Shear type clamp

A clamp and scissor technology, which is used in the field of pipeline connection and fixation, can solve the problems of poor connection and fixation effect of cable ties, low stability, short service life, etc., and achieves convenient and quick installation and disassembly, no damage to the pipeline surface, and stable structure. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

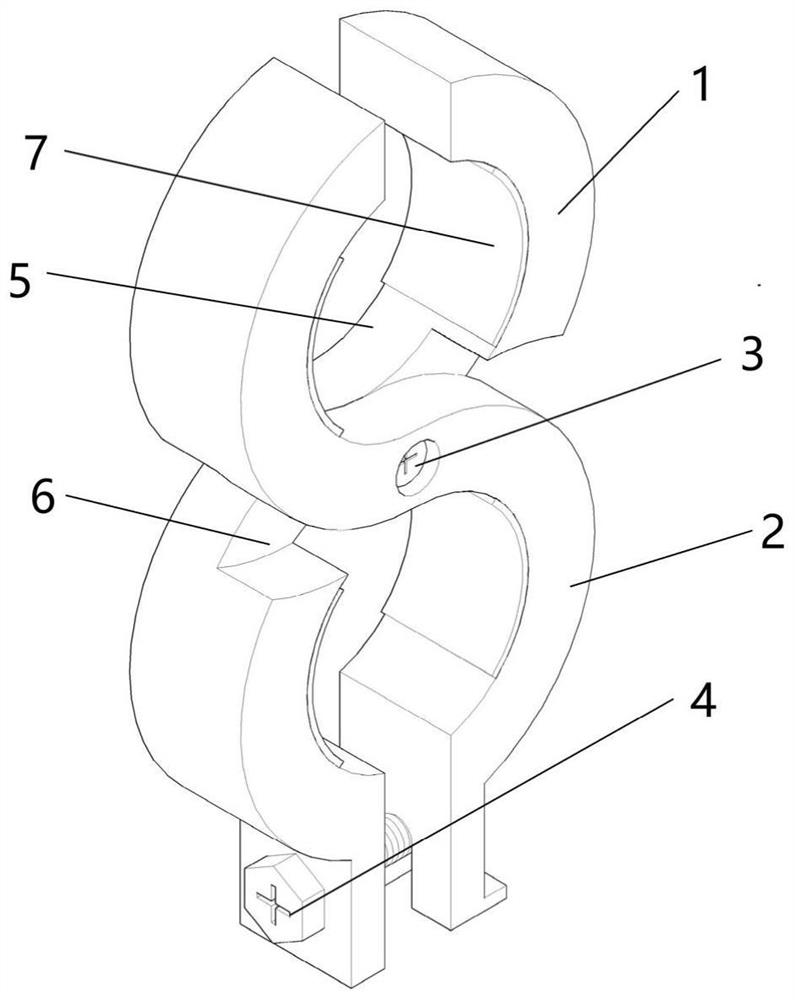

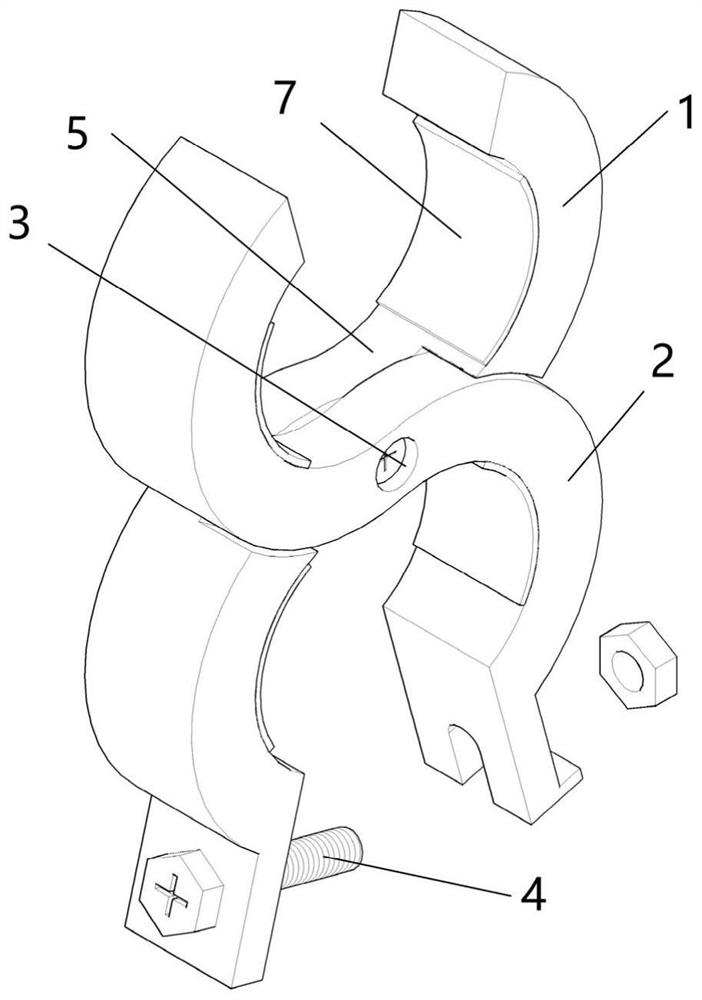

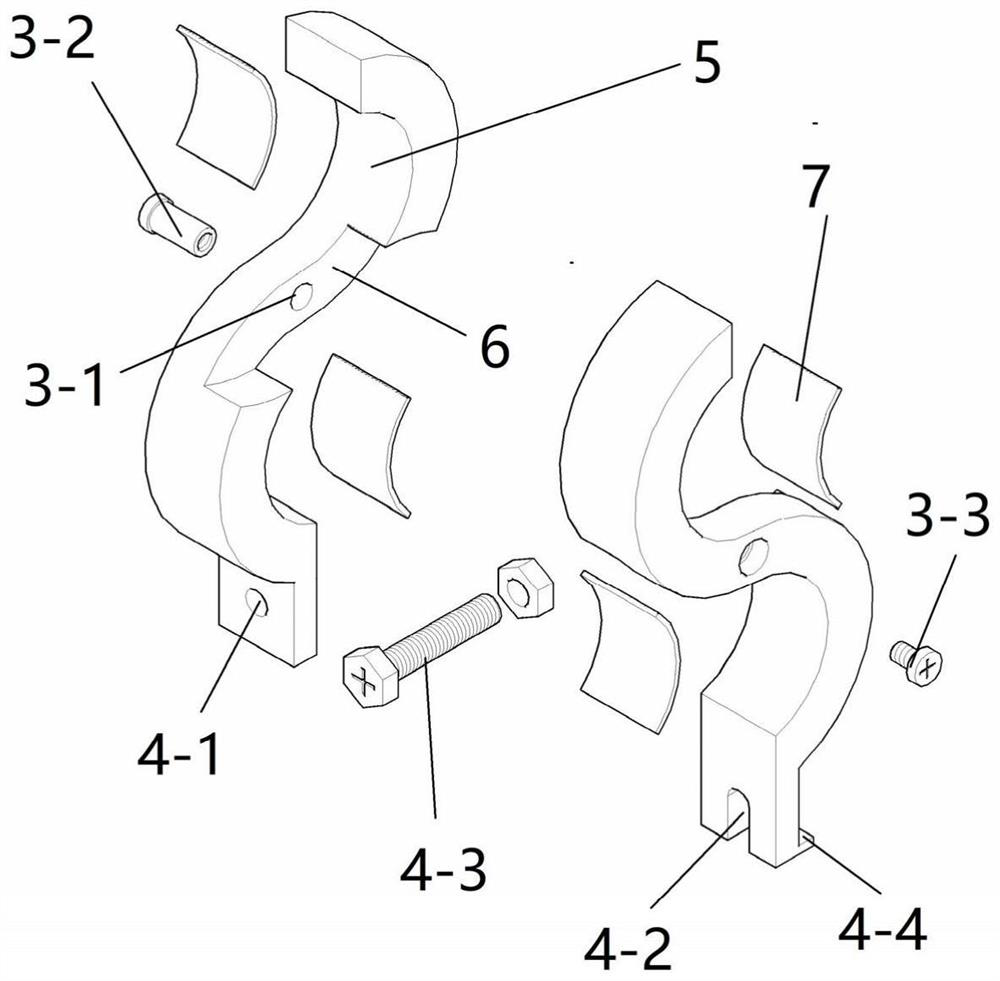

[0028] refer to Figure 1 to Figure 7 As shown, a scissor clamp provided by the present invention includes a first hoop handle 1, a second hoop handle 2, a hinged portion 3, and a fixed portion 4. The first hoop handle and the second hoop handle are provided with two Arc-shaped surface 5; in the embodiment in the figure, the first hoop handle and the second hoop handle are both composed of two semicircular rings welded end to end. When the first hoop handle and the second hoop handle are combined, the arc surfaces of the first hoop handle and the second hoop handle form two annular structures; A hinge part and a fixed part are arranged at any one or two positions between the annular structures, and at most one annular structure is arranged between the hinge part and the fixed part. Put different sizes of wire tubes inside the annular structure compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com