Tractor front wheel speedup steering device and steering system

A steering device, tractor technology, applied in the field of tractors, can solve problems such as non-applicability, increased turning radius, and land destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

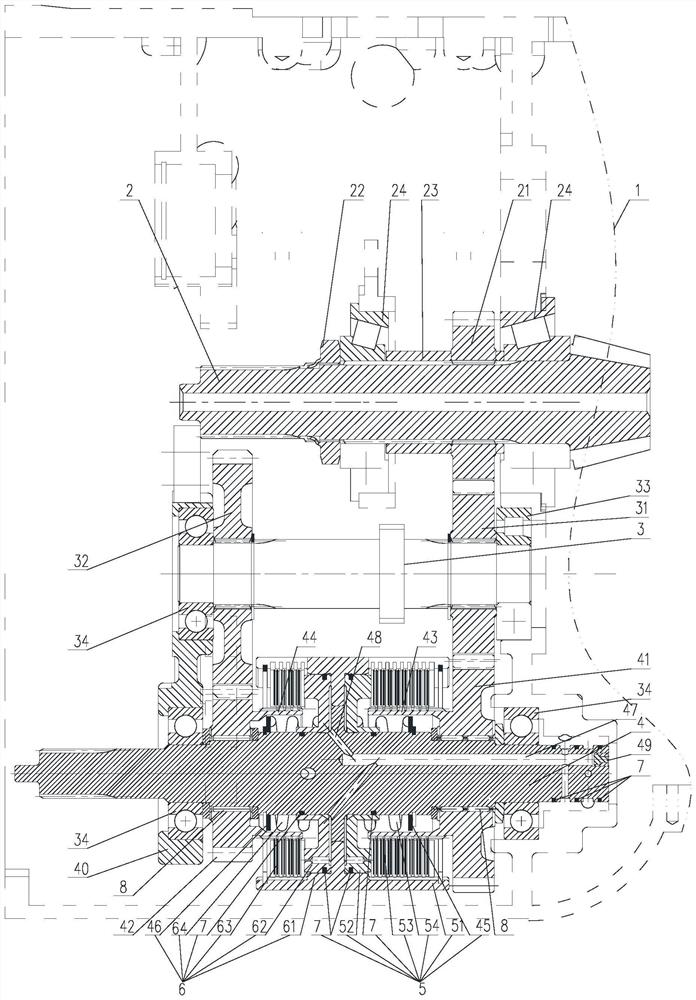

[0038] like figure 1As shown, a tractor front wheel speed-increasing steering device in this embodiment includes a rear axle housing 1, an input shaft 2, an idler shaft 3 and a transfer case output shaft 4. The input shaft 2, the idler shaft 3 and the splitter The transmission case output shafts 4 are parallel to each other and are respectively rotatably connected in the rear axle housing 1; The double-speed idler 31 and the double-speed idler 32, the transfer case output shaft 4 is respectively movably connected with a non-double-speed driven gear 41 and a double-speed driven gear 42, and the transfer case driving gear 21 meshes with the non-double-speed idler 31, The non-double-speed idler 31 meshes with the non-double-speed driven gear 41, and the double-speed idler 32 meshes with the double-speed driven gear 42; the transfer case output shaft 4 is provided with a first clutch 5 and a second clutch 6, so The first clutch 5 is matched with the non-double-speed driven gear 4...

Embodiment 2

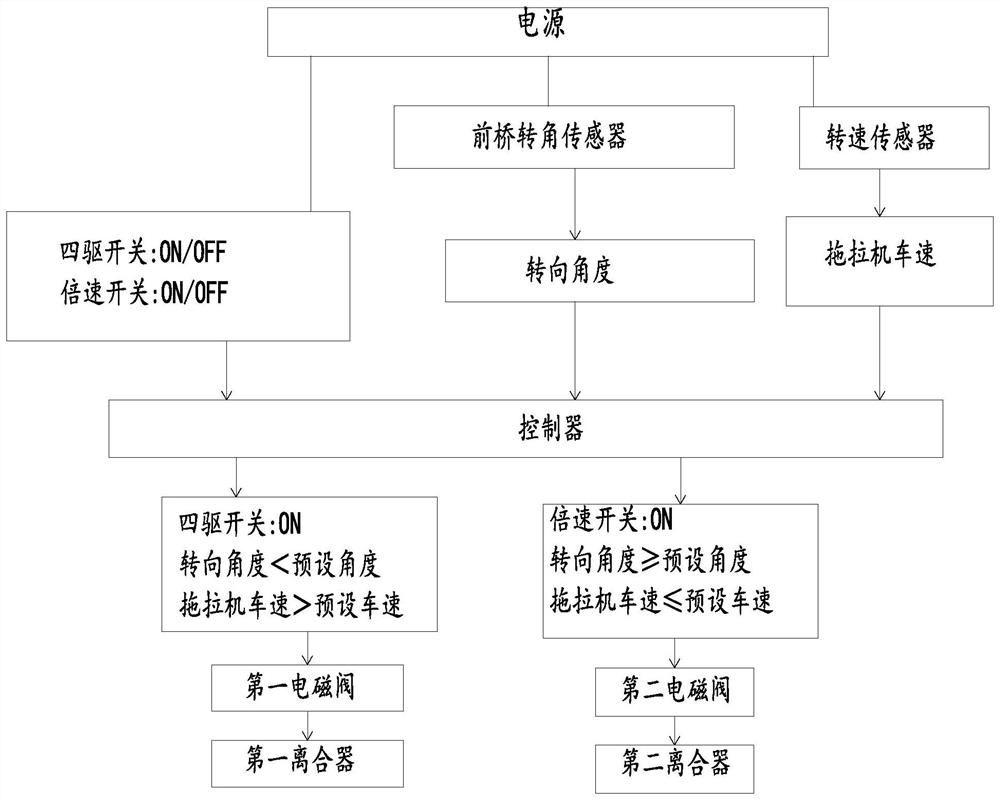

[0052] like figure 1 and figure 2 As shown, a tractor front wheel speed increasing steering system in this embodiment includes the tractor front wheel speed increasing steering device, and further includes: a front axle angle sensor, a rotational speed sensor and a controller, the front axle angle sensor is installed on the front axle and used to send the detected steering angle of the front axle to the controller, the speed sensor is mounted on the tractor chassis and used to send the detected speed of the tractor to the controller;

[0053] The controller is used for the steering angle of the front axle not less than the preset angle, and when the speed of the tractor is not greater than the preset speed, to control the second clutch to contact the double-speed driven gear, so that the transfer case output shaft 4 enters the double-speed mode;

[0054] The controller is used for the steering angle of the front axle not less than the preset angle, and when the speed of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com