Combustion structure and engine with same

A combustion structure and combustion chamber technology, which is applied to combustion engines, internal combustion piston engines, engine components, etc., can solve problems such as complex pre-combustion chamber structures, and achieve complex pre-combustion chamber structures, simplified structures, and improved scavenging efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

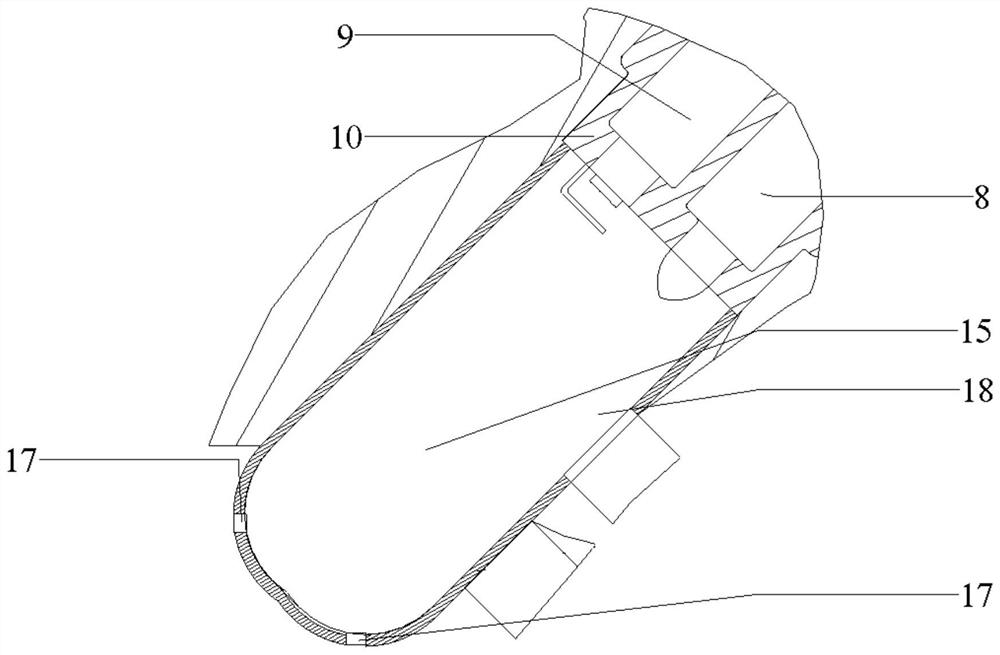

[0057] see Figure 8 , in this embodiment, the high-temperature mixed gas ignited in the pre-combustion chamber 15 can be injected into the combustion chamber 19 through the injection holes 17, there are two injection holes 17, and the two injection holes 17 are arranged at intervals along the first preset direction, In this way, the gas in the pre-chamber 15 can be uniformly injected into the combustion chamber 19 .

Embodiment 2

[0059] see Figure 9 , in this embodiment, the high-temperature mixed gas ignited in the pre-combustion chamber 15 can be injected into the combustion chamber 19 through the injection holes 17, and there are four injection holes 17, wherein the two injection holes 17 are spaced along the first preset direction The other two injection holes 17 are arranged at intervals along the second preset direction, so that the gas in the pre-combustion chamber 15 can be uniformly injected into the combustion chamber 19 .

Embodiment 3

[0061] see Figure 10 , in this embodiment, the high-temperature mixed gas ignited in the pre-combustion chamber 15 can be injected into the combustion chamber 19 through the injection holes 17, there are three injection holes 17, and the two injection holes 17 are arranged at intervals along the first preset direction, The third injection hole 17 is located between the other two injection holes 17 , so that the resistance of the gas in the pre-combustion chamber 15 to be injected into the combustion chamber 19 can be reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com