Bottle blowing machine control system and bottle blowing machine

A control system and blow molding machine technology, applied in the direction of comprehensive factory control, etc., can solve the problems of messy wiring, maintenance and line finding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

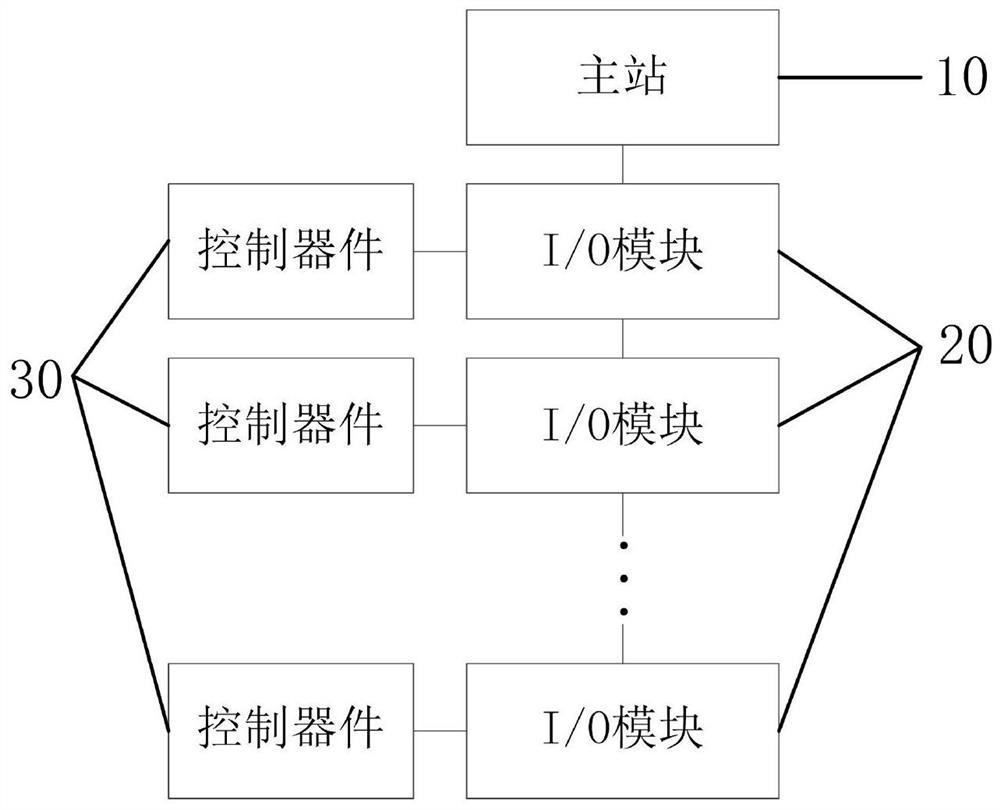

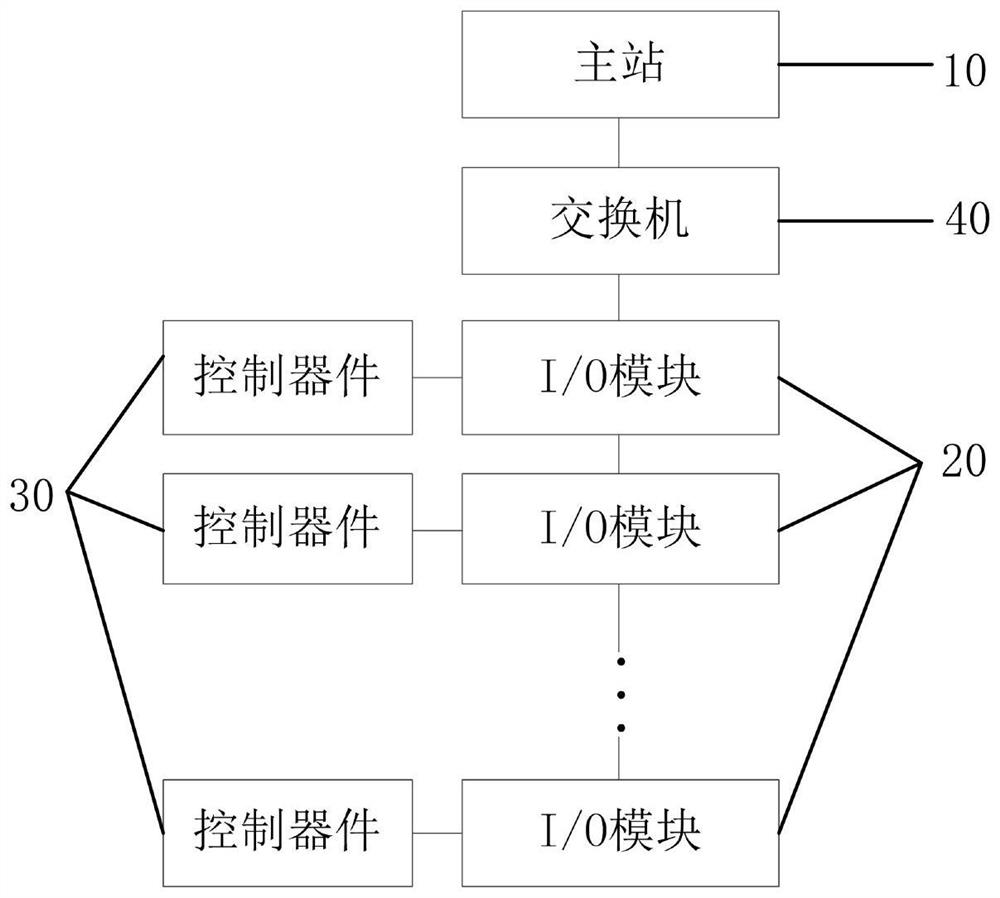

[0034] figure 1 This is a structural block diagram of a bottle blowing machine control system provided in Embodiment 1 of the present invention. The bottle blowing machine control system of this embodiment can be applied to a bottle blowing machine provided with multiple mold bases, which reduces the number of mold bases on the bottle blowing machine. On the basis of the connection with the master station, the process parameters of each mold base are controlled.

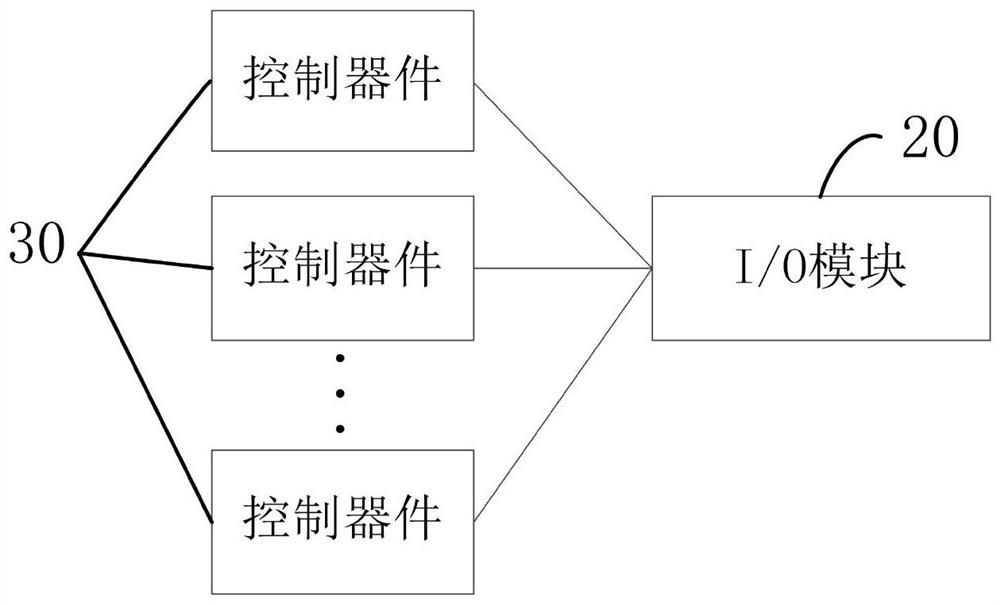

[0035] like figure 1 As shown, the bottle blowing machine control system of the embodiment of the present invention includes a master station 10, an I / O module 20 arranged on each mold base as a slave station, and on each mold base, the control device 30 is connected to the I / O The modules 20 are connected, and the I / O modules 20 on each mold frame are connected in sequence and then connected to the master station 10 .

[0036] The I / O modules 20 can include discrete, analog, and special modules of various types. T...

Embodiment 2

[0055] Figure 4 It is a schematic structural diagram of a bottle blowing machine provided in the second embodiment of the present invention. The bottle blowing machine is provided with at least one mold frame 50, and each mold frame 50 is provided with at least one control device 30. The bottle blowing machine also includes the first embodiment. The blow molding machine control system. The bottle blowing machine control system includes a master station 10 and an I / O module 20 arranged on each mold base 50 as a slave station. On each mold base 50, the control device 30 is connected to the I / O module 20, and each mold base 50 is connected to the I / O module 20. The I / O modules 20 on the 50 are connected in sequence and then connected to the master station 10. The master station 10 is used to communicate with the control device 30 on the mold base 50 through the I / O modules 20 on each mold base 50 to control the control device. 30 Perform the blowing action.

[0056] The bottle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com