Automatic pipeline butt joint device

A docking device and automatic technology, which is applied in the direction of workpiece clamping devices, hand-held tools, manufacturing tools, etc., can solve problems that affect the docking accuracy, damage to the suspension beam and collar, and offset, so as to improve accuracy and Work efficiency, smooth pulling process, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and embodiments.

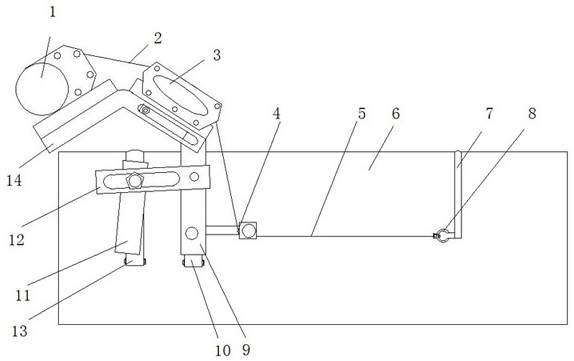

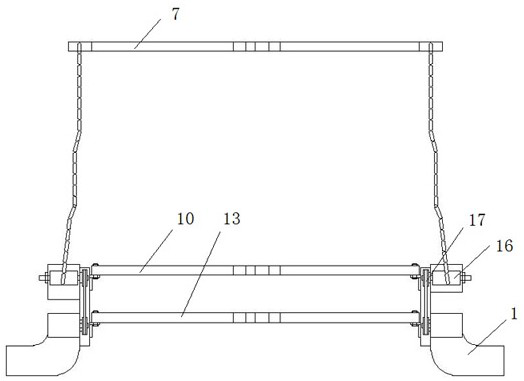

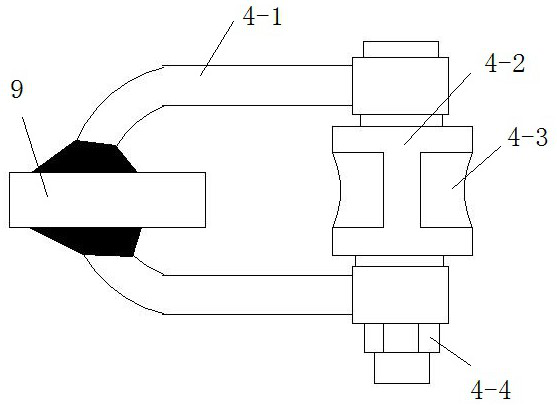

[0026] see attached Figure 1-4 , The automatic pipeline docking device disclosed in the present invention includes a snap ring and a stable frame which are sleeved on the pipeline, and the snap ring is connected with the driving mechanism through a pulling mechanism. The snap ring 7 is sleeved on a pipeline, the two stable frames are sleeved on the other pipeline in parallel, and the two groups of pulling mechanisms and driving mechanisms are respectively installed on the support frames on both sides of the pipeline to realize the pulling and docking of the pipeline. .

[0027] This automatic pipe docking device includes a stable frame set on the pipe and a snap ring 7, and the snap ring 7 is connected with a driving mechanism through a pulling mechanism.

[0028] The snap ring is a semi-circular ring structure, which is sleeved on the outer wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com