Device for cutting, extending and shifting elastic waistline

A transfer device and elastic waist technology, applied in transportation and packaging, medical science, textiles and papermaking, etc., can solve the problems of inconvenient adjustment, folding angle, insufficient waist elasticity, etc., and achieve convenient operation and maintenance, correct bonding position, and transfer The effect of process stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

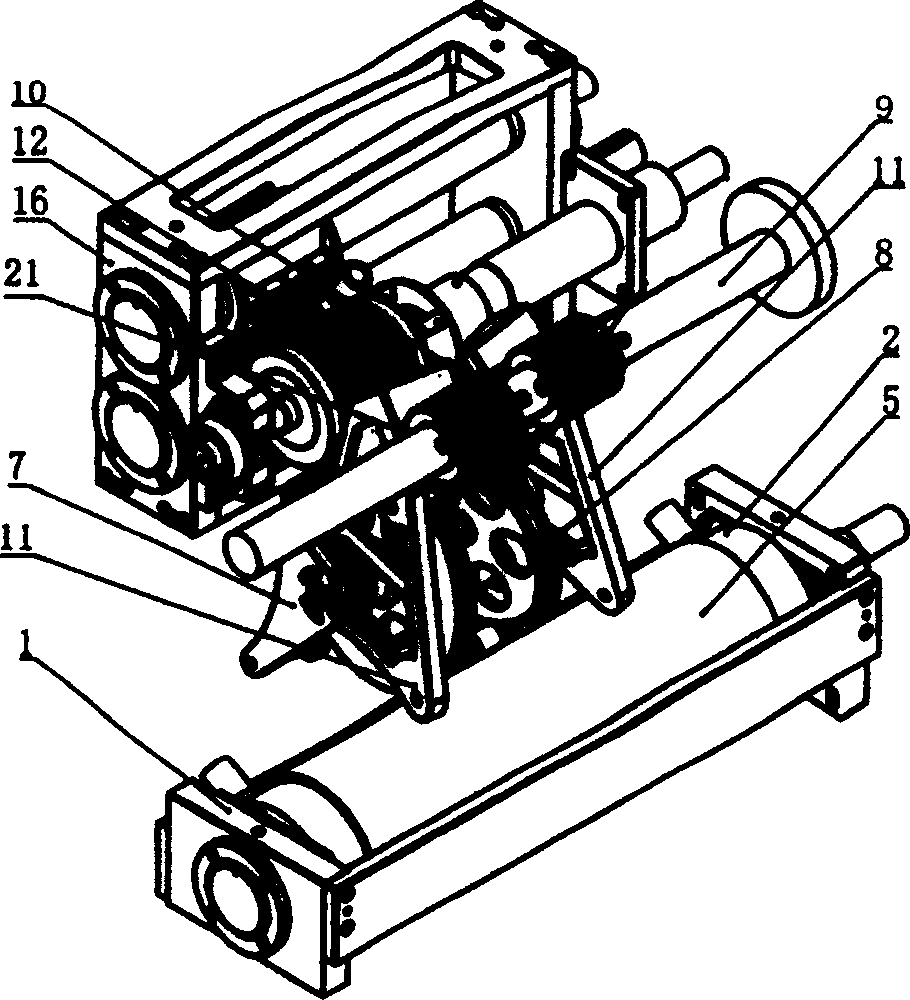

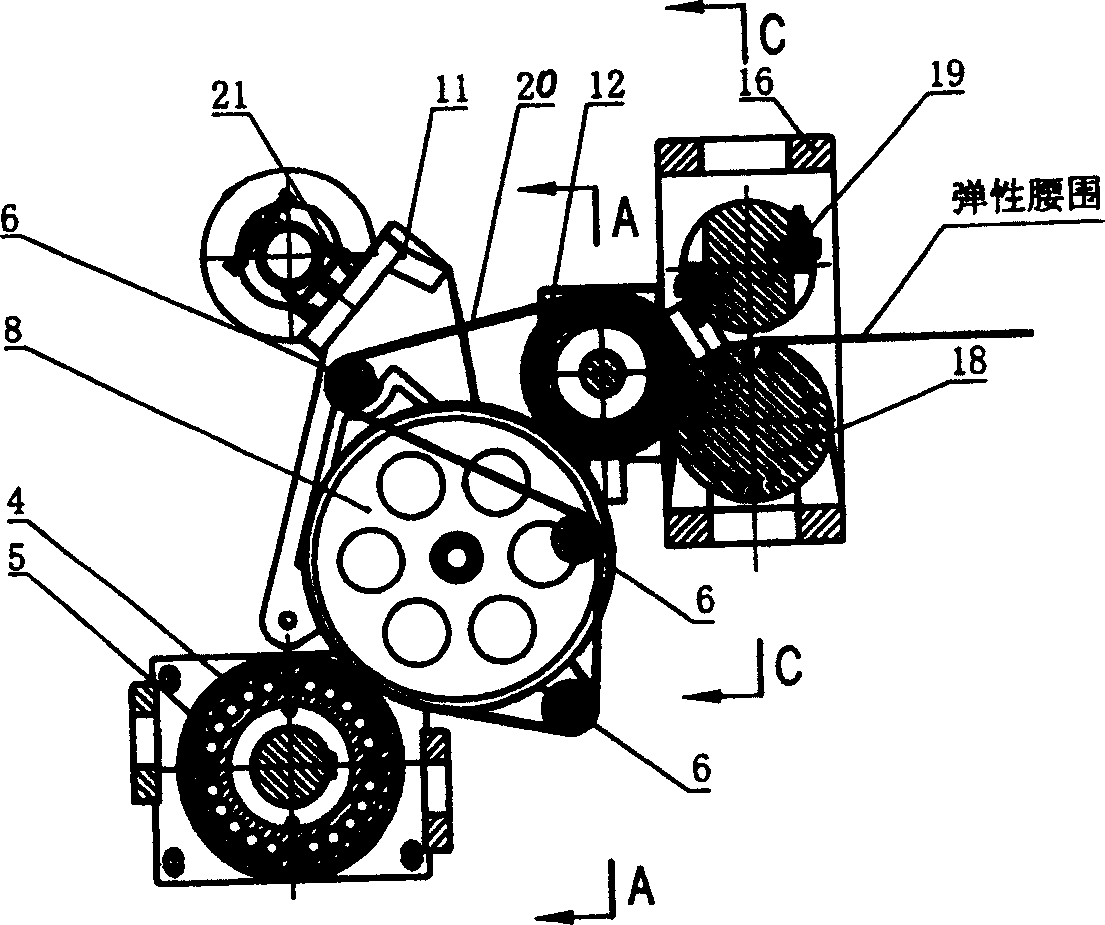

