Method for producing serially combined voltage-equalizing anti-explosion arrester

A lightning protection device and independent unit technology, applied in the direction of overvoltage arresters, electrical components, spark gaps, etc. that apply spark gaps, can solve problems such as explosion accidents, reduce insulation strength, reduce residual voltage values, and improve protection functions and safety The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

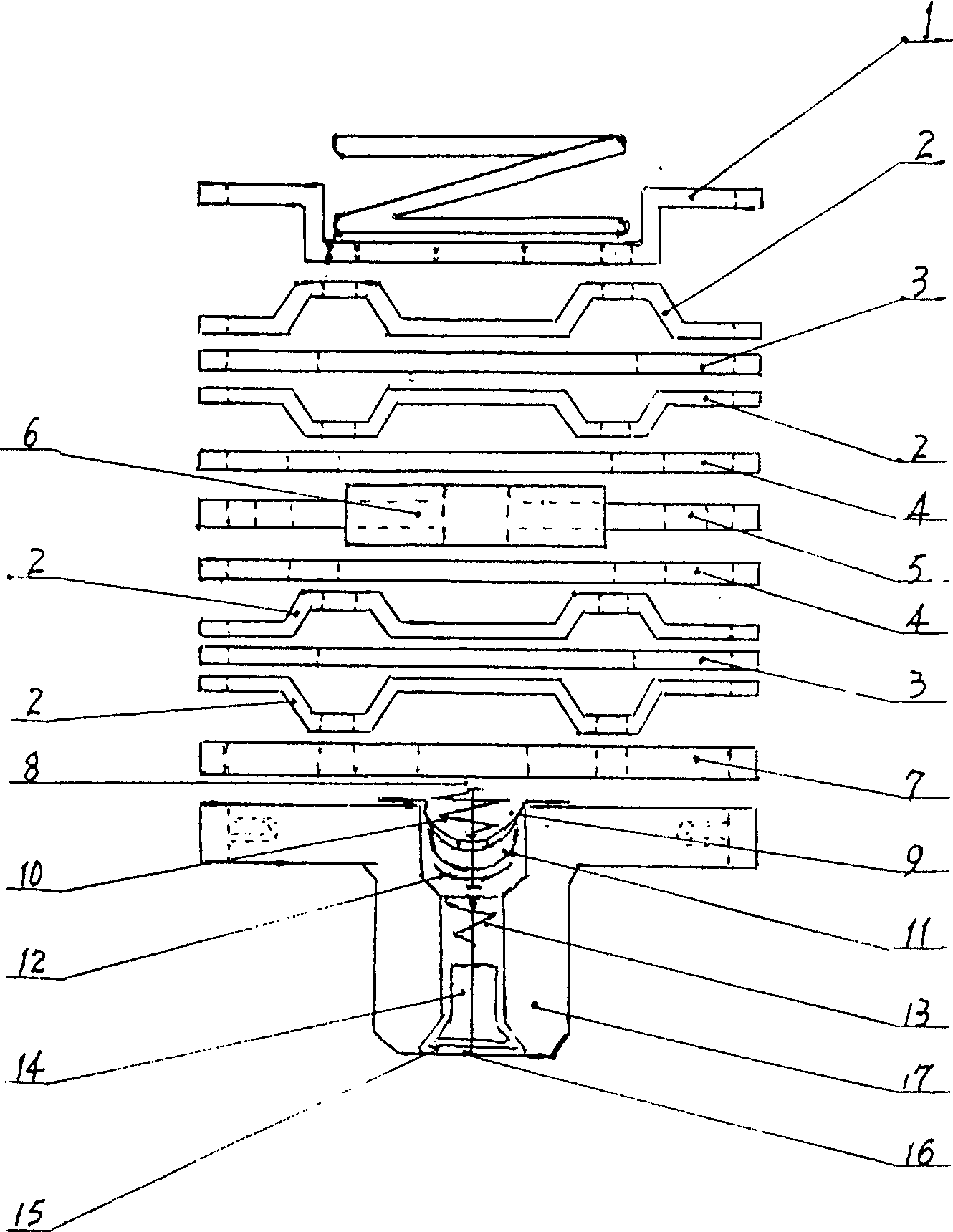

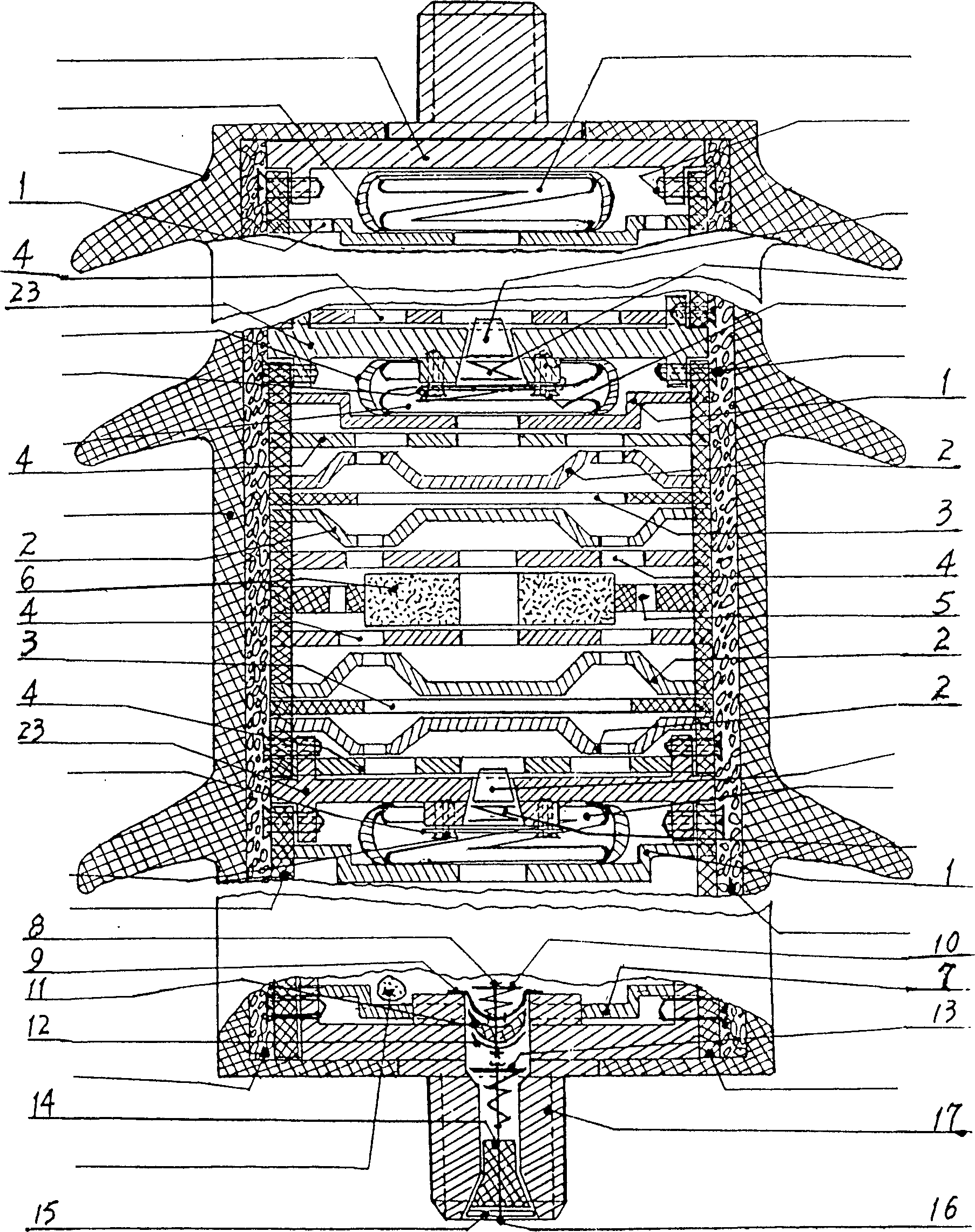

[0045] Such as image 3 As shown, it is a three-unit combined explosion-proof arrester. This embodiment is suitable for each independent unit discharge voltage is 3.3KV, and its combined overall voltage is 10KV explosion-proof and lightning protection device. It is composed of three groups of units combined in series, gap pressure equalization and explosion-proof main part and fixed sealing shell part; the main part is composed of three units, and the structure of the upper, middle and lower units is roughly the same.

[0046] The main part of each unit is as image 3 Shown: The effective discharge large-plane porous ventilated discharge gap valve group (2) clamps the hollow insulating gasket (3) to form an effective discharge large-plane porous ventilated discharge gap valve group, which is inlaid and bonded in series with the surrounding waist. The center of the insulating arc-shielding positioning garden disc (5) has a vent hole and sticks a hollow ventilated zinc oxide r...

