Cutting equipment for brush

A technology for cutting equipment and shrubs, which is applied in the direction of cutting equipment, cutters, cutting tools, etc., and can solve problems such as time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

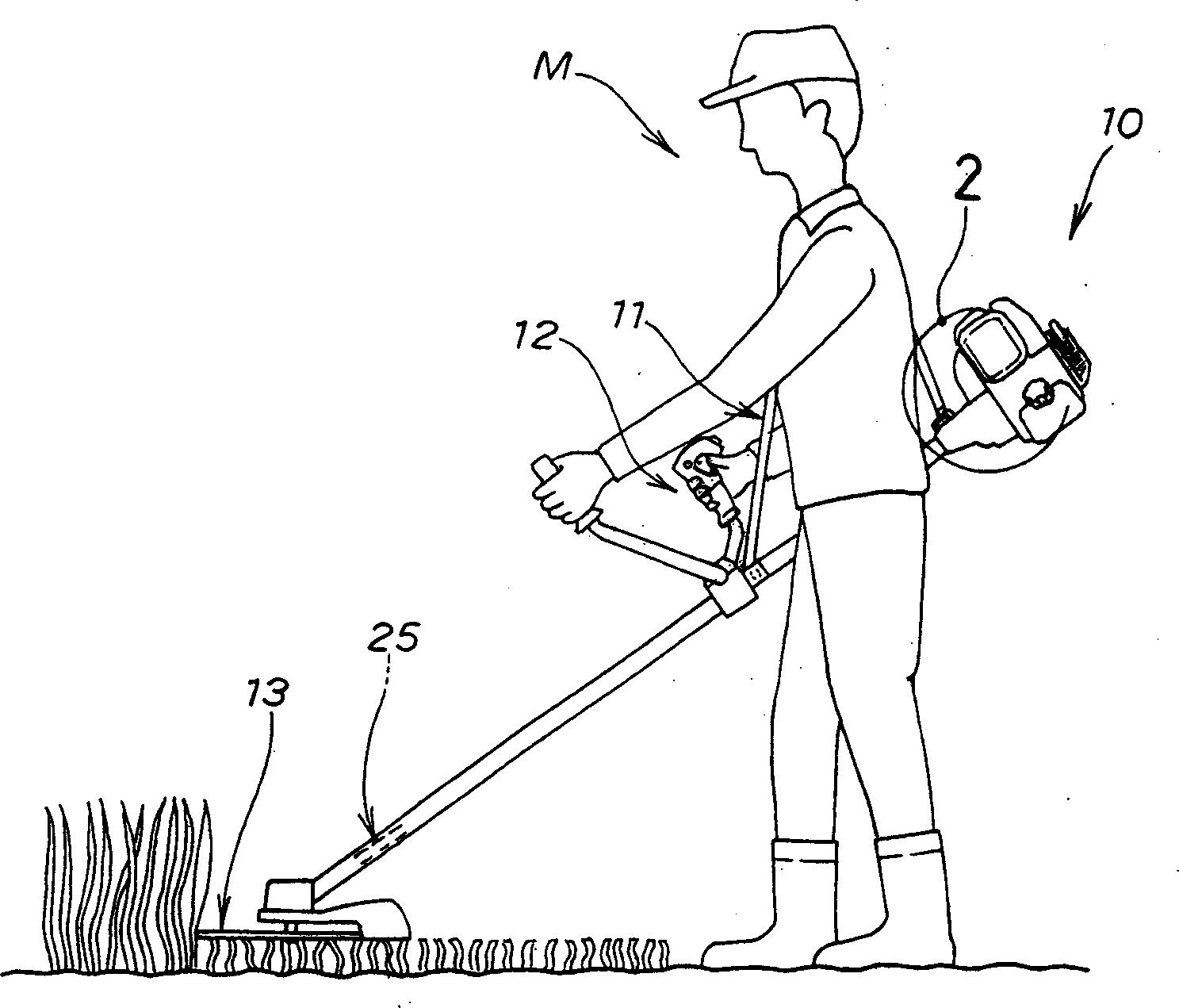

[0023] figure 1 It is a view showing the manner in which an operator cuts a bush using the bush cutting device according to the first embodiment of the present invention. That is, the operator shown here carries the bush cutting device 10 with a strap 11 suspended from one shoulder of the operator, and grasps the manipulating portion 12 of the cutting device 10 with one of his or her hands. The bush cutting device 10 includes a rotary cutting blade 13 and various other components which will be described in detail below.

