Three-pivot seal testing device

A technology of sealing test and three fulcrums, which is applied in fluid tightness testing, measuring devices, engine sealing, etc., can solve problems such as poor rigidity of the spindle, high noise, and poor applicability, and achieve a wide range of axial and radial dimensions, Low vibration and noise, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

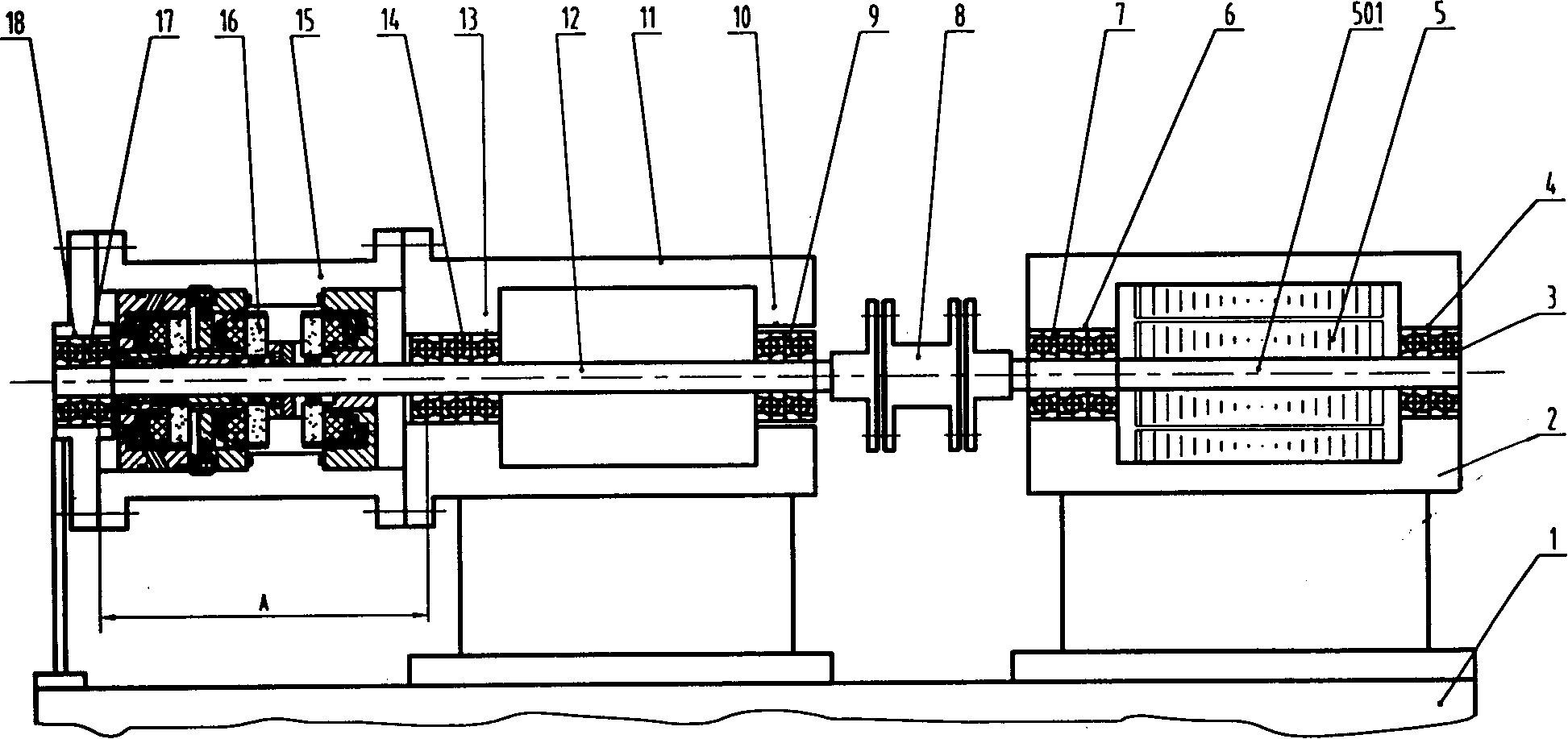

[0017] Example 1: Please refer to figure 1 , the housing 2 of the variable frequency speed regulating motor 5 is installed on the base 1, and a set of bearings 3, 7 are respectively installed at both ends of the base 1 through the fixed bearing seats 4, 6, and the two sets of bearings 3, 7 are used to support the variable frequency speed regulating motor 5 The motor shaft 501, the extended end of the motor shaft 501 is equipped with a coupling 8, and the end of the motor shaft 501 is connected with the seal test main shaft 12 through the coupling 8, and the seal test main shaft 12 is installed in the housing 11 and faces to the left The side protrudes from the housing 11, and the sealed chamber 15 to be tested and the seal to be tested 16 are installed on the left side of the housing 11. The above-mentioned sealing test main shaft 12 has a three-support structure, that is, it is supported by two sets of bearings 9, 14 installed in the casing 11 and a set of bearings 17 install...