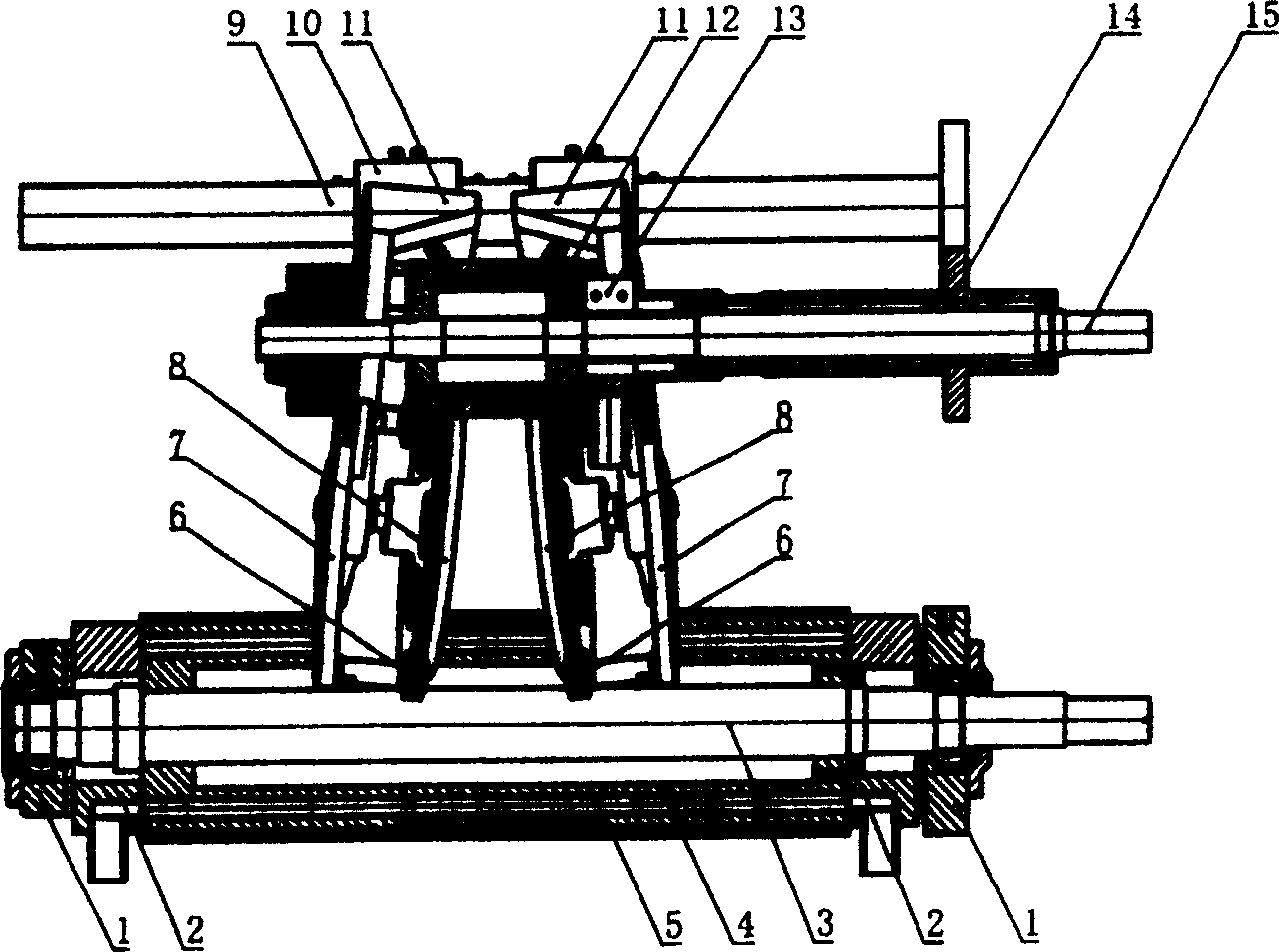

[0026] See figure 1 , figure 2 , image 3 and Figure 4 , The elastic waist cut-off stretch transfer device includes a frame, a cut-off transfer mechanism, a stretch mechanism and a transfer bonding mechanism. Cutting transfer mechanism comprises cutting tool rest 16, cutting knife roller 19, cutting bottom roller 18, cutting suction valve 17, suction roller suction valve 13, suction roller bearing seat 14, suction roller shaft 15 and suction roller 12.

[0027] The stretching mechanism includes a pair of splayed wheels 8; the splayed wheel side plate 11 is triangular, the splayed wheel 8 is arranged at the lower corner of the triangular splayed wheel side plate 11 through the wheel shaft, and the upper corner of the triangular splayed wheel side plate 11 is connected to The 90-degree rotatable positioning sleeve connecting plate 21, the eight-character wheel side plate 11 is connected with the positioning sleeve connecting plate 21 by two screws, the eight-character wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com