Pumping system, pumping machine and cleaning method

A pumping system and pumping technology, applied in mechanical equipment, liquid displacement machinery, and parts of pumping devices for elastic fluids, etc., can solve the damage of pumping equipment parts, wear of delivery cylinders, and failure to replace them in time cleaning water etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

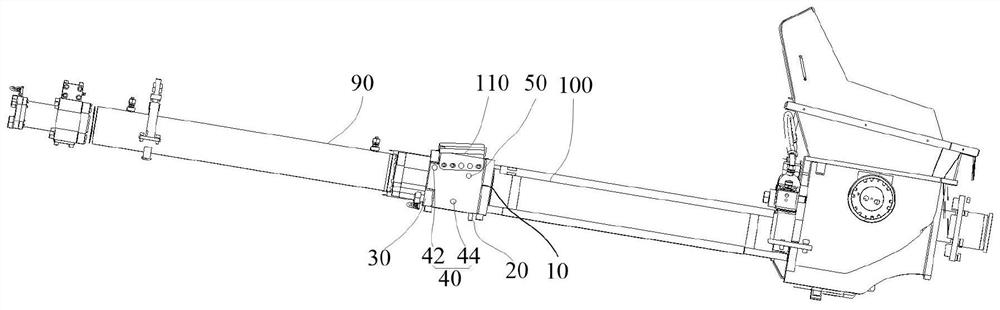

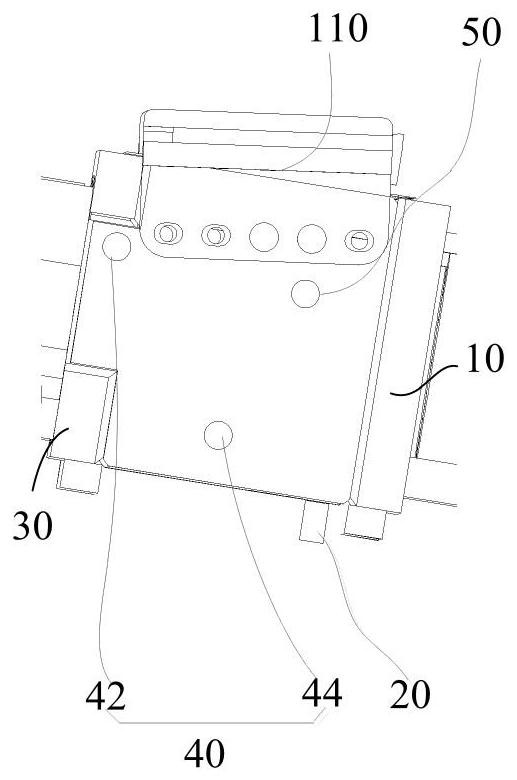

[0048] Specifically, as figure 1 As shown, in the first embodiment of the present invention, the drain valve 20 and the water injection valve 30 are electric valves. superior.

[0049] In the above setting, the drain valve 20 is located at the bottom of the washing chamber 10, which is convenient for the drain valve 20 to drain the washing water in the washing chamber 10, and the water injection valve 30 is located at the bottom of the washing chamber 10, which is convenient for the water injection valve 30 to fill the washing chamber 10. Therefore, it is ensured that the pumping system 110 can completely discharge the unsatisfactory washing water from the washing chamber 10 and refill the washing chamber 10 with clean washing water. This ensures that the on-site pumping equipment can work normally and the on-site pumping operation can be carried out smoothly.

[0050] Specifically, as figure 1 As shown, in the first embodiment of the present invention, the pumping system 1...

Embodiment 2

[0083] The second embodiment and the embodiment have the following differences:

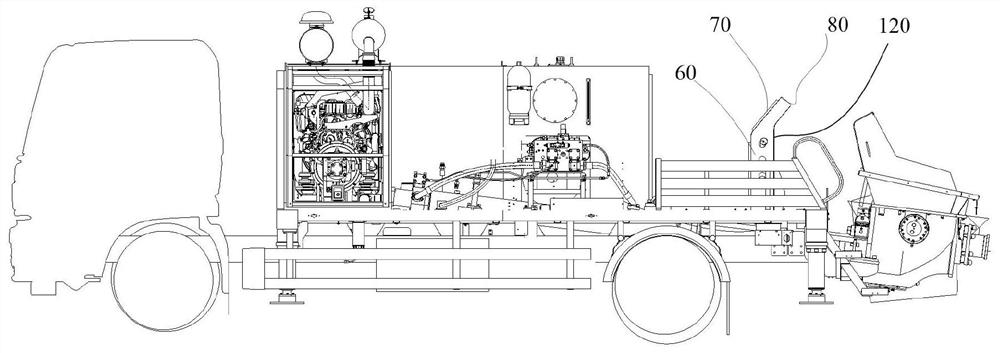

[0084] Specifically, as Figure 5 to Figure 8 As shown, in the second embodiment of the present invention, no water quality monitoring device 50 or particulate matter monitoring device is required, and the control component 60 does not have the function of judging whether the particle content of the washing water in the washing chamber 10 exceeds the standard.

[0085] Specifically, as Figure 8 As shown, in the second embodiment of the present invention, the control component 60 has a timing function. When the washing water in the washing room 10 is placed for a preset time, the control component 60 sends an alarm message to the display 80 .

[0086] Specifically, as Figure 8 As shown, in the second embodiment of the present invention, before step S70, the cleaning method further includes:

[0087] Step S11: The control component judges whether the washing water in the washing room exceeds t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com