Electric translation type sprinkling machine powered by generator set

A generator set, translational technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of fragile cost, small adaptability of sprinklers, complex structure of water turbine drive transmission, etc., to facilitate cleaning and replacement. , the effect of preventing blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

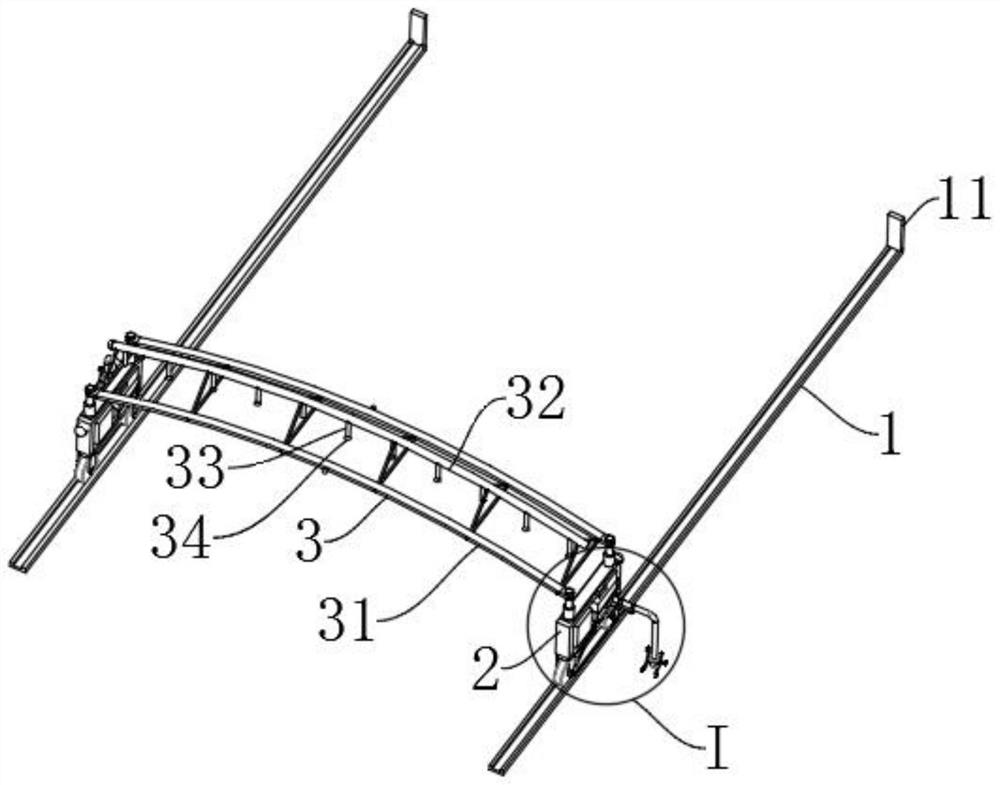

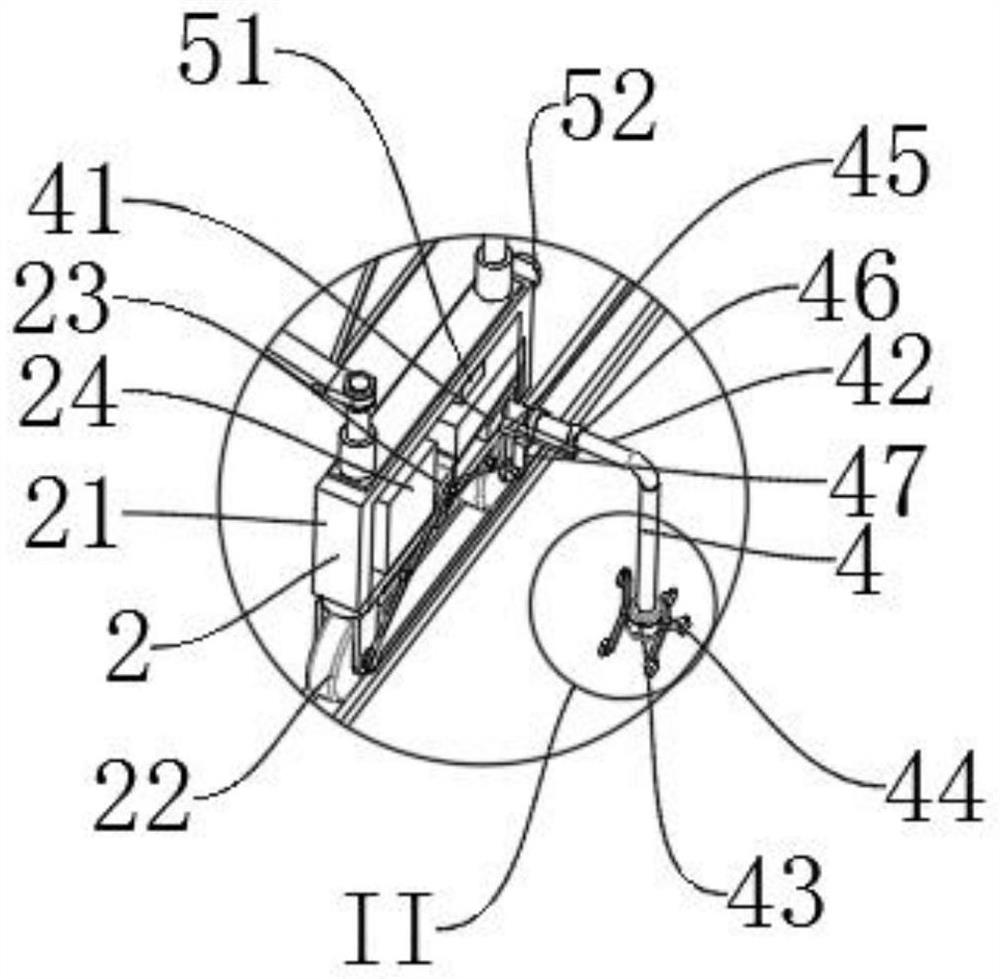

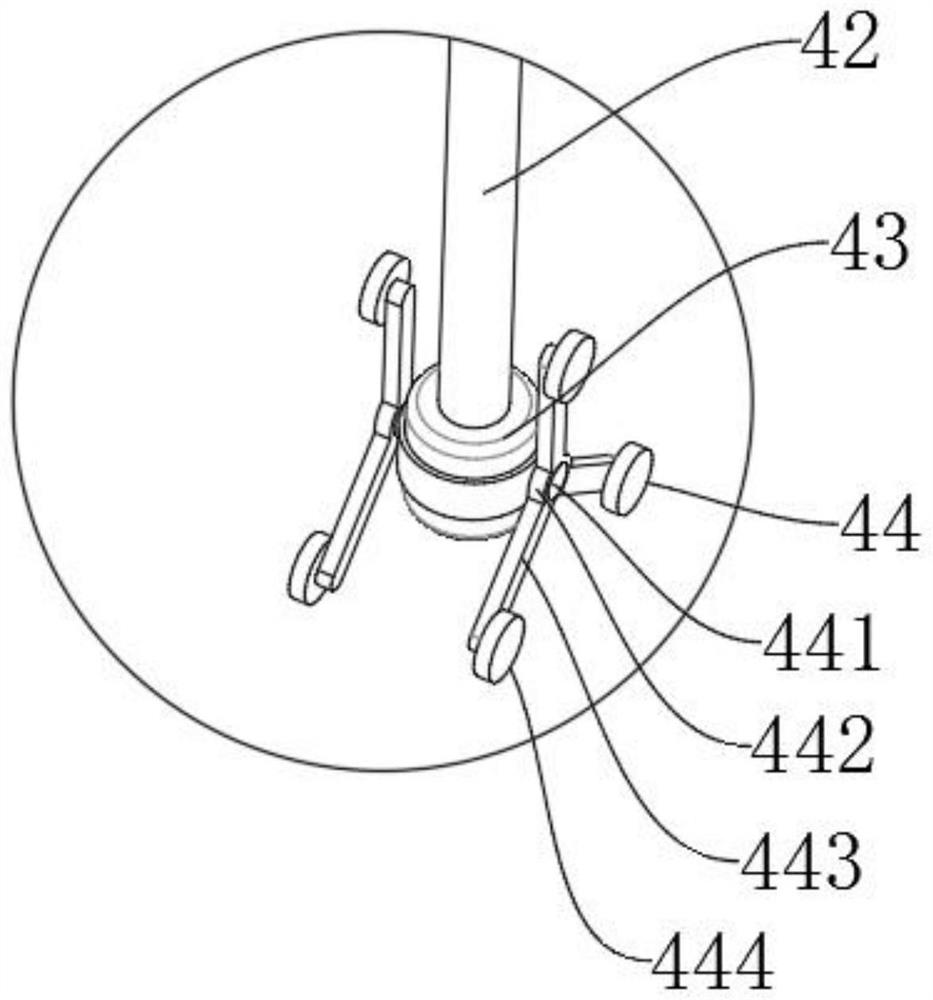

[0038] Example one, as Figure 1-6 As shown in the figure, an electric translational sprinkler powered by a generator set includes a track 1, a traveling mechanism 2, and a sprinkler mechanism 3. The track 1 is provided with two parallel and spaced apart, and each track 1 is provided with a Walking mechanism 2, a sprinkler irrigation mechanism 3 for sprinkling the farmland is arranged between the two walking mechanisms 2, and the walking mechanism 2 is also provided with a water supply mechanism 4 for supplying water to the sprinkler irrigation mechanism 3. This arrangement is due to the use of two rails 1 and its associated