Floor mop

A technology of mop and mop rod, which is applied in the field of mop and can solve problems such as difficulties in the extrusion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

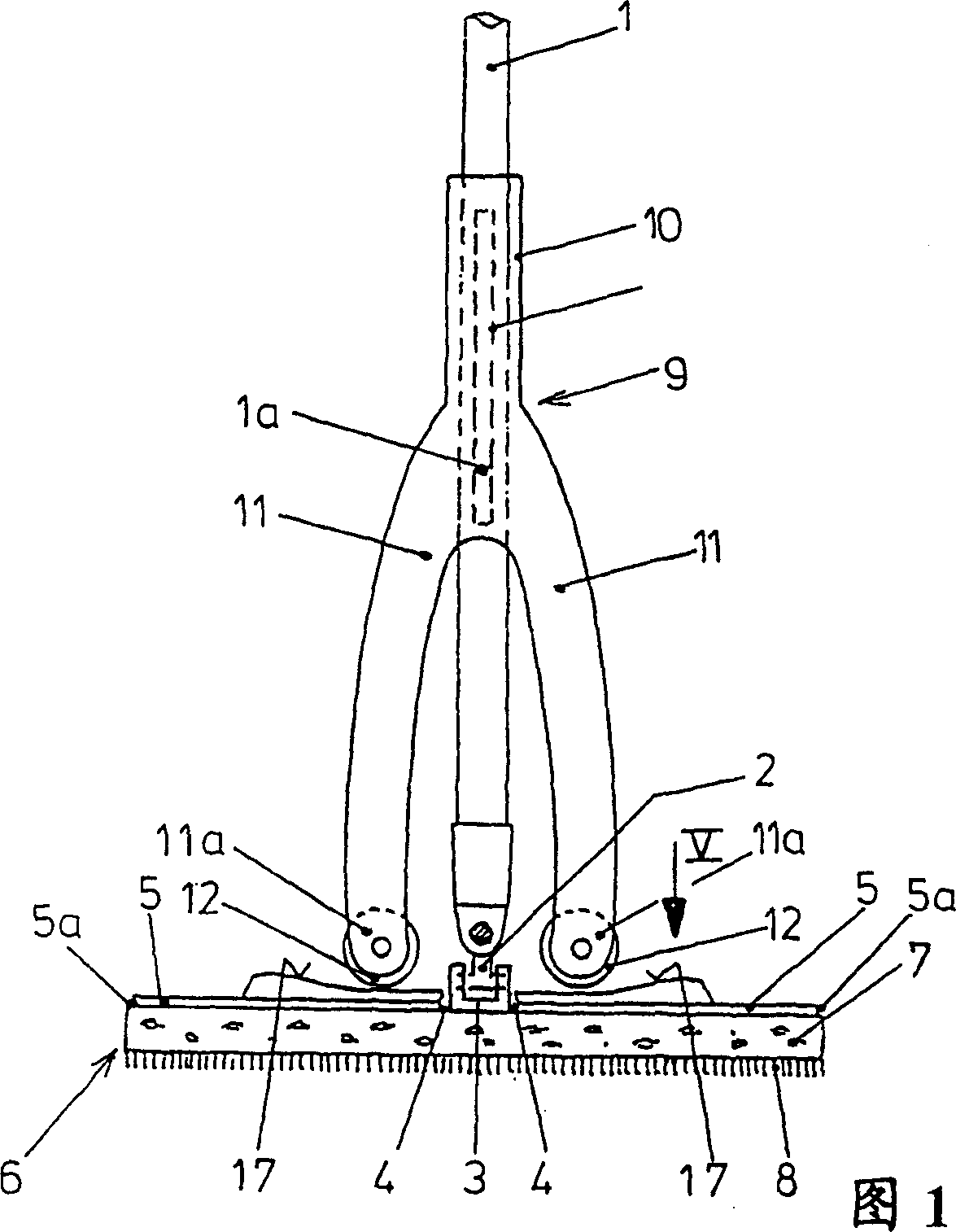

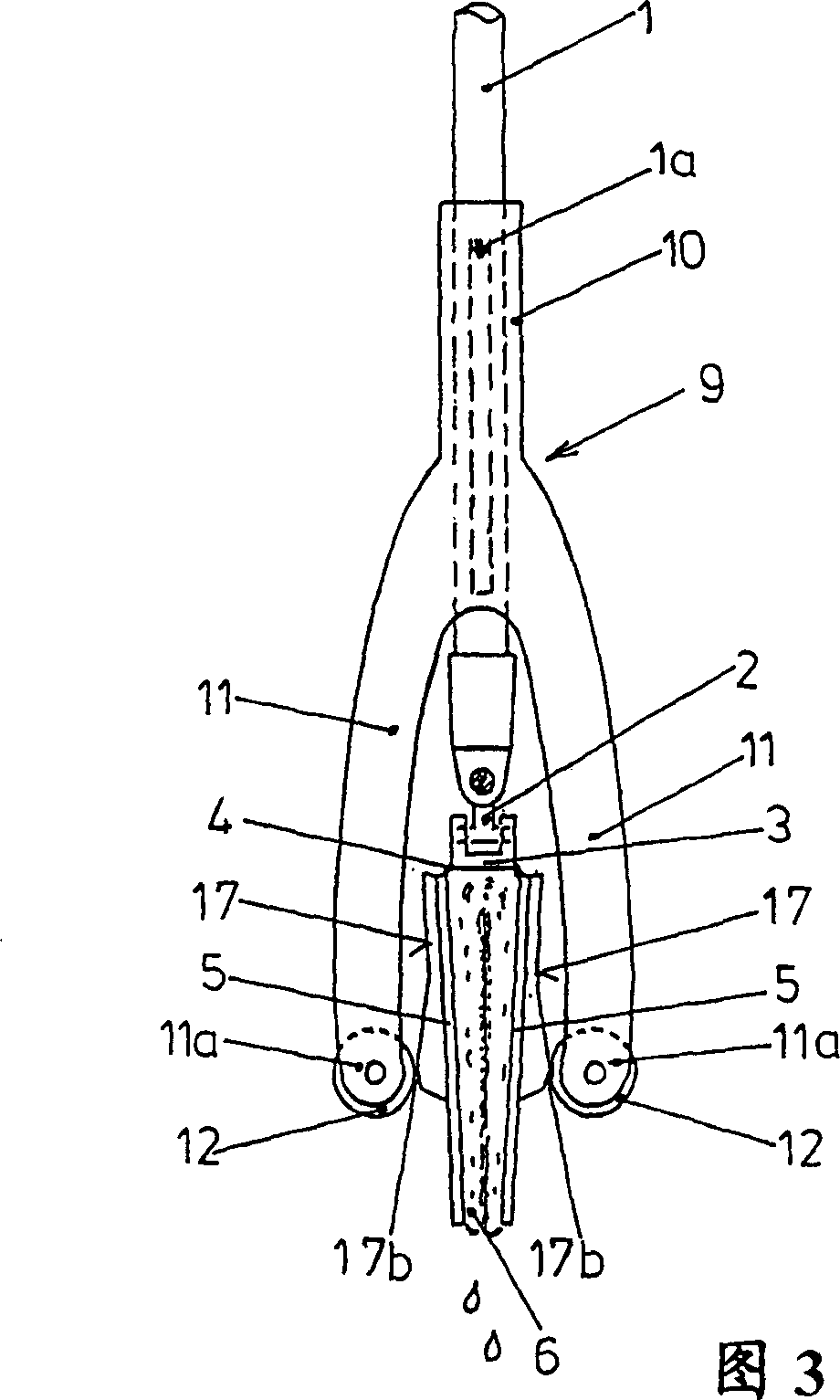

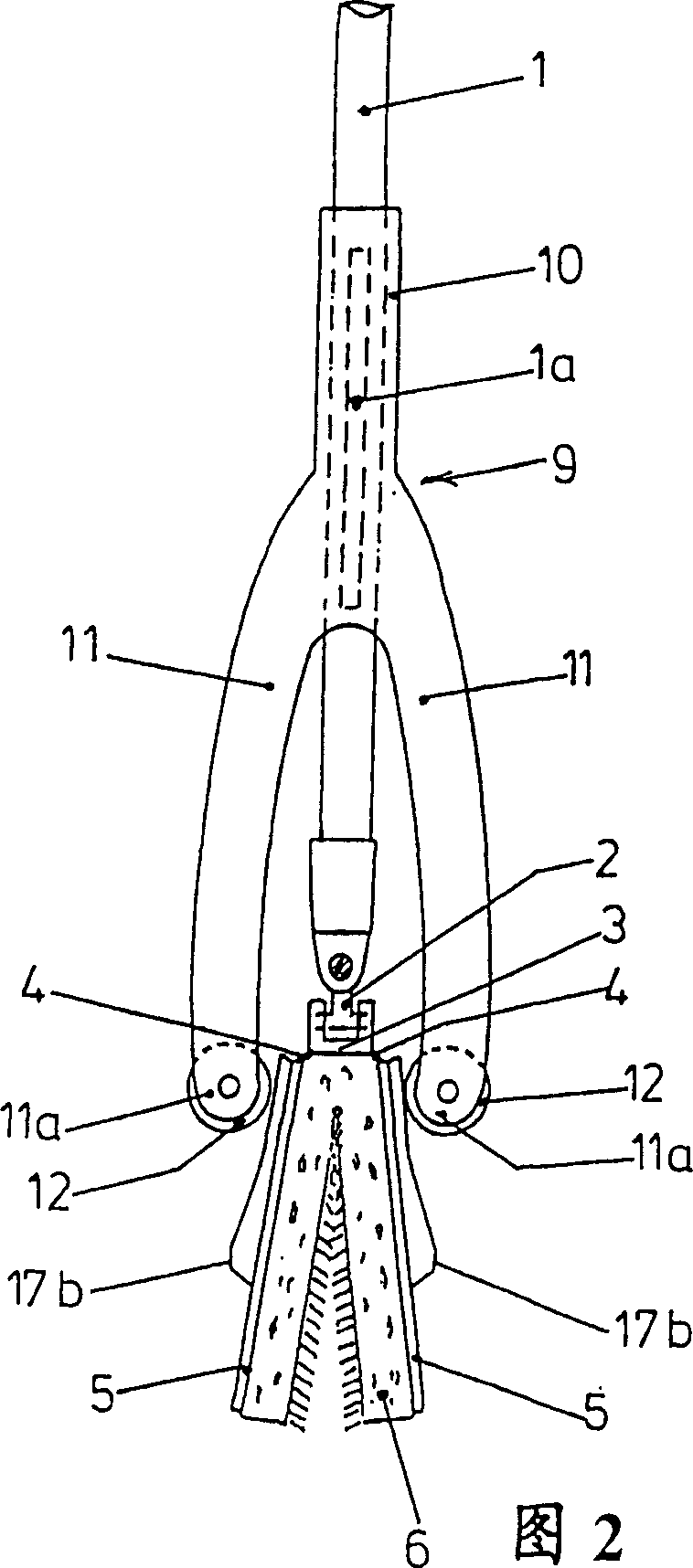

[0031] The mop shown in FIGS. 1 to 5 has a mop shaft 1 which is connected via a universal joint 2 to a support center part 3 in a non-rotatable but pivotable manner in all directions. The bracket central piece 3 is respectively connected with a mop wing-shaped bracket 5 through hinges 4 installed on both sides.

[0032] The two mop wing supports 5 and the support center piece 3 carry a water-absorbing, wringable wiper lining 6 which usually consists of a foam layer 7 and a fleece cover 8 .

[0033] The pressing slide 9 is displaceable along the mop rod 1 , and the pressing slide 9 has a guide sleeve 10 which is non-rotatably movable longitudinally on the mop stick 1 . For example, a longitudinal groove 10a is provided in the bore of the guide sleeve 10, in which the pin 1a mounted on the mop rod 1 engages.

[0034] The guide bush 10 is rigidly connected to two pressing arms 11, which in the exemplary embodiment shown in FIGS. 12.

[0035] In FIG. 6 it is shown that the roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com