Wind power device

A technology of wind power equipment and wind direction, applied in the direction of mechanical equipment, wind power engine, wind power motor combination, etc., can solve problems such as asymmetry, achieve the effect of suppressing spring effect, simple torque control, and suppressing undesired effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

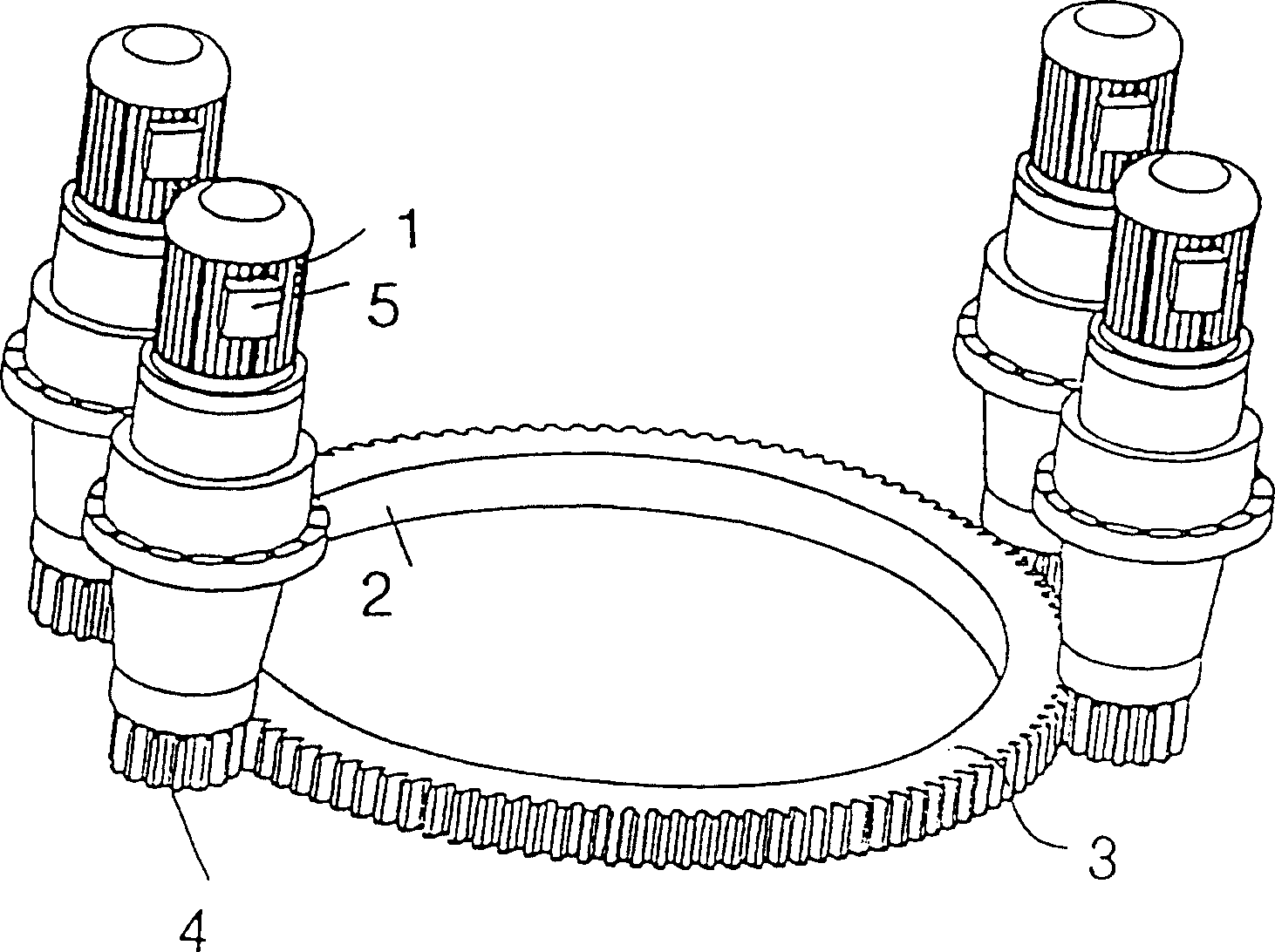

[0035] Wind power plants often have dynamic drives for wind direction tracking. The dynamic drive turns the nose of the wind turbine so that the rotor blades of the rotor are optimally positioned in the direction of the wind. The dynamic drive used for wind direction tracking is an azimuth drive 1 with associated azimuth bearing 2 and is usually arranged between the tower top and the casing. In the case of small wind turbines, one azimuth drive is sufficient, while large wind turbines usually have several drives, e.g. figure 1 The four drives shown in . The four drives are evenly distributed along the perimeter of the tower top 3 (a non-uniform distribution is also possible).

[0036] During operation of wind power plants in strong winds, depending on the angle of rotation of the rotor, very large forces are generated and associated with this high and frequent load peaks in the azimuth drive.

[0037] If the movement device used to move the handpiece has more than one azim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com