Manufacturing and assembling equipment for LED lighting lamp

A technology for LED lighting and assembly equipment, which is applied to lighting devices, manufacturing tools, metal processing equipment, etc., and can solve problems such as inapplicability, inapplicability of LED lights, and inability to smoothly connect the threaded port and the threaded port of the lampshade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described below with reference to the accompanying drawings. During this process, in order to ensure the clarity and convenience of the description, we may exaggerate the width of the lines or the size of the components in the illustrations.

[0032] In addition, the following terms are defined based on the functions in the present invention, and may vary according to the user's intention or convention. Therefore, these terms are defined based on the entire content of this specification.

[0033]The assembly and processing objects in this embodiment are the lampshade body and the lamp holder body. For details, please refer to Figure 7 shown.

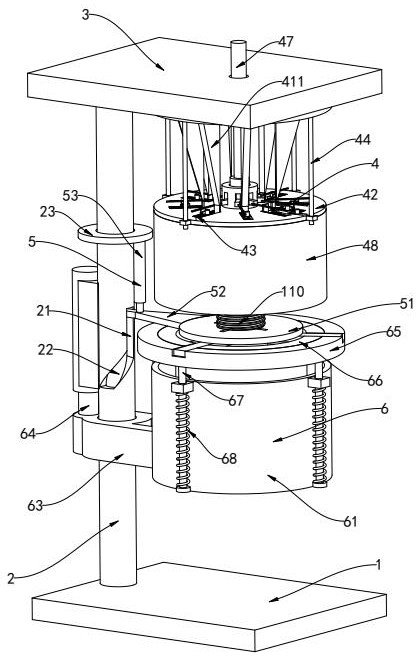

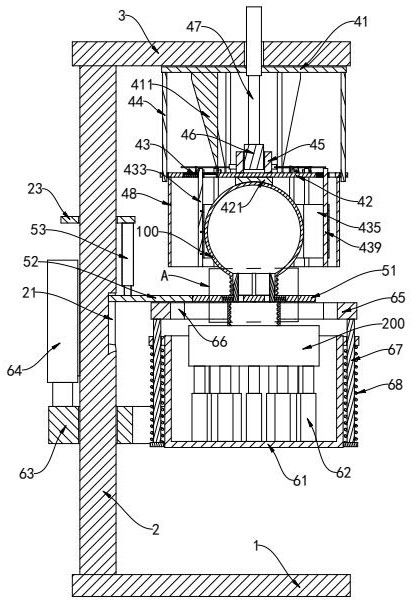

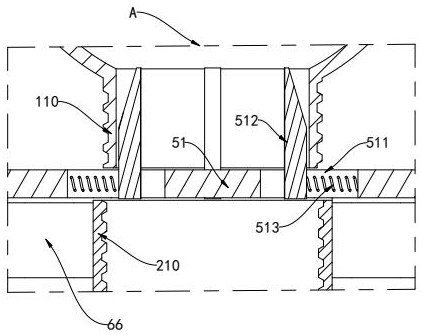

[0034] see figure 1 and figure 2 , an LED lighting fixture manufacturing and assembling equipment, comprising an assembly substrate 1, an assembly column 2 and an assembly top plate 3, the assembly column 2 is placed vertically, and the assembly top plate 3 and the assembly substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com