Method for inserting images on printing plates

An imaging and printing plate technology, applied in the field of printing plate imaging, can solve the problem of difficult silicone resin layer processing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment Construction

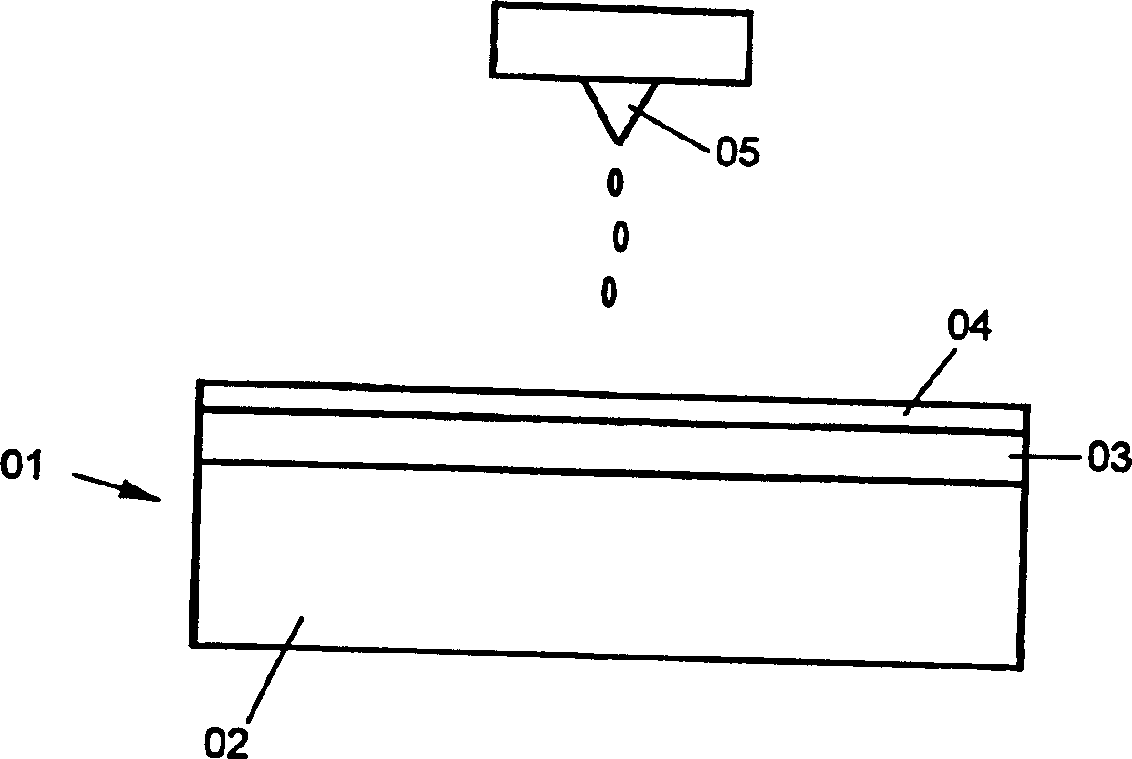

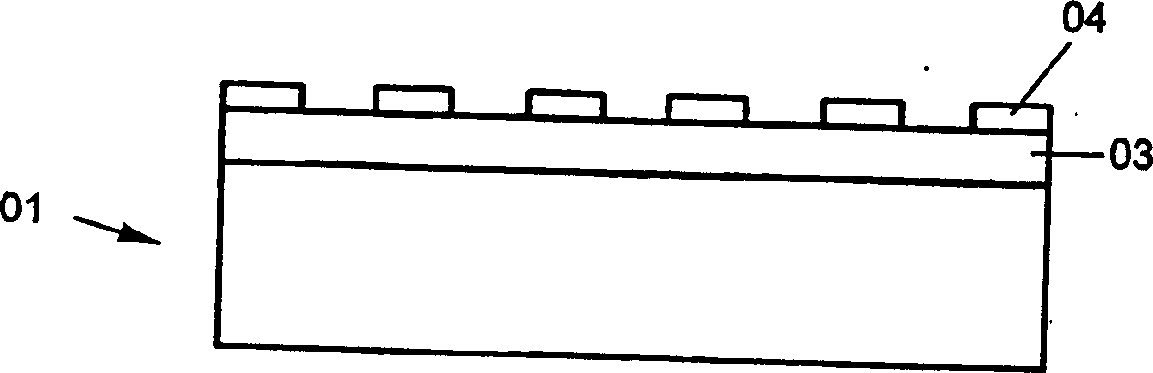

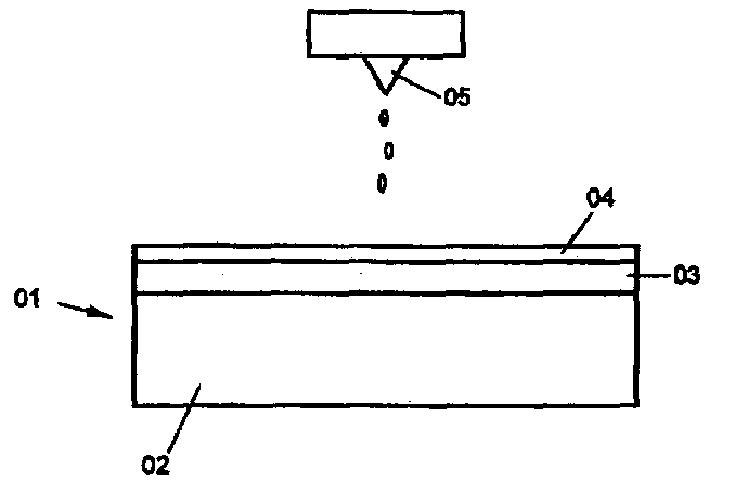

[0019] figure 1 The printing plate 01 shown has a carrier layer or matrix 02, which is composed of aluminum and has a corresponding thickness in order to achieve the desired properties. An ink layer 03 and an ink repellent layer 04 are coated on the substrate. The ink layer 03 may be a polyethylene film. Its thickness is in the range of 5-50 μm, preferably 20 μm. The ink repellent layer 04 is made of silicone resin. The thickness can be selected accordingly. Its thickness can be in the range of several μm. In this embodiment, it is 2 μm. There can be an adhesive-or bottom layer between the substrate 02 and the ink layer 03. In this embodiment, this layer is a titanium oxide layer.

[0020] Preferably, a watermarkless version produced by Presstek (trade name: PearlDry) is used, and the structure of the printing plate is clearly disclosed in US 54 87 338A.

[0021] In order to realize the dissolution and removal of the silicone resin layer in the corresponding segment of the image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com