Two-washing-tube double-power laundry machine

A washing bucket and dual-power technology, which is applied in the field of washing machines, can solve the problems that underwear and outerwear cannot be realized, and achieve the effects of enhanced friction, convenient removal, and improved washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

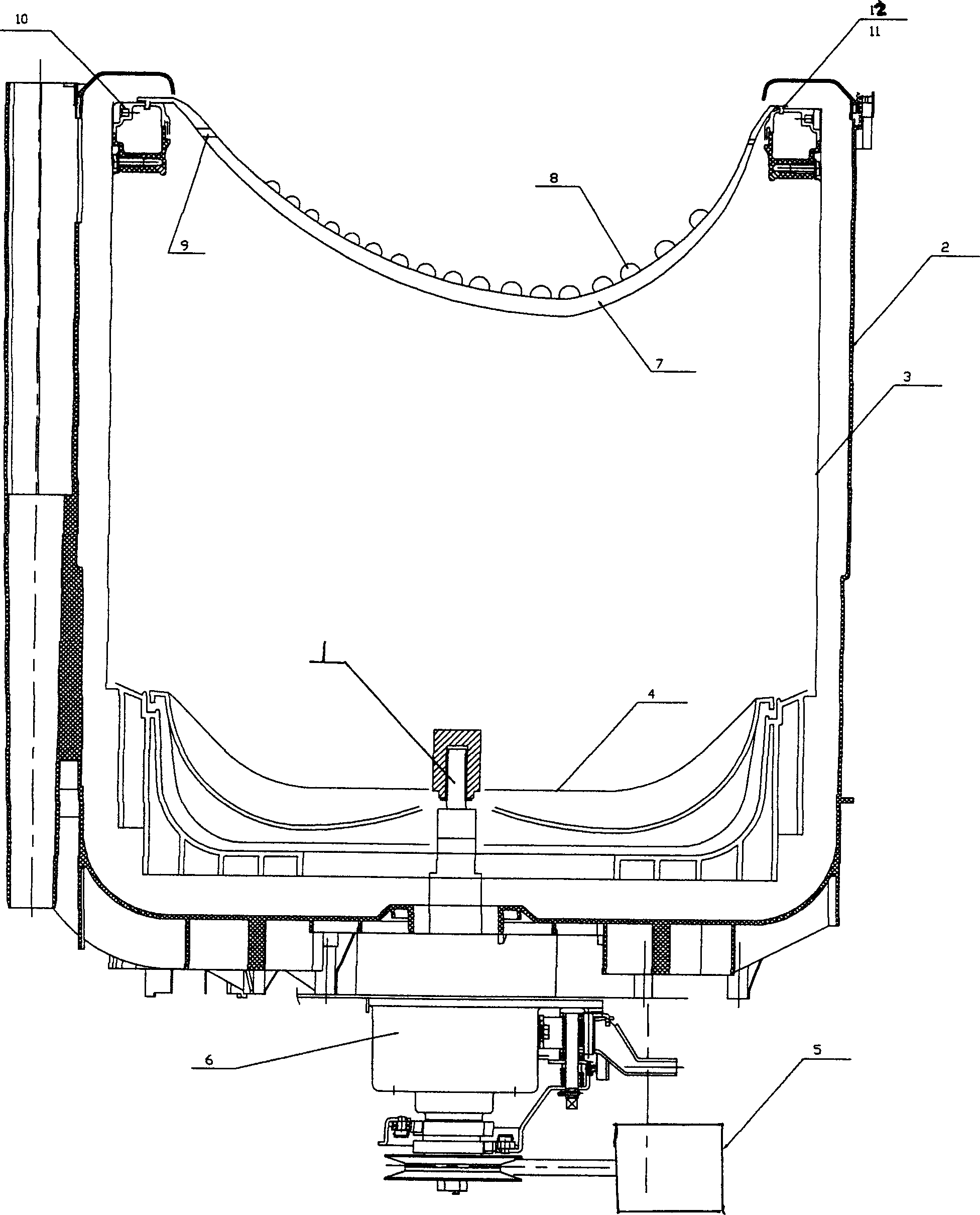

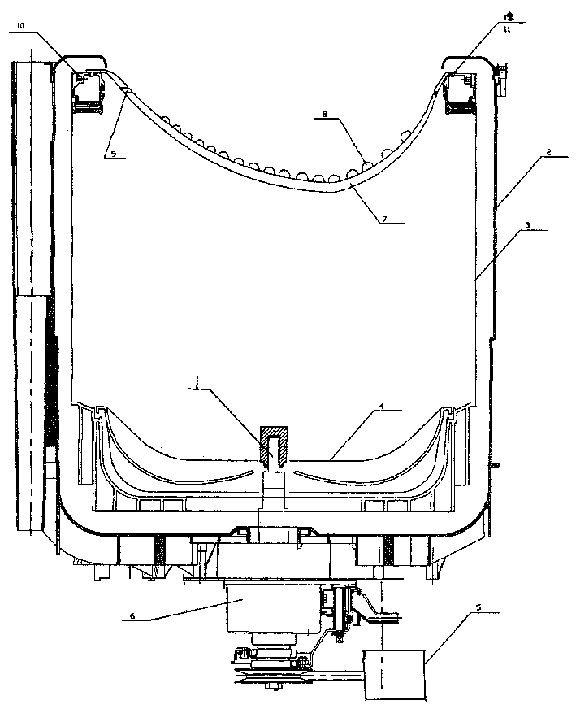

[0017] see figure 1 , embodiment: when washing, a small washing bucket 7 is added on the barrel mouth of the washing bucket 3 of the existing dual-power washing machine, and the small washing bucket 7 is provided with four claws 11 in one circle, and the balance ring 10 is provided with Four corresponding claw grooves 12 make the claws 11 be inserted in the claw grooves 12, so that the small washing bucket 7 is fixed. In order to improve the cleaning ratio, several spherical protrusions 8 are arranged in the barrel, and friction can be generated between the clothing and the protrusions 8 to wash the stains on the clothes, which has the effect of "rubbing clothes". In order to make the clothes shake back and forth during washing, the small washing tub 7 is made eccentrically, and the eccentricity is 0.28R, and R is the radius of the small washing tub 7. In order to realize automatic dehydration, several dehydration holes 9 are arranged on the upper circumference of the small w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com