Embodiment 2

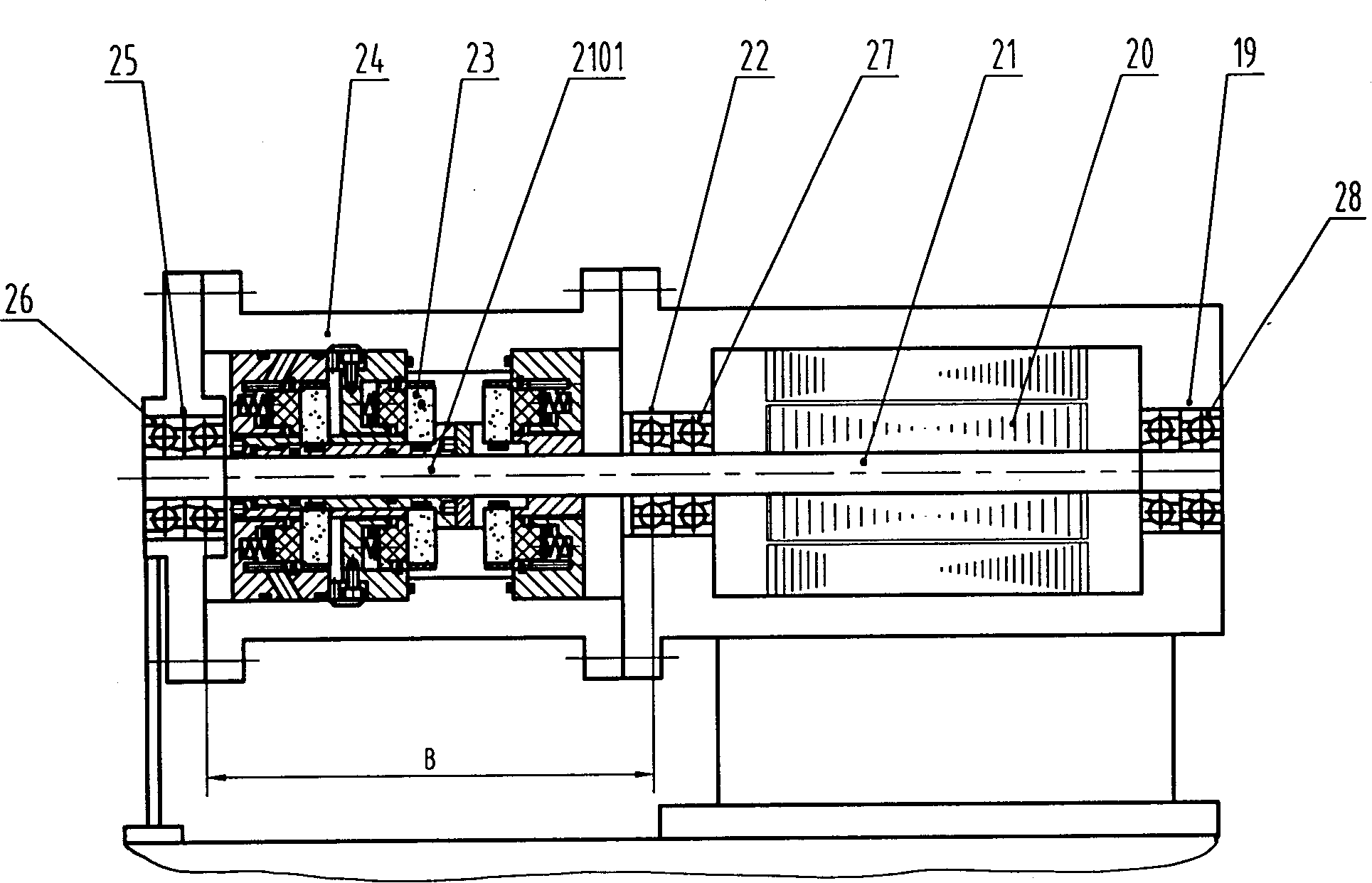

[0018] Example 2: Please refer to figure 2 , the part 2101 of the motor shaft 21 of the variable frequency speed regulating motor 20 protruding to the left is the main shaft of the sealing test. Three groups of bearings 28, 27, 26 are supported, and the sealed cavity 24 and one group of tested seals 23 are installed between the easy-to-disassemble bearing seat 25 and the front fixed bearing seat 22; The distance B between the bearings is in the range of 100-350 mm. In this figure, the number of bearings in the three bearing groups is 2, 2 and 2 from left to right, but the present invention is not limited to this arrangement, and the number of bearings in each group is 1 to 4 . Different from Embodiment 1, in this embodiment, the seal test spindle and the motor shaft are not independent of each other, but are the same shaft, and the part of the motor shaft extending to the left side is the seal test spindle. However, in these two embodiments, the essential features of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com