Steel rail probe development test method and test platform

A test method and a test platform technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to judge the state of the probe wheel probe, long development cycle of the probe wheel, and high time cost, so as to improve the utilization rate and reduce defective products efficiency and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Further description will be given below in conjunction with the accompanying drawings and the preferred embodiments of the present invention.

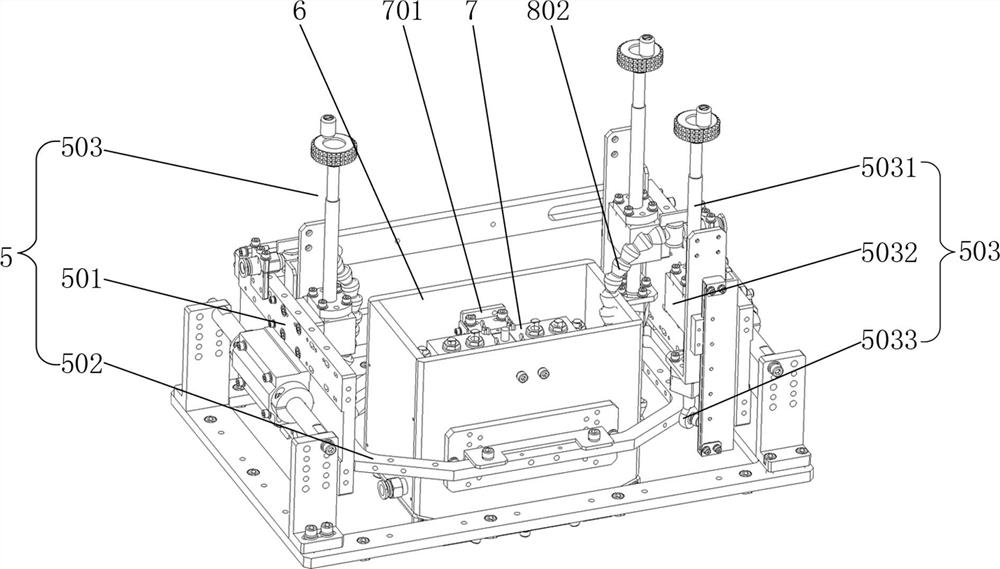

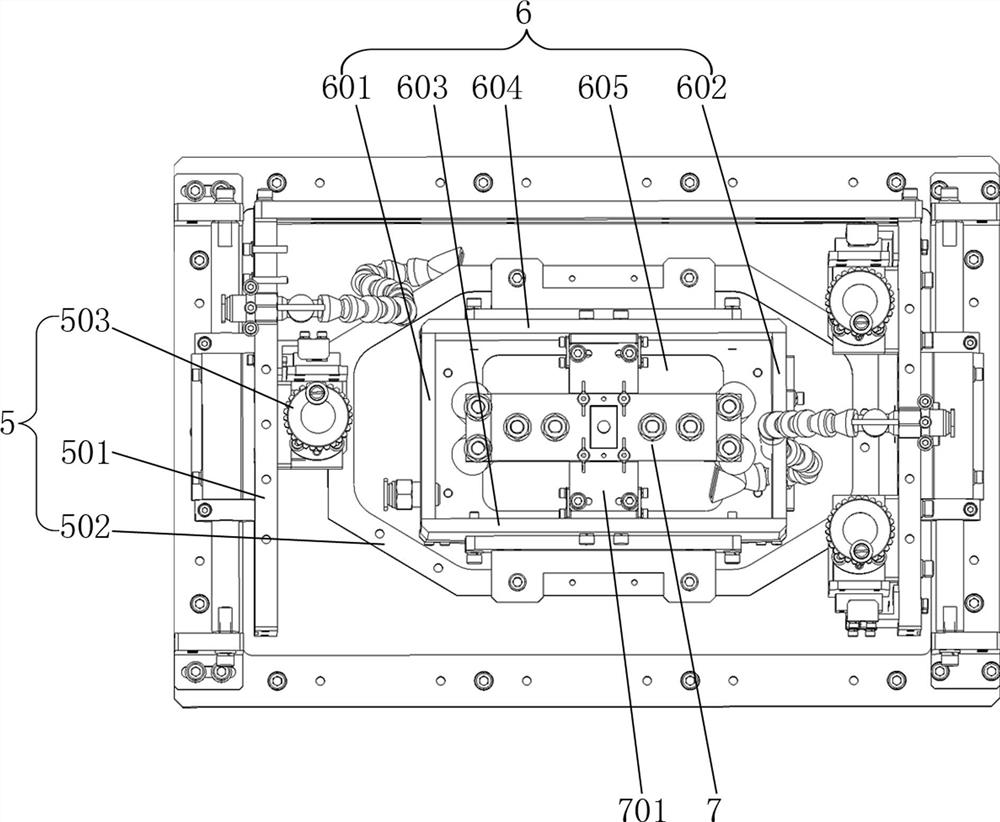

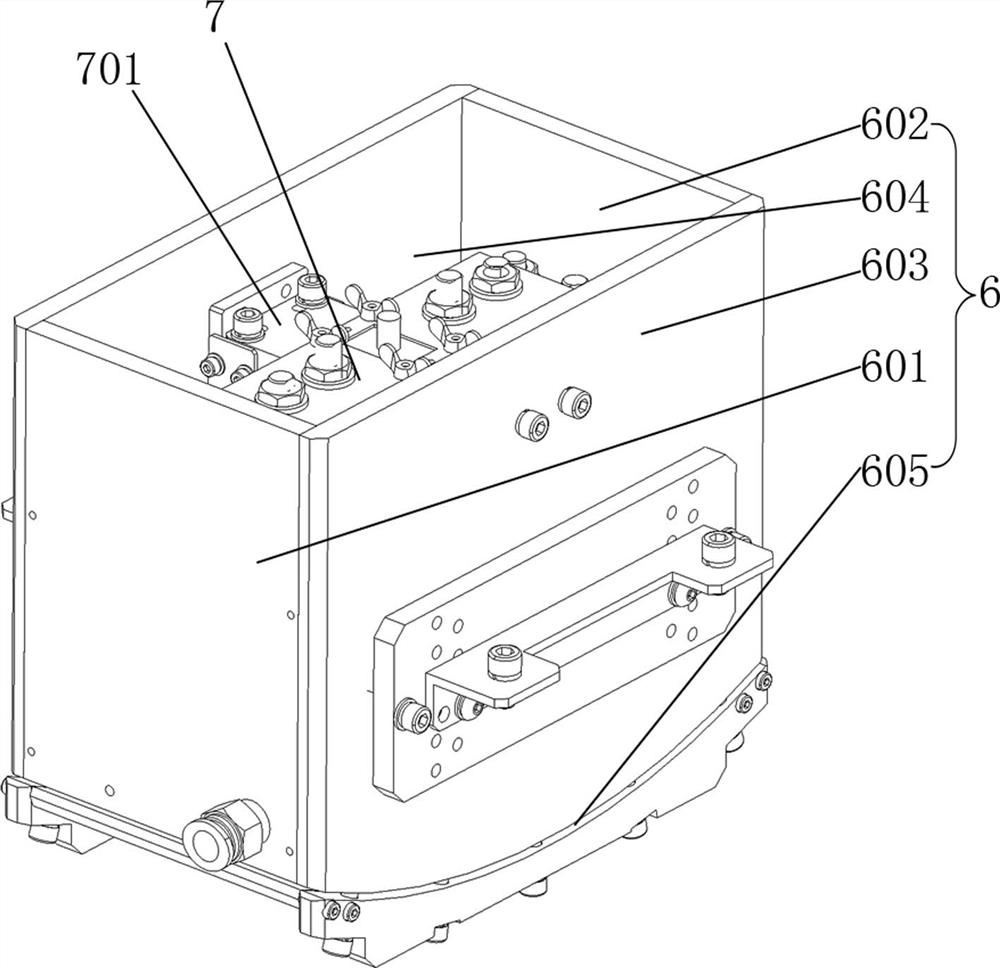

[0044] like figure 1 As shown, a rail probe development and test platform includes a rack 1, a test rail 2, two translation guide rails 3, a translation base 4, a tilt adjustment device 5, an open water tank 6, a probe mounting frame 7 and a coupling fluid circulation mechanism 8 ; The test rail 2 and the two translation guide rails 3 are arranged in parallel on the frame 1, and the test rail 2 is between the two translation guide rails 3; In this embodiment, the translation seat 4 is slidably installed through four sliders 401 On the translation guide rails 3 , each translation guide rail 3 corresponds to two sliding blocks 401 , and the translation base 4 is moved by manually pushing the translation bases 4 .

[0045] like Figure 1 to Figure 3 As shown, the tilt adjustment device 5 is installed on the translation base 4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com