Paper size detecting mechanism

A paper size and paper tray technology, applied in the field of size detection mechanism that automatically detects the size of documents to be scanned, can solve problems such as misjudgment, complicated paper classification and judgment, and failure to meet the use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

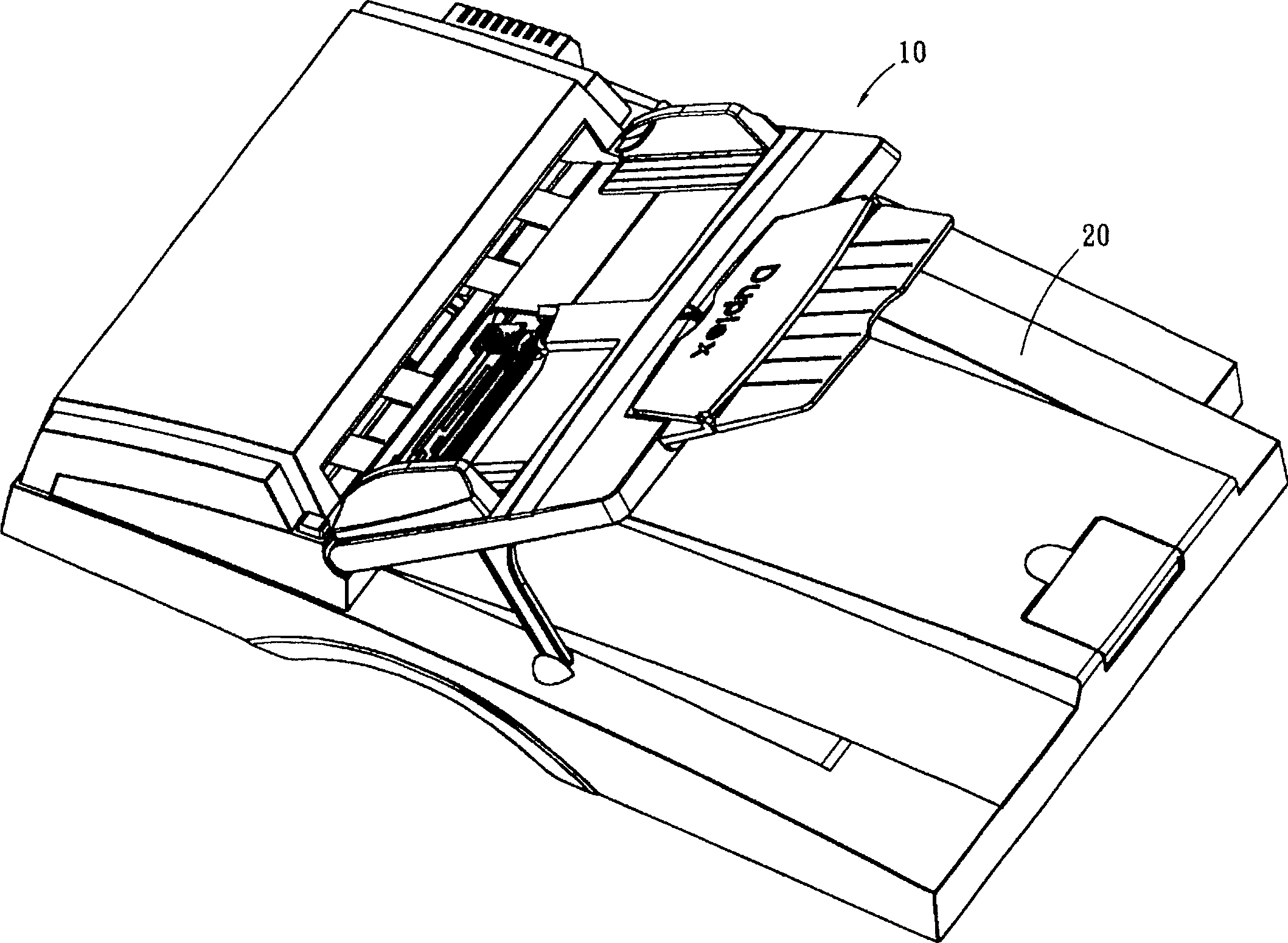

[0042] Such as figure 1 As shown, an automatic document feeder module includes a paper input tray 10 and an output tray 20 . The paper tray 10 can be used for placing documents to be scanned, and can cooperate with the paper feeding mechanism to automatically feed the documents.

[0043] Such as figure 2 As shown, the paper tray 10 includes a paper tray 12 and two opposite paper guides 14 , 16 . One surface of the paper tray 12 is defined as a paper placement surface 13 , and the paper placement surface 13 is used as a position for placing paper. The surface opposite to the paper surface 13 is defined as the bottom surface 15 .

[0044] The two opposite paper guides 14 , 16 are set on the paper tray 12 and protrude from the paper surface 13 . The two paper guides 14, 16 can approach or move away from each other as they move.

[0045] Such as image 3 and Figure 4 As shown, an induction component module 30 is fixed on the bottom surface 15 of the paper tray 12 . The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com