Production process of bionic tropical fishtail type skirt

A production process, fish tail technology, applied in the cutting of textile materials, textile and papermaking, dyeing methods, etc., can solve problems such as fabric and dye waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

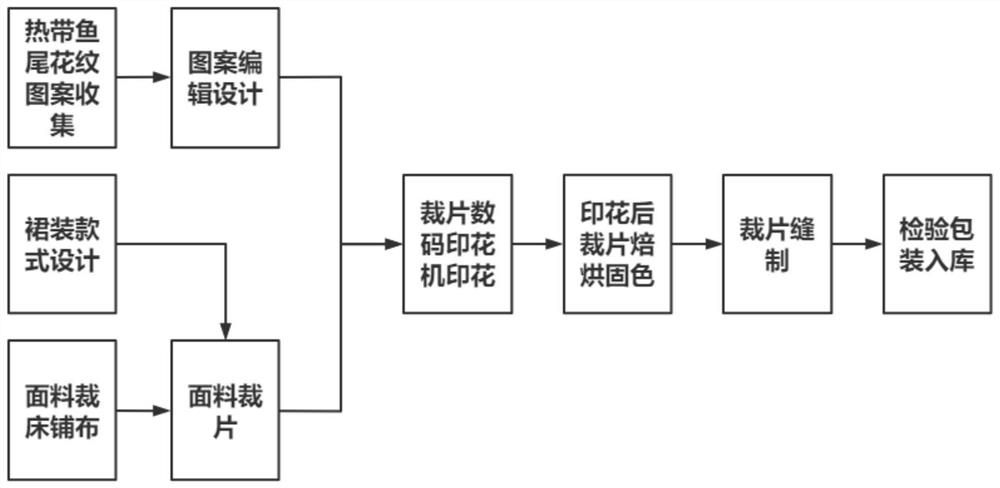

[0025] according to figure 1 As shown in the figure, the production process of the bionic tropical fishtail style skirt includes: collection of tropical fishtail patterns—pattern editing and design—dress style design—fabric cuttings—digital printing machine printing for cuttings— - After printing, the pieces are baked and fixed - the pieces are sewn - the inspection and packaging are put into storage.

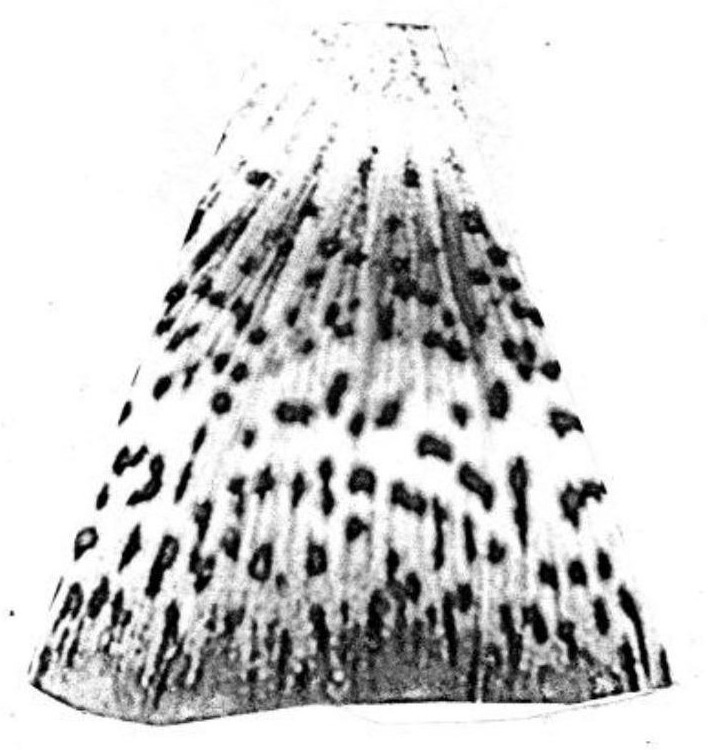

[0026] The selected fabric composition is 70 lyocell / 30 cotton, and the fabric structure is 2 / 1. figure 2 The part of the tropical fish tail shown is an inspiration pattern. After editing and designing with Photoshop CS6, it is imported into the digital printing machine DReAM digital inkjet printing machine, and digital inkjet printing is carried out on the skirt pieces using reactive dyes, and then the finished pieces are printed. The color is fixed in the baking system of Reggiani DReAM, and the pattern is sewn after the color is fixed, and the effect is as follows image ...

Embodiment 2

[0028] according to figure 1 As shown in the figure, the production process of the bionic tropical fishtail style skirt includes: collection of tropical fishtail patterns—pattern editing and design—dress style design—fabric cuttings—digital printing machine printing for cuttings— - After printing, the pieces are baked and fixed - the pieces are sewn - the inspection and packaging are put into storage.

[0029] The selected fabric composition is 70 lyocell / 30 cotton, and the fabric structure is 2 / 1. Figure 4 The part of the tropical fish tail shown is an inspiration pattern. After editing and designing with Photoshop CS6, it is imported into the digital printing machine DReAM digital inkjet printing machine, and digital inkjet printing is carried out on the skirt pieces using reactive dyes, and then the finished pieces are printed. The color is fixed in the baking system of Reggiani DReAM, and the pattern is sewn after the color is fixed, and the effect is as follows Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com