water supply mechanism 4. The matching traveling mechanism 2 can ensure that the traveling mechanism 2 can travel along the preset trajectory, thereby realizing the function of automatic sprinkler irrigation;

[0039] The traveling mechanism 2 includes a mounting frame 21. The bottom of the mounting frame 21 is provided with two traveling wheels 22 at inte...

Embodiment 2

[0043] Embodiment 2, on the basis of Embodiment 1, as Figure 5-6 As shown, the driving structure 23 includes a driving motor 231 and a belt 232. The driving motor 231 is mounted on the mounting frame 21, and the output shaft of the driving motor 231 and the axles of the two traveling wheels 22 are distributed in an isosceles triangle, and the output of the driving motor 231 is distributed in an isosceles triangle. A belt 232 is used to drive the connection between the shaft and the axles of the two traveling wheels 22;

[0044] The driving structure 23 also includes a tensioning assembly 233 for ensuring that the belt 232 is in a tensioned state;

[0045] In this way, the belt 232 can be driven to rotate by the driving motor 231, and the belt 232 can drive the two traveling wheels 22 to roll, thereby realizing the function of driving the traveling mechanism 2 to travel.

Embodiment 3

[0046] Embodiment 3, on the basis of Embodiment 1, as Image 6 As shown, the tensioning assembly 233 includes a sliding rail 2331 and a sliding block 2332. The sliding rail 2331 is arranged along the length direction of the corresponding rail 1, and the sliding rail 2331 is slidably fitted with two sliding blocks 2332 along its length direction. There is a tensioning wheel 2333 that can roll with the belt 232, and the two tensioning wheels 2333 are located on both sides of the belt 232 respectively;

[0047] The tensioning assembly 233 further includes a driving member 2334 capable of driving the tensioning pulley 2333 to squeeze the belt 232;

[0048] In this way, the two tensioning pulleys 2333 can be driven by the driving member 2334 to squeeze the belt 232, so that the belt 232 is in a certain degree of tension, and the transmission effect between the driving motor 231 and the traveling wheel 22 is ensured. There are two, and they are located on both sides of the tensioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com