Separation method of dimethyl ether prepared with synthetic gas through one-step process

A separation method and technology of dimethyl ether, applied in ether preparation, organic chemistry and other directions, can solve the problems such as failure to meet design indicators, recovery rate of less than 95%, and insufficient concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

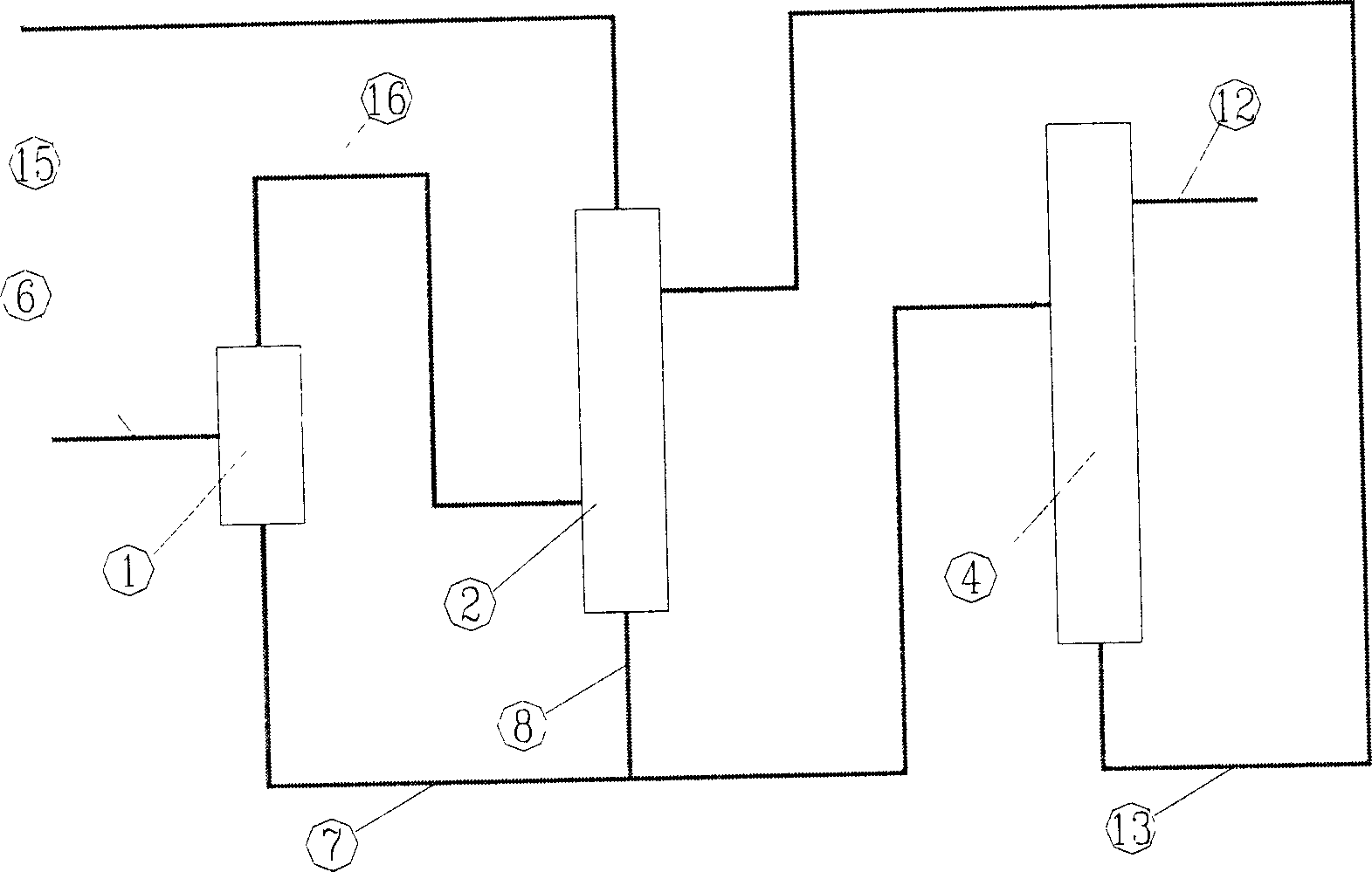

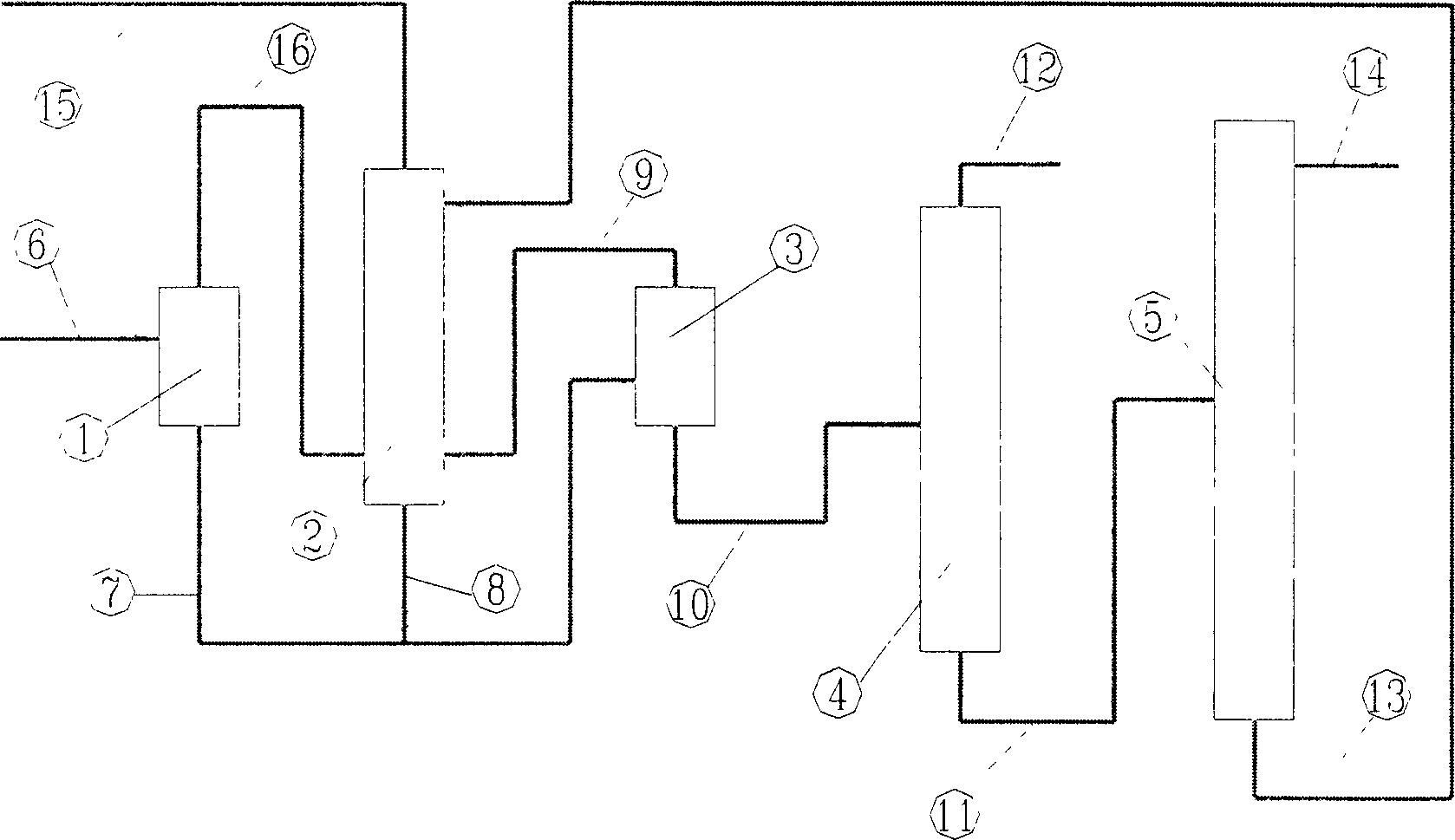

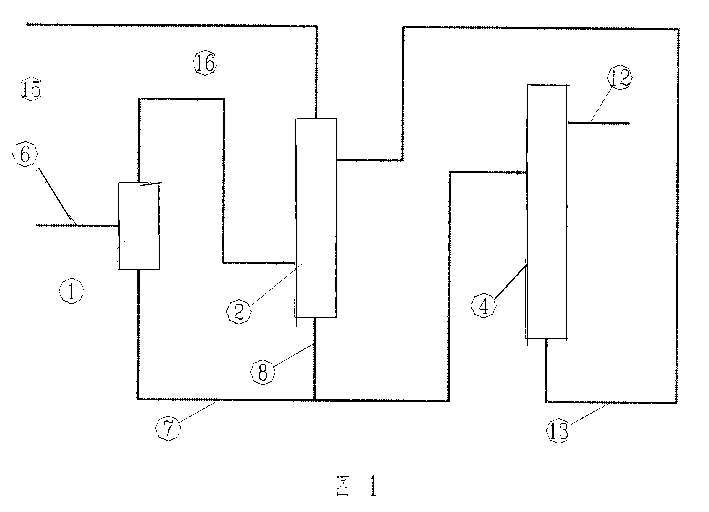

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: Table 1 is the data of each stream product in the separation process of raw material 1.

Embodiment 2

[0023] Embodiment 2: Table 2 is the data of each stream product in the separation process of raw material 2.

[0024] Stream 12 in the above two tables is dimethyl ether, reaching 99.16% and 99.39% respectively.

[0025] Table 1:

[0026] Logistics serial number

6

7

8

9

10

11

12

13

14

15

16

components

V%

H 2

.0591

.0003

0

.0024

0

0

0

0

0

.0851

.0776

N 2

.0527

.0003

0

.0021

0

0

0

0

0

.0758

.0691

CO

.1851

.0018

.0001

.0101

0

0

0

0

0

.2664

.2426

CO 2

.1926

.0288

.0021

.2053

.0002

0

.0083

0

0

.2752

.2440

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com