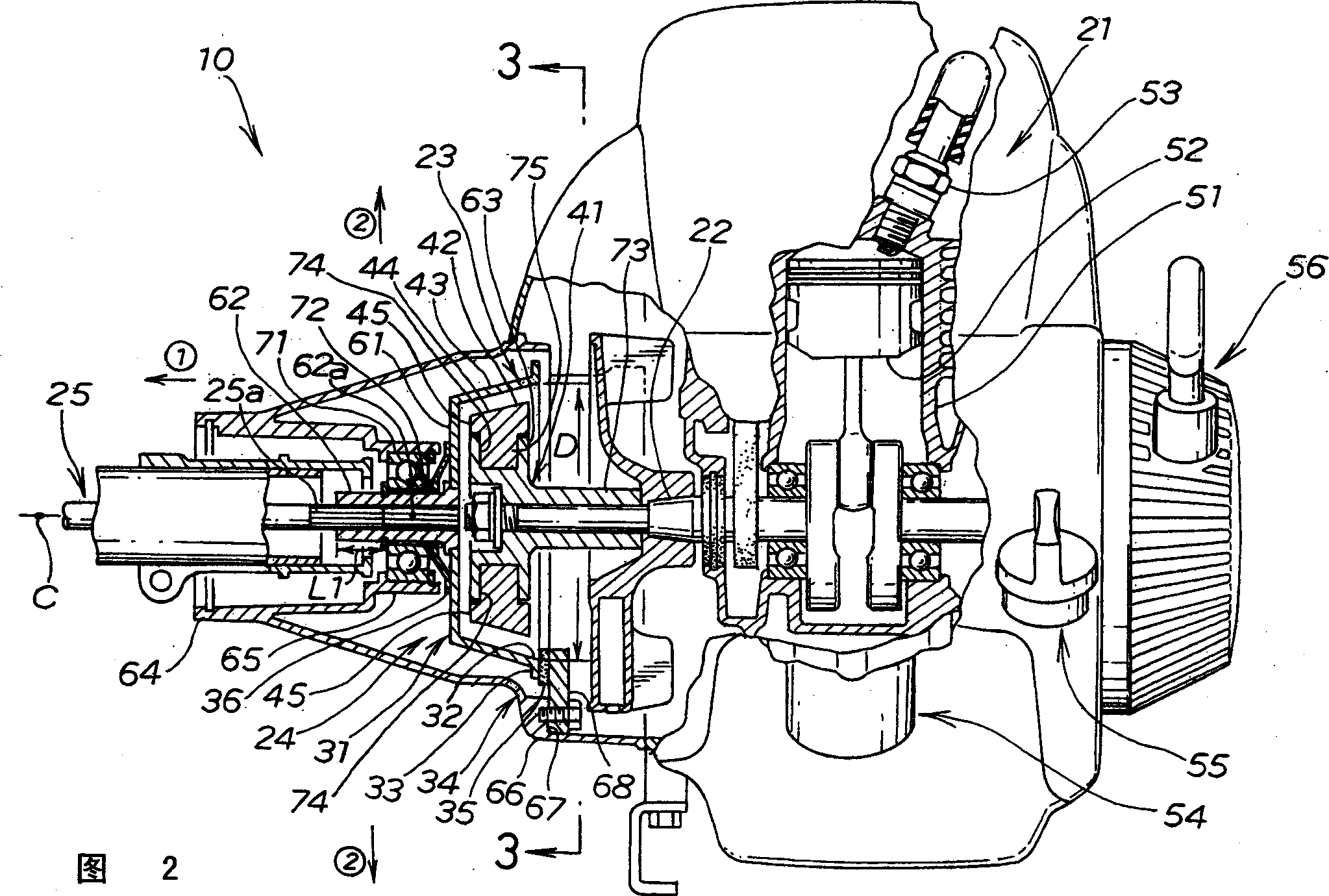

[0024] Figure 2 is figure 1 Partial sectional front view of the body section of the cutting device 10 circled by 2 in . As shown, the brush cutting apparatus 10 includes a prime mover or drive source 21 , a clutch mechanism 23 and a braking mechanism 24 connected to a crankshaft 22 of the drive source 21 , and a cutting blade drive shaft 25 connected to the clutch mechanism 23 .

