Full-automatic loading and unloading system for reverse osmosis membrane

A loading and unloading system, reverse osmosis membrane technology, applied in general water supply saving, manufacturing tools, hand-held tools, etc., can solve the problems of large size and weight of membrane elements, low efficiency of membrane elements, decreased loading and unloading efficiency, etc., achieving a high degree of automation, The effect of labor-saving operation and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

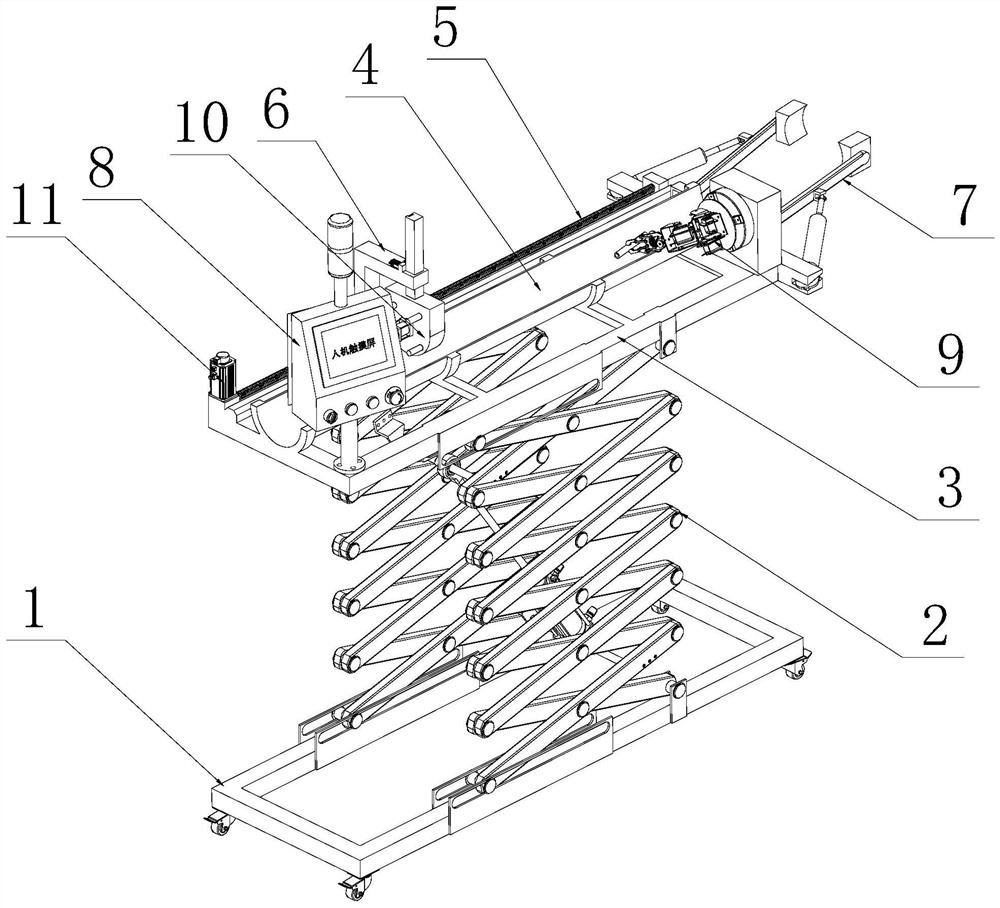

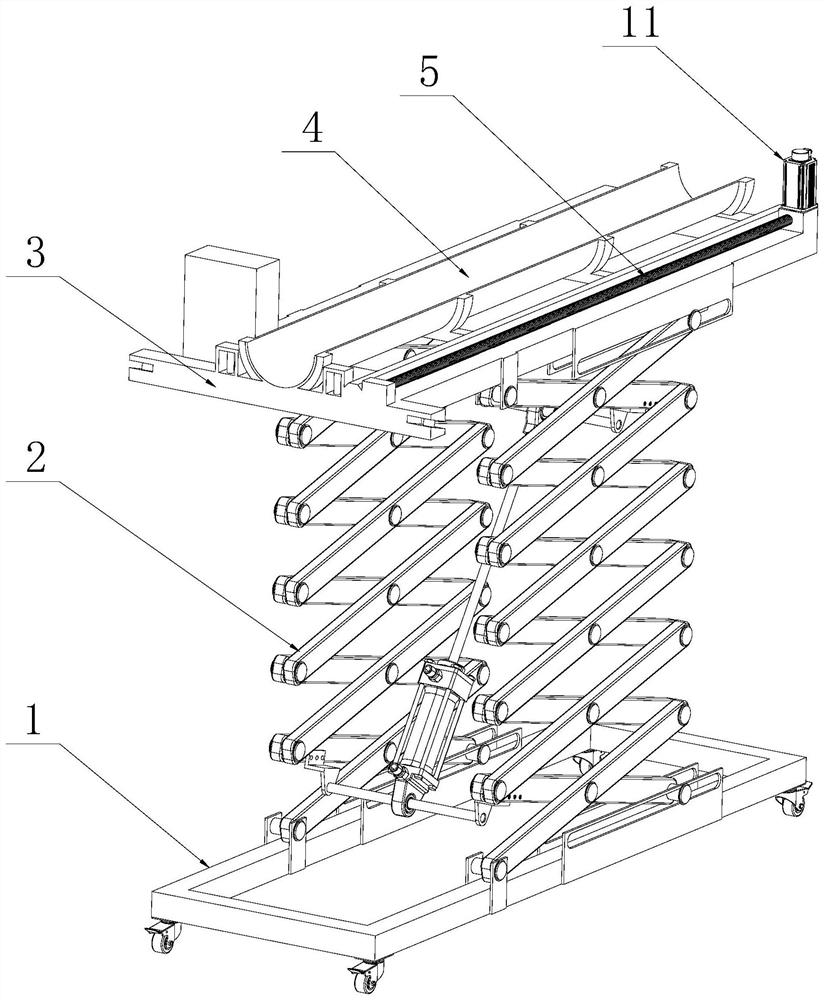

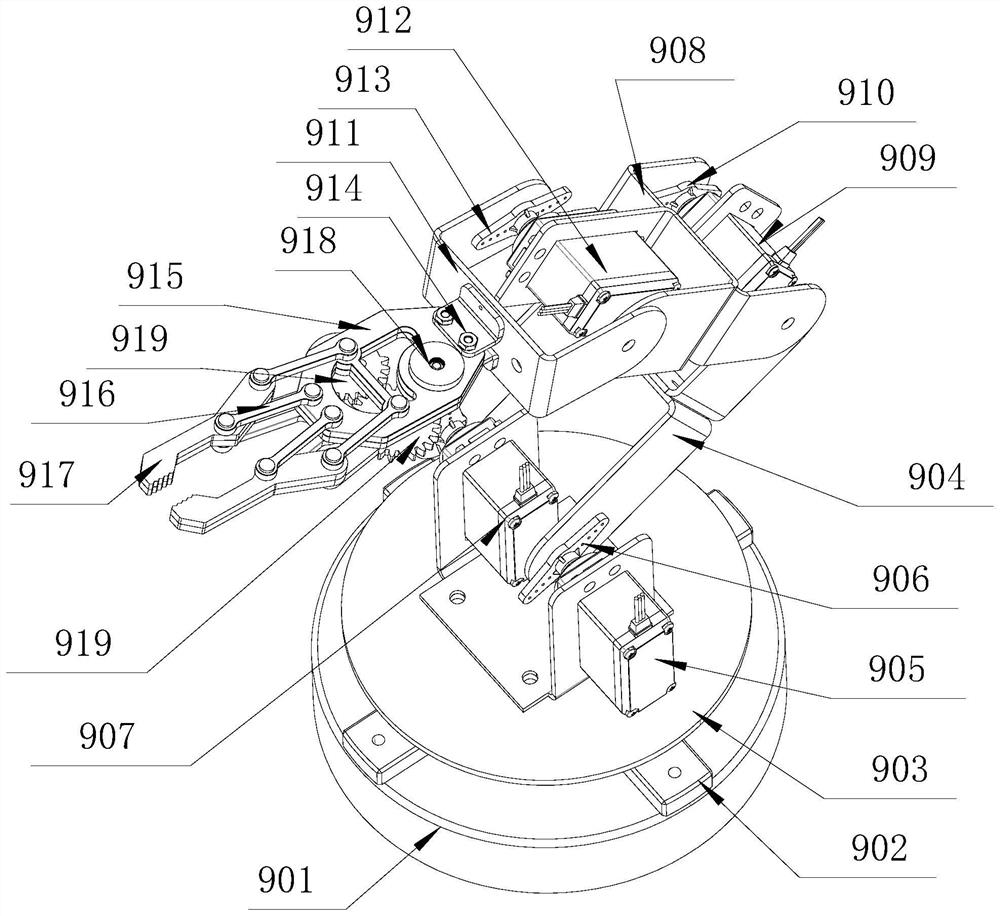

[0031] like Figures 1 to 7 , this embodiment provides a reverse osmosis membrane automatic loading and unloading system, including a base 1, a lifting bracket 2 is arranged on the base 1, a dismounting table is arranged on the lifting bracket 2, and the dismounting table includes a lifting bracket and a lifting bracket. 2. The connected mounting frame 3, the mounting frame 3 is provided with a membrane element placement slot 4, one end of the membrane element placement slot 4 is provided with a fixing clip 7, and the front side of the membrane element placement slot 4 is provided with a man-machine operation controller 8 and a manipulator 9. The rear side of the component placement slot 4 is provided with a drive screw 5, which is driven to rotate by the deceleration motor 11 provided on the mounting frame 3, and an "L"-shaped walking bracket 6 is threaded on the drive screw 5. The walking bracket The membrane element 6 is provided with a membrane loading and unloading mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com