Embodiment 2

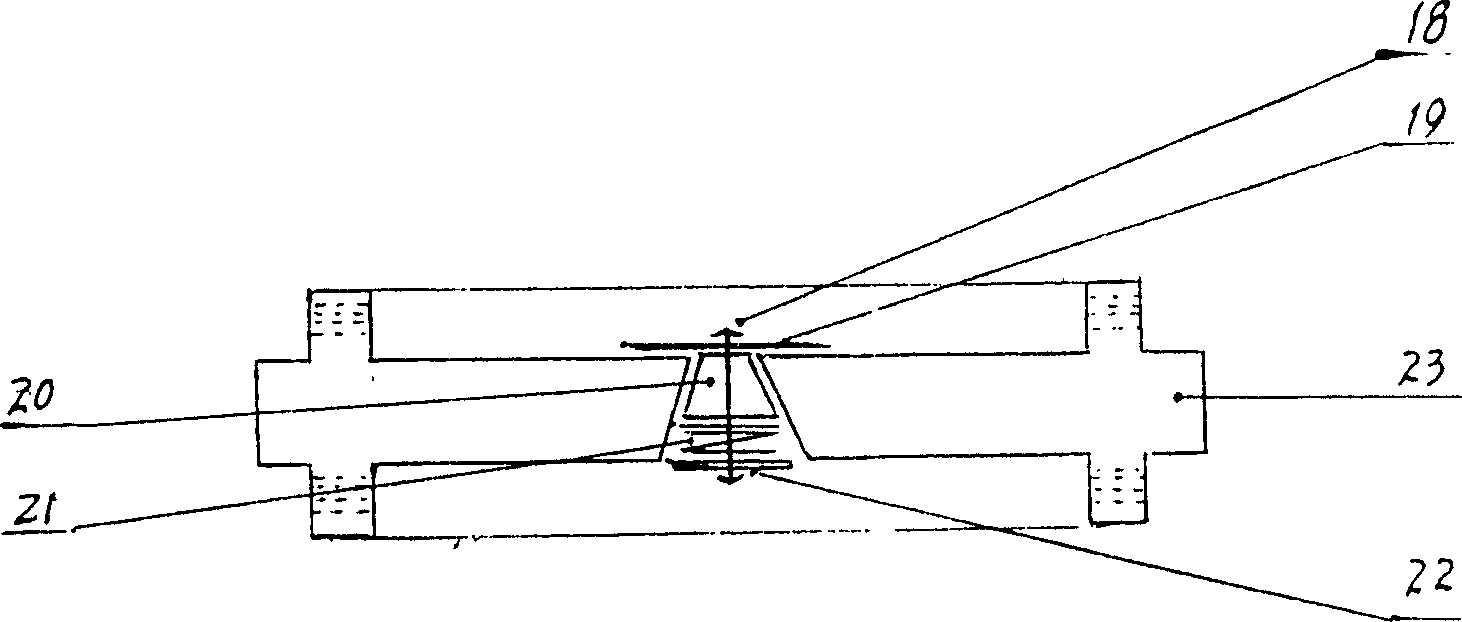

[0053] Such as Figure 4 As shown, this embodiment is a lightning protection and explosion-proof insulator with a discharge voltage of 3KV per independent unit.

[0054] The effective discharge large-plane porous ventilating discharge gap valve piece (2) is made of stainless steel, with an effective cross-sectional area of 816 square millimeters and a thickness of 1.8 millimeters. The thickness of the hollow insulating washer (3) is 3 millimeters. The thickness of ventilating type insulating arc-shielding positioning garden disc (5) is 2.5 millimeters. The middle hole ventilation type zinc oxide resistance (6) is zinc oxide, and the thickness is 15 millimeters.

[0055] Its structural components are basically the same as in Embodiment 1.

[0056] The discharge voltage of the explosion-proof lightning protection insulator of the power lightning protection line is 3KV, and the tensile force is 70KN. The simulated lightning strike is 4 / 10us high-current impact, the maximum c...

Embodiment 3

[0058] This embodiment is an explosion-proof and lightning protection device with a discharge voltage of 1KV per independent unit.

[0059] The effective discharge large-plane porous ventilating discharge gap valve piece (2) is made of stainless steel, with an effective cross-sectional area of 325 square millimeters and a thickness of 0.6 millimeters. The thickness of the hollow insulating washer (3) is 0.9 mm. The thickness of the ventilation type insulating arc shielding positioning garden disk is 1.2 millimeters. The middle hole ventilation type zinc oxide resistance (6) is zinc oxide, and the thickness is 12 millimeters.

[0060] The main part of this embodiment is composed of one unit. Its structural components are basically the same as in Embodiment 1.

[0061] The discharge voltage of the electric lightning protection line is 1KV, the tensile force is 70KN, the simulated lightning strike is 4 / 10us high current impact, the maximum current is 43.42KA, the total resid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com