Double-servo feeding device for feeder and feeding method of double-servo feeding device

A technology of feeding device and double servo is applied in the field of double servo feeding device for feeder, which can solve the problems of low practicability, low applicability, inability to adjust the height of the feeder, etc., and achieves the effect of high practicability and high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

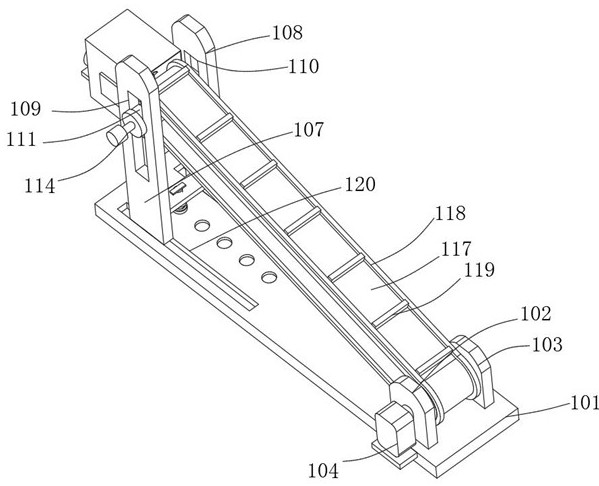

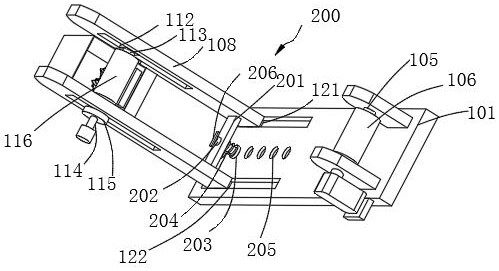

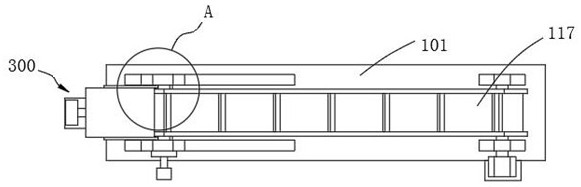

[0055] see Figure 1-3 , The present invention provides a technical solution: a dual-servo feeding device for a feeder, comprising a bottom plate 101, a first connecting plate 102 and a second connecting plate 103 are symmetrically and fixedly connected on the upper surface of the bottom plate 101; A servo motor 104, the output end of the first servo motor 104 is fixedly connected with a first driving rod 105 that movably penetrates the first connecting plate 102 and is rotatably connected to the inner wall of the second connecting plate 103; The roller 106, the driving roller 106 is placed between the first connecting plate 102 and the second connecting plate 103; two chutes 120 are opened on the upper surface of the bottom plate 101, and the first sliding block 122 and the second sliding groove 120 are respectively installed in the two chutes 120. Two sliding blocks 121; the upper surface of the first sliding block 122 is fixedly connected with a third connecting plate 107, ...

Embodiment 2

[0060] see Figure 1-6 , The present invention provides a technical solution: a double-servo feeding device for a feeder, a crushing mechanism 300 is provided on the third sliding block 111 and the fourth sliding block 112, and the crushing mechanism 300 includes two connecting bars 301, two The connecting bars 301 are respectively fixedly connected to the opposite ends of the third sliding block 111 and the fourth sliding block 112 respectively; the ends of the two connecting bars 301 corresponding to the ends away from the third sliding block 111 and the fourth sliding block 112 are respectively fixedly connected with a clamp. The plate 302 is located at the opposite end of the two clamping plates 302 and is fixedly connected with a blocking frame 303. The transmission belt 117 is located in the blocking frame 303, and is fixedly connected to the outer wall of the blocking frame 303. A connecting seat 304 is installed on the upper surface of the connecting seat 304. The seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com