Movable floor block and support keel, and movable floor system composed of them

A technology of access floor and floor boards, which is applied in the field of building decoration materials, can solve the problems of inconvenient disassembly, waste of man-hours, damage to ground strength, etc., and achieve the effect of convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

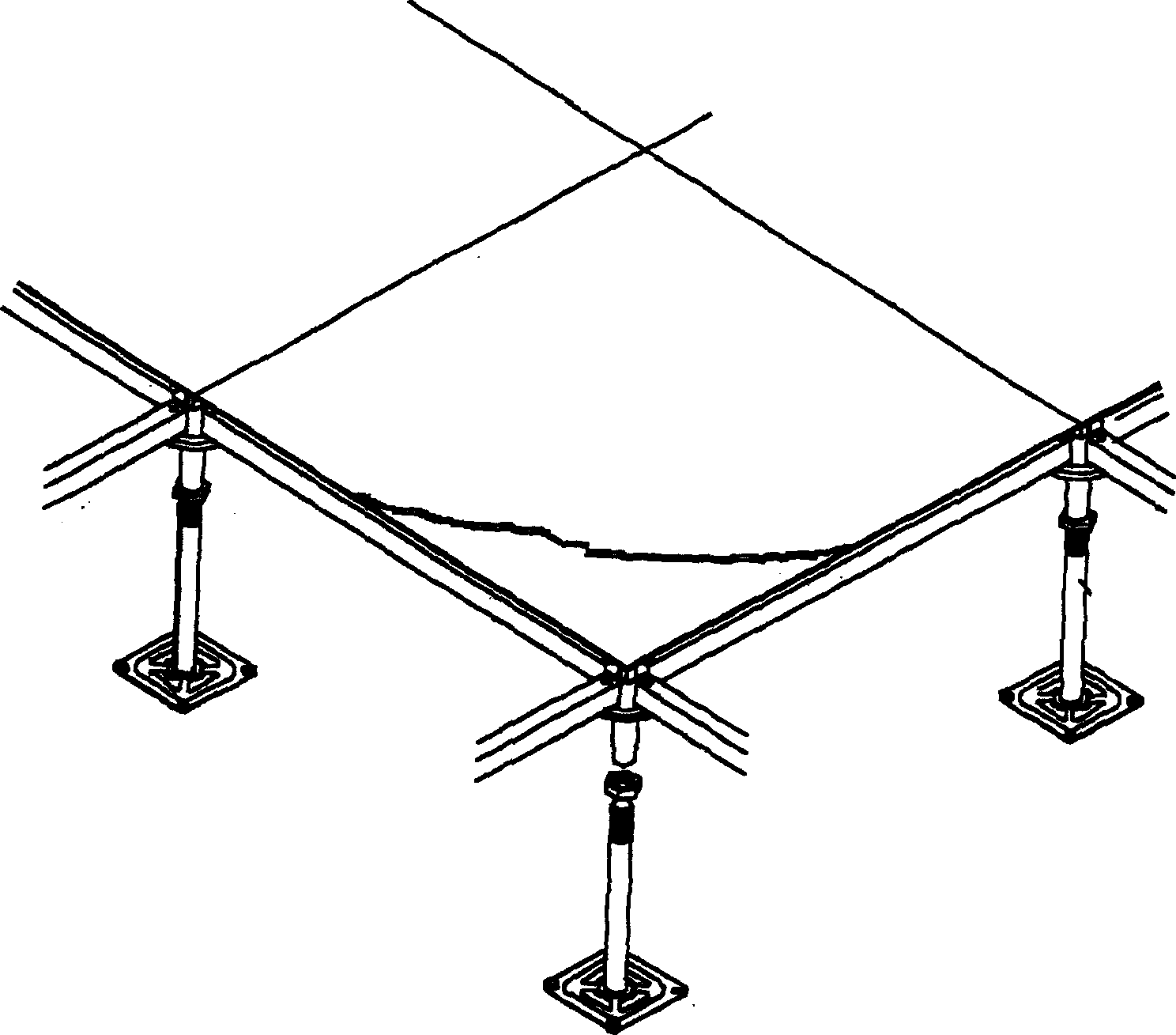

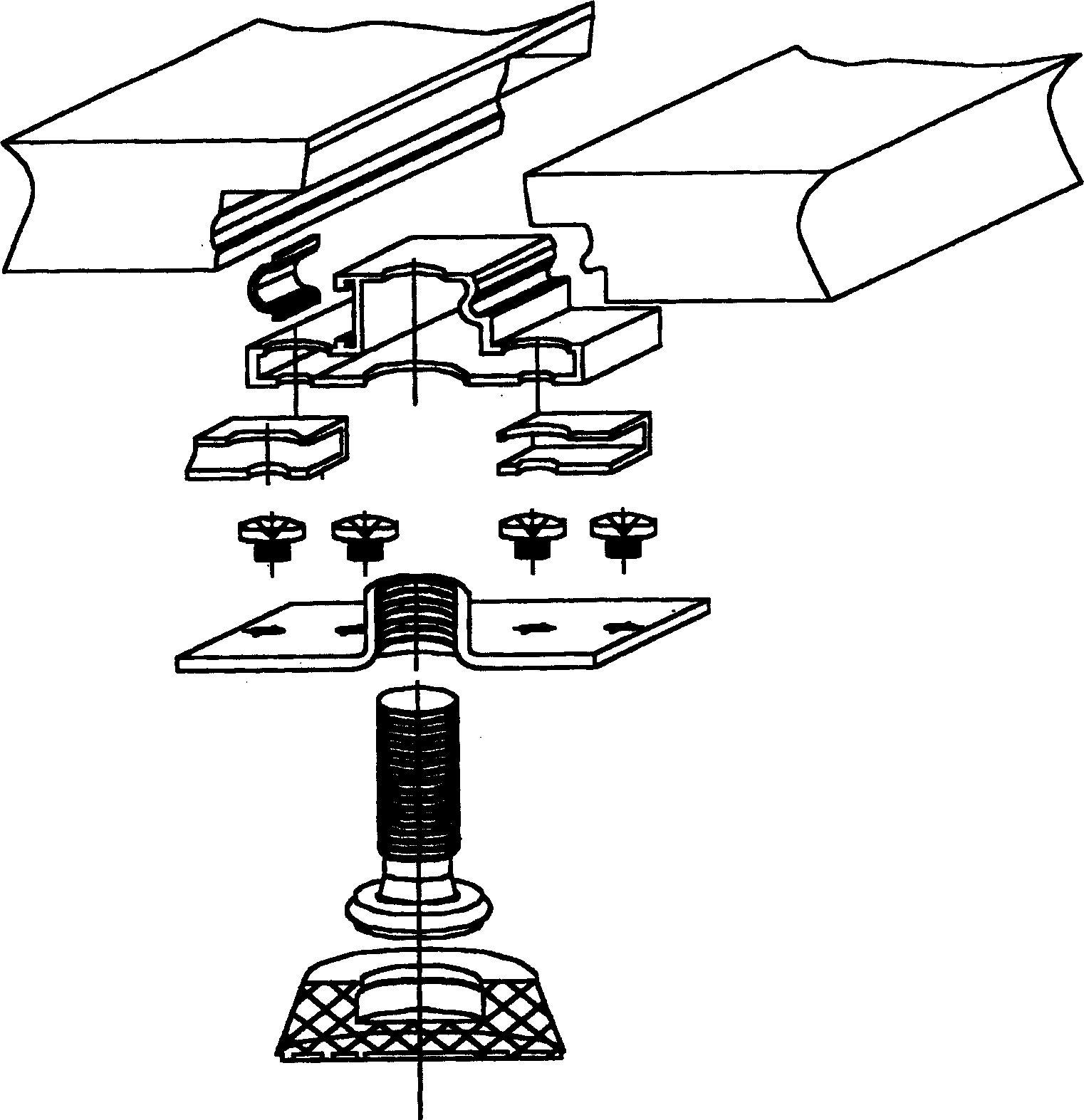

Embodiment 1

[0084] Embodiment one: if Figure 4 -6 shown. The supporting rod 4 is fixed on the supporting base 6 made of rubber material, the supporting rod 4 is an adjusting screw rod, the external thread of the supporting rod 4 is connected with the tray 5, the keel 2 is arranged above the supporting rod 4, and the two sides of the keel 2 are respectively close to the corresponding On the sides of two adjacent raised floor boards 1, the sides of the keel 2 extend downward and are fixed on the upper surface of the pallet 5 close to the support bar 4, the beam 3 is fixed on the upper surface of the outer side of the pallet 5, and the lower bottom surface of the raised floor board 1 is placed On the upper surface of the extended side of the beam 3 and the side of the keel 2, a card slot 21 is fixed on one side of the keel 2, and a protruding spring piece 7 is embedded in the card slot 21, and the spring piece 7 is embedded in the side of the corresponding raised floor board 1. The other s...

Embodiment 2

[0085] Embodiment two: if Figure 7 -9. The difference from Embodiment 1 is that both sides of the keel 2 are concavely formed with keel grooves 22, while the floor beams in Embodiment 1 are changed to elastic bumps 111 arranged on the side of the movable floor board 1, and the elastic bumps 111 is made of elastic material such as rubber, the elastic bump 111 is elastically connected with the spring seat 113 fixed in the movable floor board 1 through the spring 112, and the convex end of the elastic bump 111 is embedded in the corresponding keel groove 22; The upper surface of the extended side of the keel side of the upper surface of the tray 5 has an upwardly protruding inlaid beam 24 embedded in the corresponding inlaid groove 14 provided on the bottom surface of the raised floor board 1 . Through the fit between the elastic protrusion 111 and the keel groove 22 and the inlaid beam 24 and the inlaid groove 14, the connection between the movable floor board 1 and the keel 2...

Embodiment 3

[0086] Embodiment three: as Figure 10 , 11 . Compared with Embodiment 1, the two sides of the keel are provided with card slots 21, and the card slots 21 are embedded with protruding spring pieces 7, and are respectively embedded in the floor grooves 12 on both sides of the corresponding two movable floor boards 1. middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com