Device and method for w shape flame boiler completely burning

A technology of burning out wind and flames, applied in combustion equipment, lighting and heating equipment, etc., can solve the problems of reduced combustion efficiency, unstable combustion, poor combustion effect, etc., to increase the combustion rate, increase the residence time, and improve the combustion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

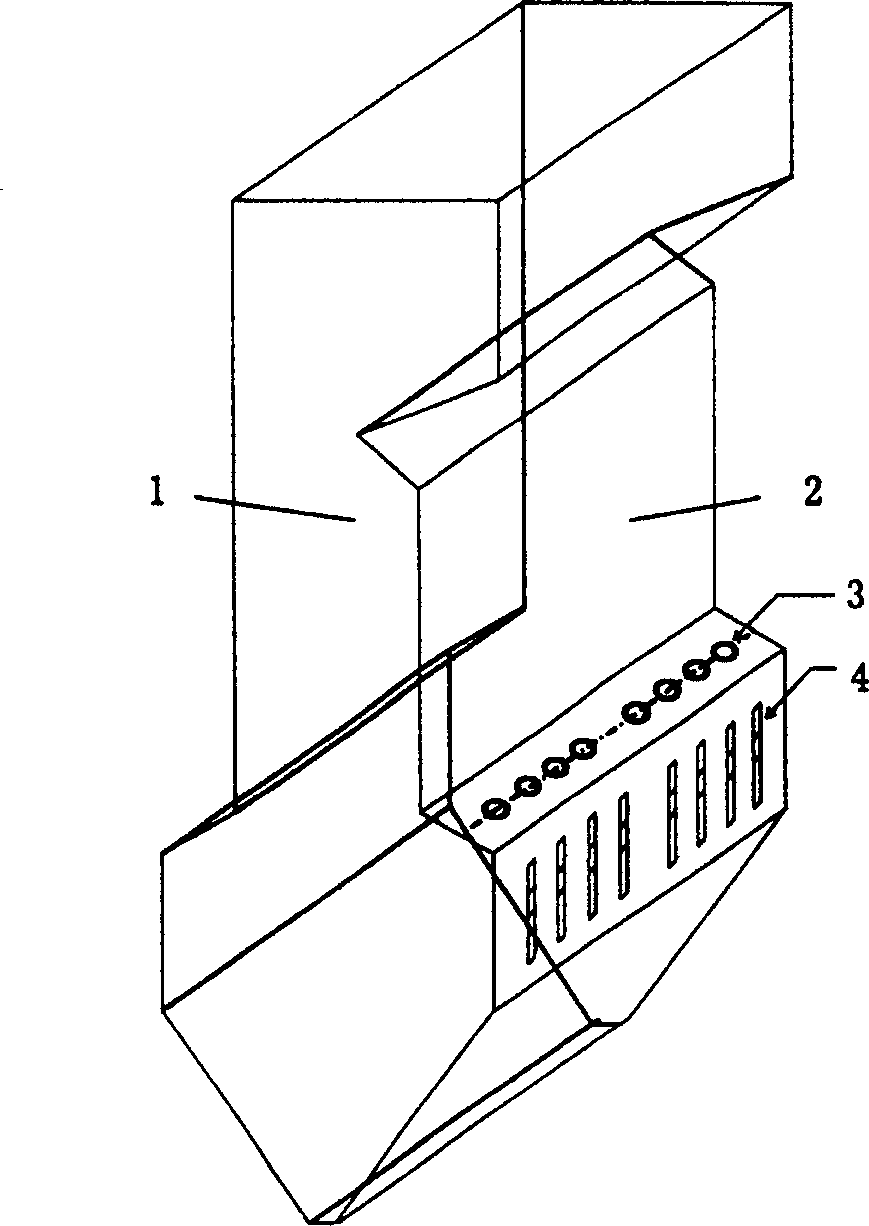

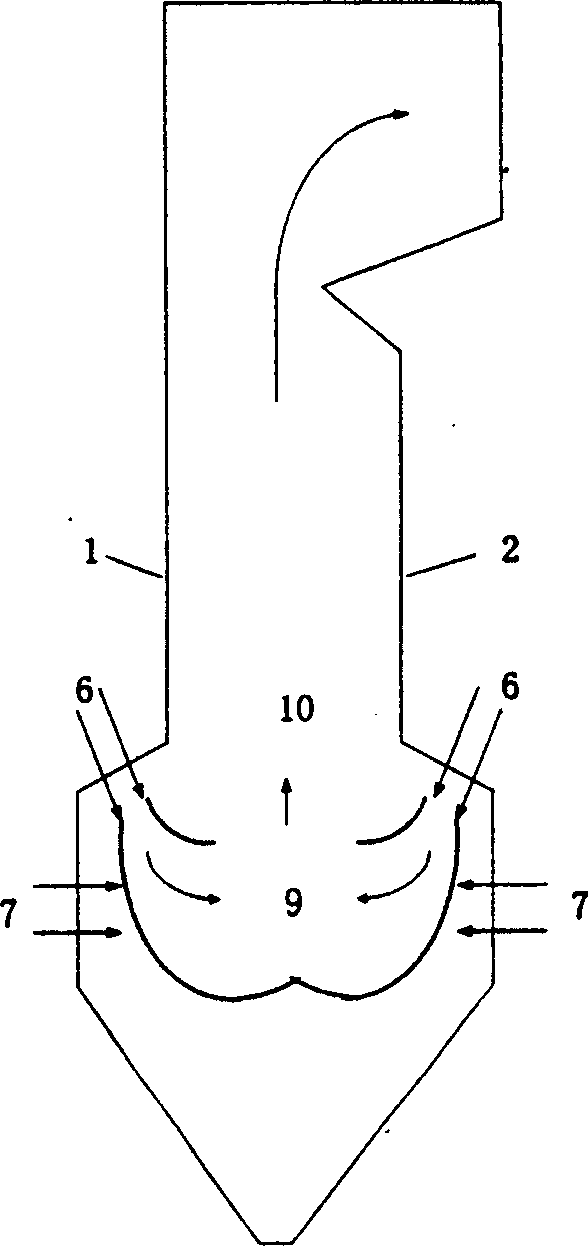

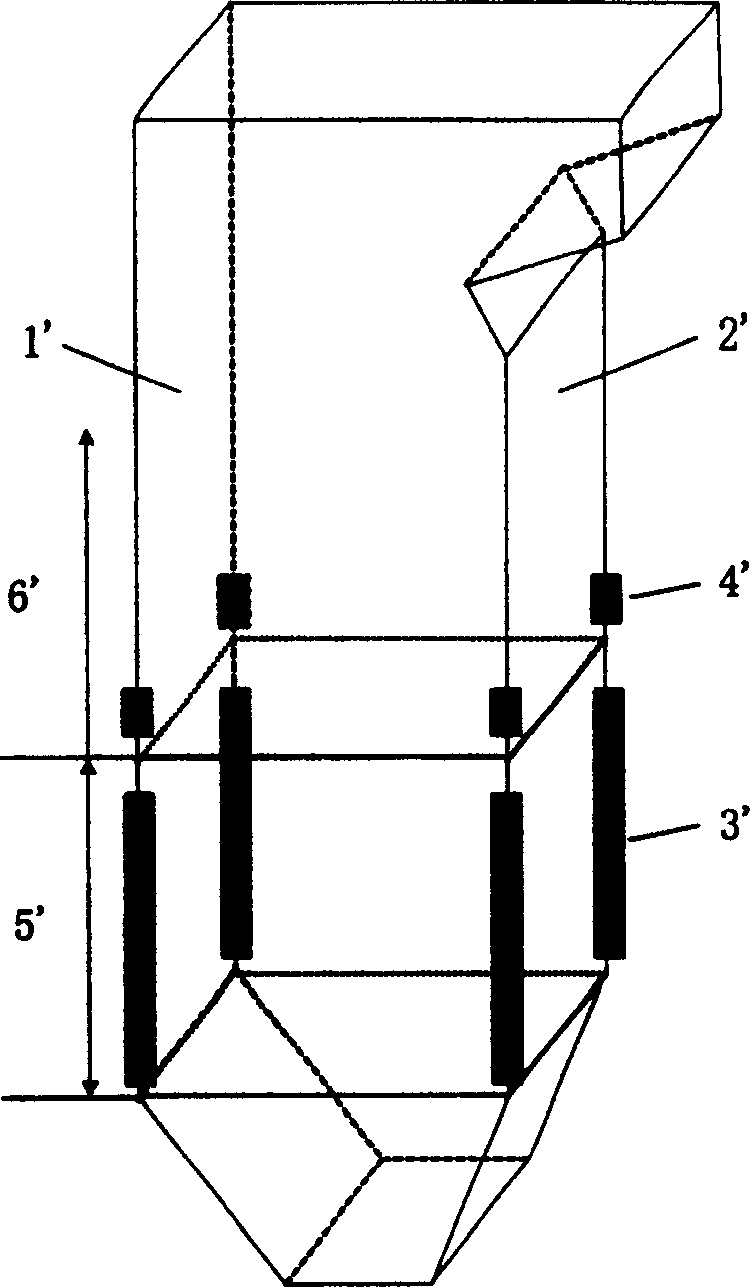

[0016] The structure of the W-type flame boiler with exhausted air is as attached Figure 4 As shown in the figure, the burner only draws the rear wall part, the front wall is symmetrically arranged, the front wall 1, the rear wall 2, the primary air and secondary air nozzles 3 are located on the front and rear wall arches, and the tertiary air nozzle 4 is located in the lower furnace vertical On the front and rear walls, the exhaust air nozzle 5 is located at the upper throat of the primary air pulverized coal nozzle of the burner on the front and rear wall arches. W-type flame boilers with different capacities produced by different companies have different types and numbers of burners, so the number and size of burnout vents are also different, which requires specific design. The shape of the burnout air nozzle 5 is not limited. The cross-section and flow field of the W-type flame boiler with exhausted air are attached Figure 5 As shown, the direction of the arrow in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com