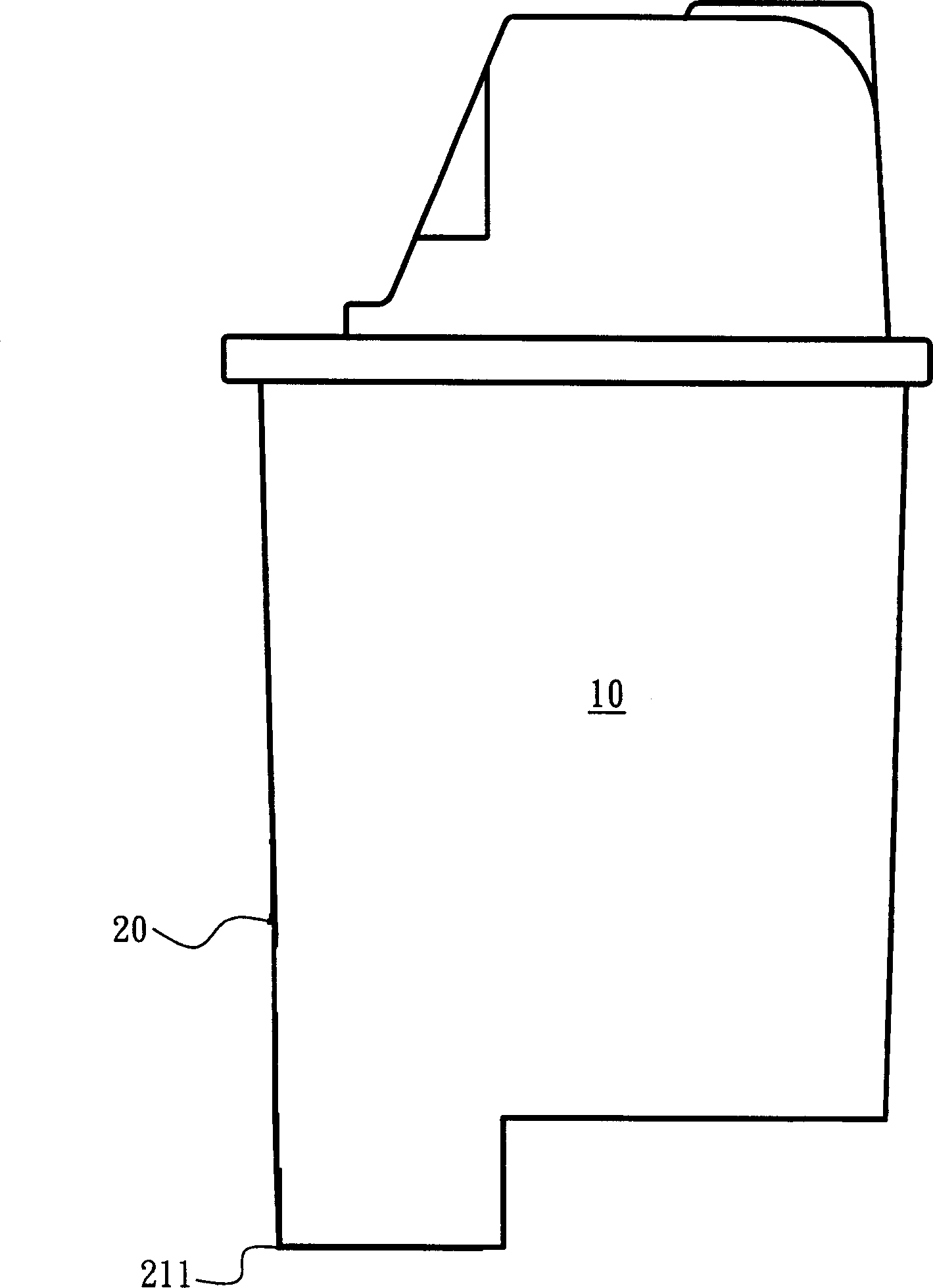

[0018] exist figure 1 Among them, the flexible circuit board 20 of the inkjet print head 10 has a bend 211 with a large angle. In the assembly process, if a known structure is used as the flexible circuit board 20, it is not easy to use the molding step to make it flat on the inkjet cartridge. alignment.

