Method for increasing creep rate of compacted graphite cast iron by electromagnetic field

A technology of vermicular graphite cast iron and electromagnetic field, which is applied in the field of increasing the creep rate of vermicular graphite cast iron by electromagnetic field, and can solve the problems of low creep rate and unstable creeping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

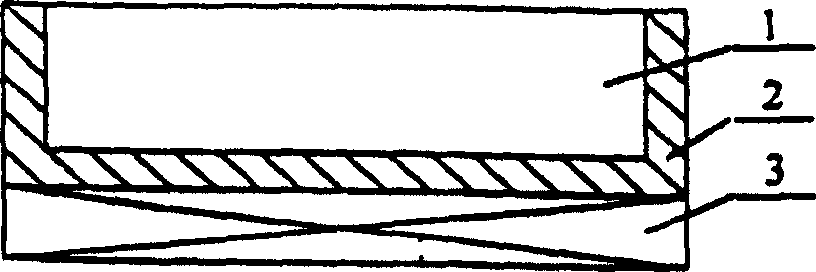

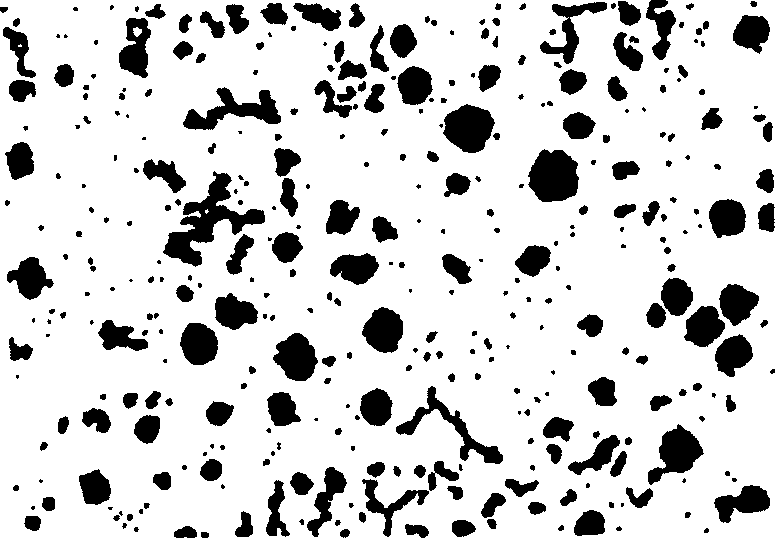

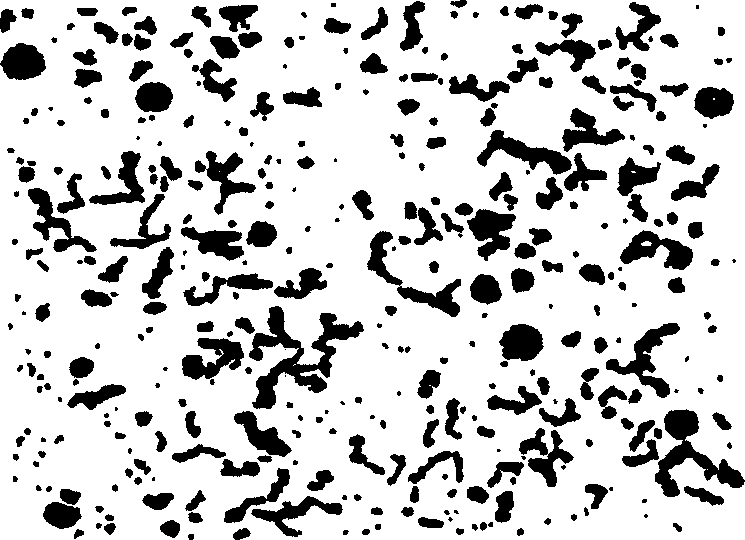

[0013] Below is the embodiment that the present invention selects the vermative agent to carry out vermative treatment to molten iron, and the temperature of its vermative treatment is 1420~1450 ℃, and power frequency is 50 Hz, and magnetic induction intensity is: 0.01~0.03T, wherein example 1, 3, 5, and 7 are the experimental parameters and results of the molten iron after creeping treatment without pulsed magnetic field; Examples 2, 4, 6, and 8 are the experimental parameters and results of the molten iron after creeping treatment with pulsed magnetic field.

[0014] The chemical composition (wt%) of molten iron used in Examples 1-8 is C: 3.4-3.8%, Si: 2.2-2.6%, Mn: 0.5-0.8%.

[0015] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com