Combined cylinder sleeve of opposed piston two-stroke engine

An opposed-piston, combined technology, used in internal combustion piston engines, combustion engines, engine components, etc., to minimize fluctuations in boundary conditions, accurate and reliable comparisons, and improve accuracy and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

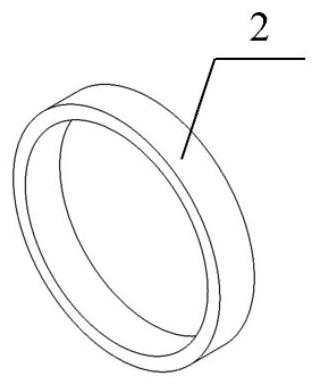

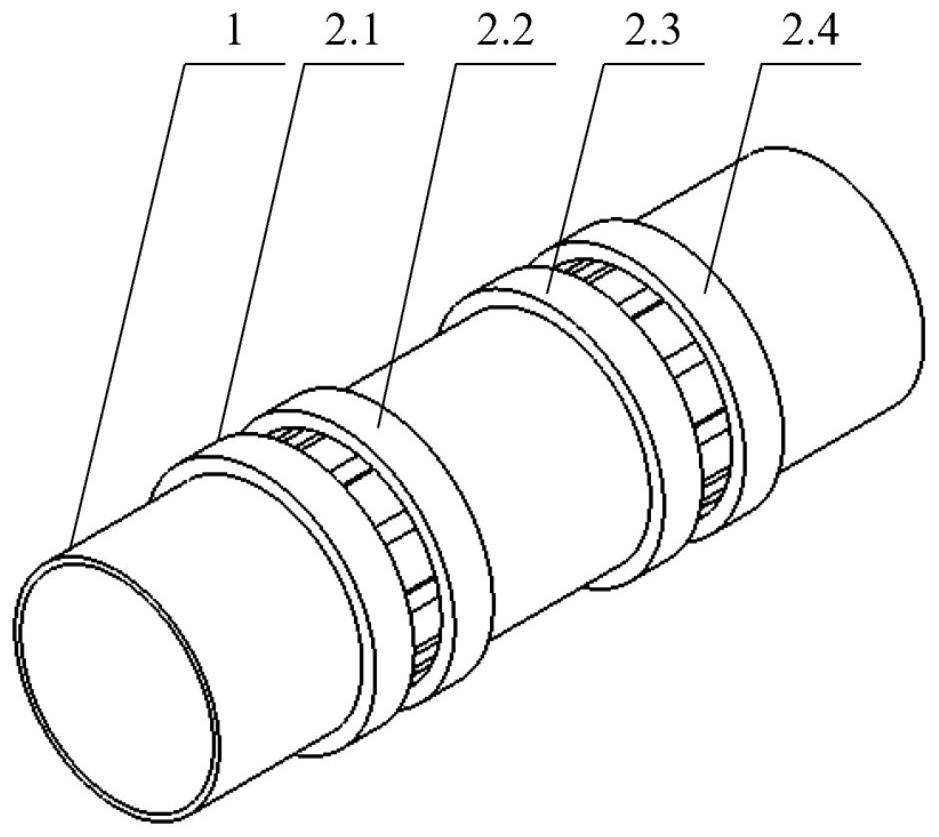

[0062] like image 3 As shown, a combined cylinder liner of an opposed-piston two-stroke engine disclosed in this embodiment includes a basic cylinder liner 1, a fully enclosed collar 2.1, a fully enclosed collar 2.2, a fully enclosed collar 2.3, and a fully enclosed collar 2.4 . Among them, the fully enclosed collar 2.1 and the fully enclosed collar 2.2 are installed on the air inlet of the basic cylinder liner, and the air flow enters the cylinder liner from the air inlet controlled by the fully enclosed collar 2.1 and the fully enclosed collar 2.2, and flows from the fully enclosed collar 2.2. The exhaust port composed of 2.3 and the fully closed collar 2.4 is discharged from the cylinder liner.

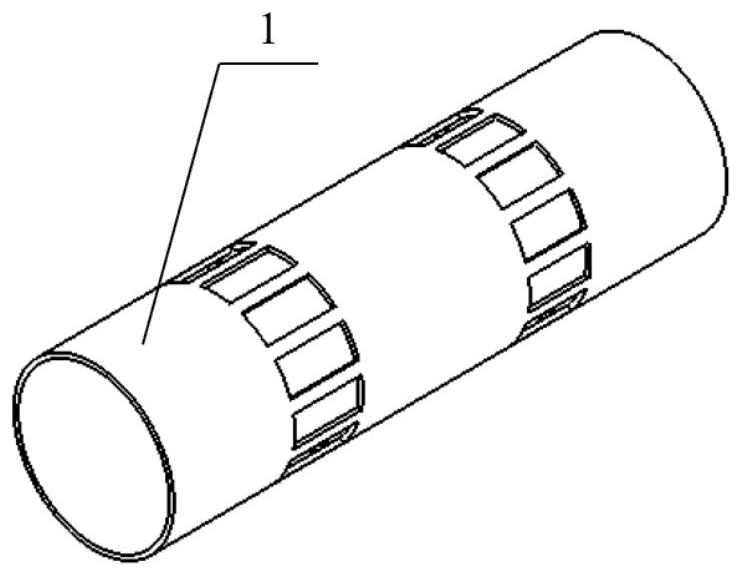

[0063] figure 1 It is the basic cylinder liner 1, and there are two circles of air ports on both sides, one side is the intake port, and the other side is the exhaust port. The height and width of the intake and exhaust ports of the basic cylinder liner 1 are the maximum allowab...

Embodiment 2

[0072] like Figure 8 As shown, a combined cylinder liner of an opposed-piston two-stroke engine disclosed in this embodiment includes a basic cylinder liner 1, a variable width ratio liner 3.1 mounted on the intake port of the basic cylinder liner, and an exhaust gas mounted on the basic cylinder liner. The mouth has a variable width ratio collar of 3.2.

[0073] Figure 7 In order to change the width ratio of the collar, it is directly installed on the basic cylinder liner. Figure 7 The port width of the variable width ratio collar 3 is equal to the port width of the basic cylinder liner 1 , and the port height of the variable width ratio collar 3 is smaller than that of the basic cylinder liner 1 .

[0074] Figure 9 For the exhaust port section at this time, in this installation position, the variable width ratio collar does not rotate in the circumferential direction, and the exhaust port width of the combined cylinder liner at this time is w01.

[0075] Figure 10 ...

Embodiment 3

[0083] like Figure 16 As shown, a combined cylinder liner of an opposed-piston two-stroke engine disclosed in this embodiment includes a basic cylinder liner 1, a fully closed collar 2.5, a fully closed collar 2.6 and a variable width ratio collar 3.3. Among them, the variable width ratio collar 3.3 is installed on the air inlet of the basic cylinder liner 1, and the fully enclosed collar 2.5 and the fully closed collar 2.6 are installed on the variable width ratio collar 3.3.

[0084] Figure 14 It is a variable width ratio collar of 3.3, and its port width and port height are consistent with the intake port of the basic cylinder liner.

[0085] Figure 15 It is shown that the variable width ratio collar 3.3 is installed on the intake port of the basic cylinder liner 1.

[0086] Figure 17 A relative installation position is described, the distance between the fully enclosed collar 2.5 and the fully enclosed collar 2.6 is L8, and the distance between the fully enclosed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com