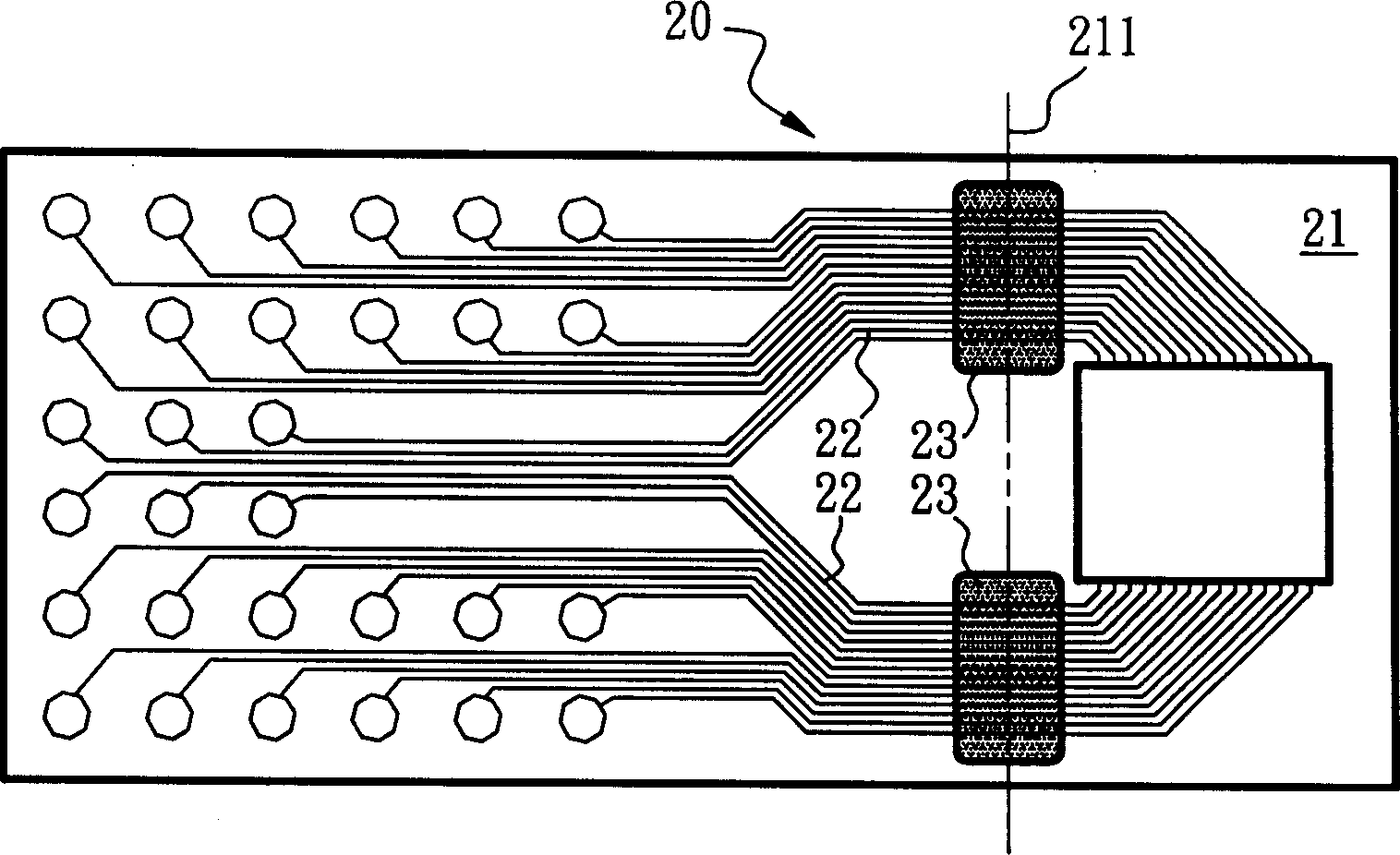

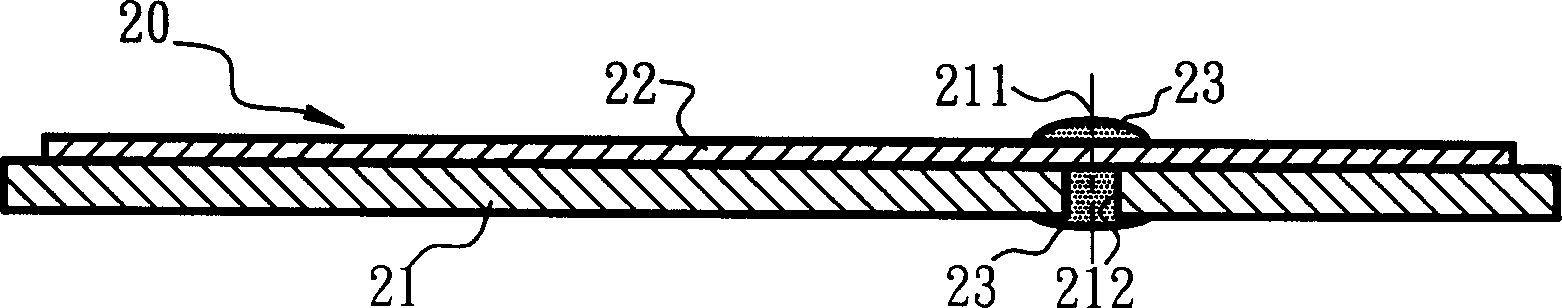

[0019] According to the embodiment of the present invention, it can be done as figure 2 or image 3 The shown flexible circuit board 20; which includes a substrate 21, a metal conductive circuit 22 and a cover layer 23; The surface of the groove crosses the slot 212 , and then a cover layer 23 is added to cover the metal conductive circuit 22 in and around the slot 212 .

[0020] One of the best implementation methods of the present invention:

[0021] As mentioned above: it includes a substrate 21 , a metal conducting circuit 22 and a cover layer 23 ; and an adhesive layer is further included between the metal conducting circuit 22 and the substrate 21 . The substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com