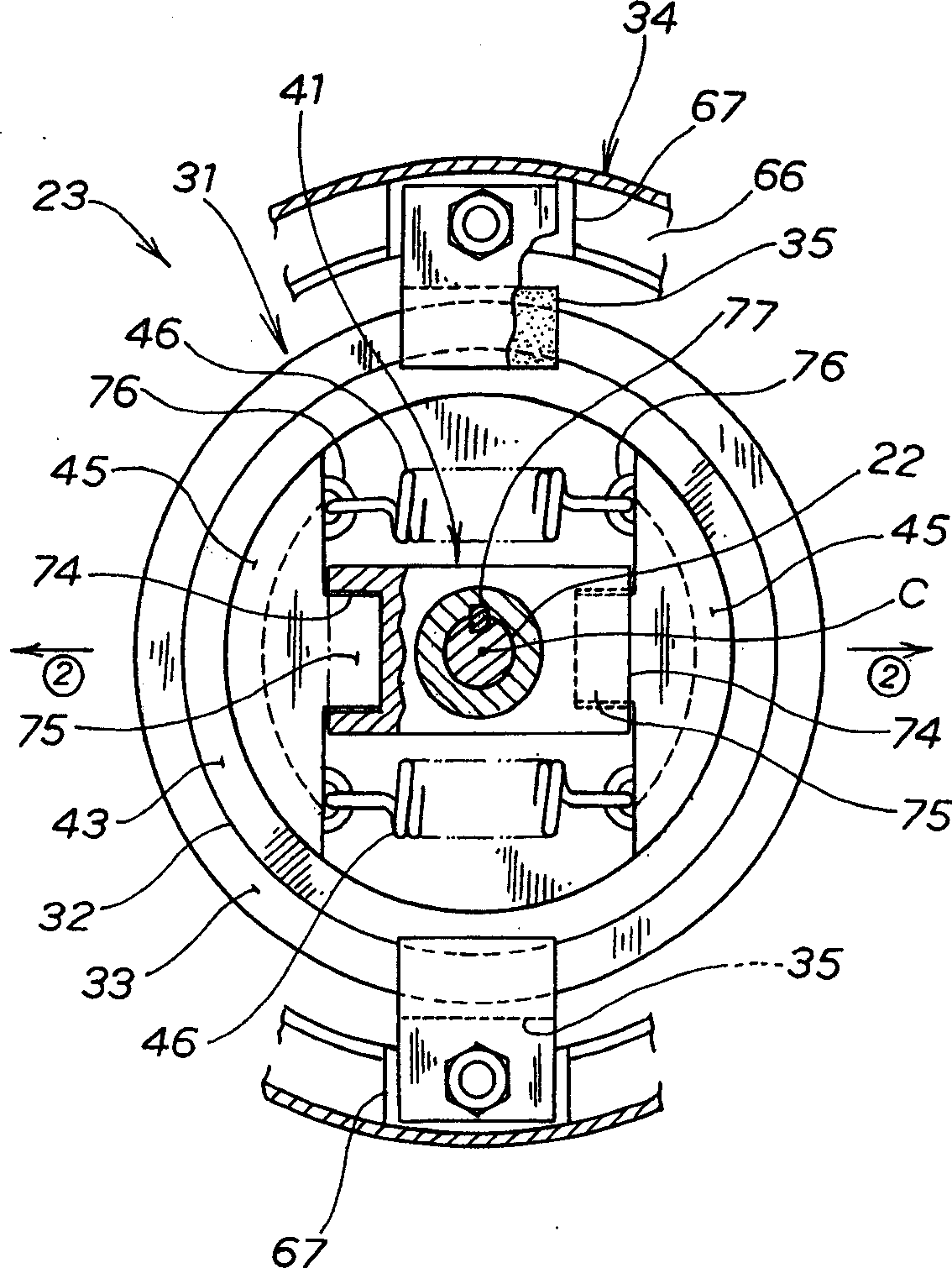

[0025]The clutch mechanism 23 includes a rotary element 41 mounted on the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com