Method and filter device for filtering a liquid

A filter device and gas introduction device technology, applied in chemical instruments and methods, membranes, biological water/sewage treatment, etc., can solve the problems that the membrane has no flushing effect, does not include compensation inlet, and cannot flush the membrane, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

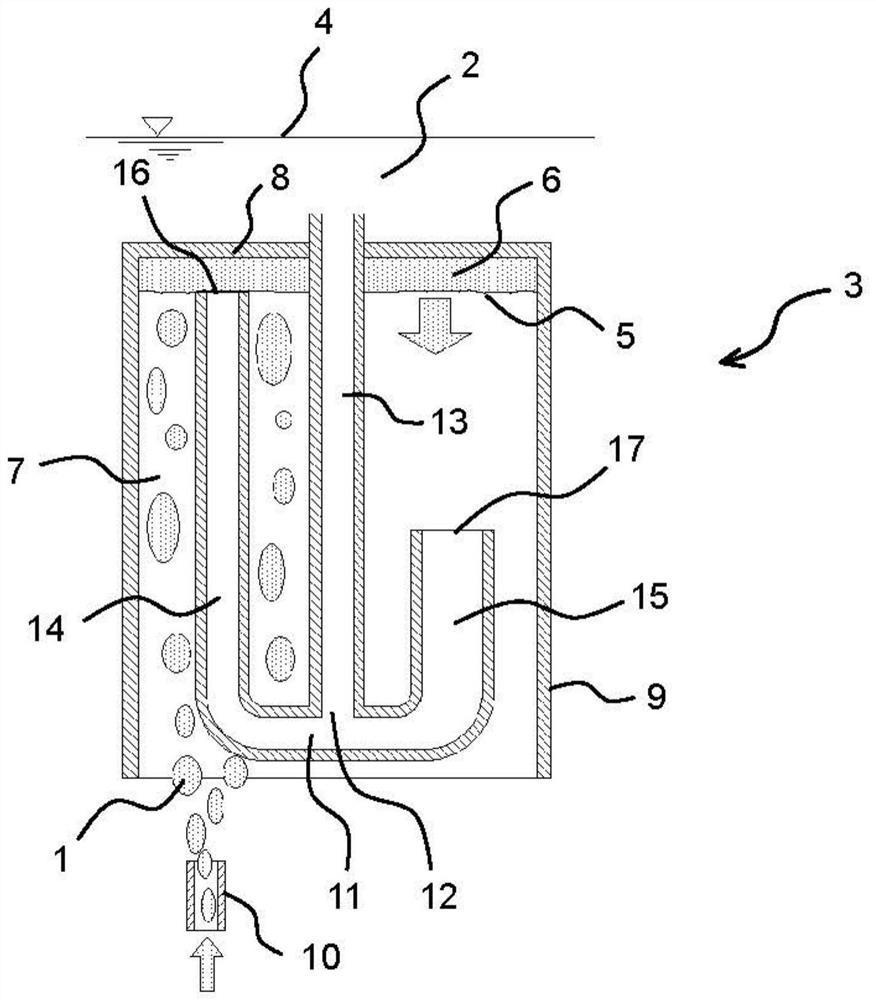

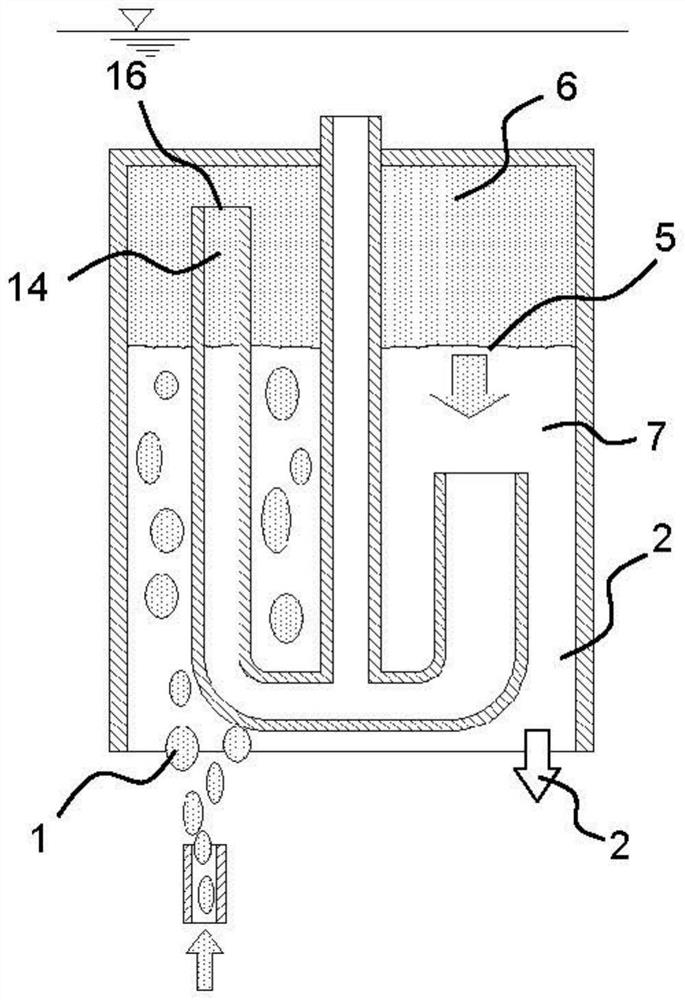

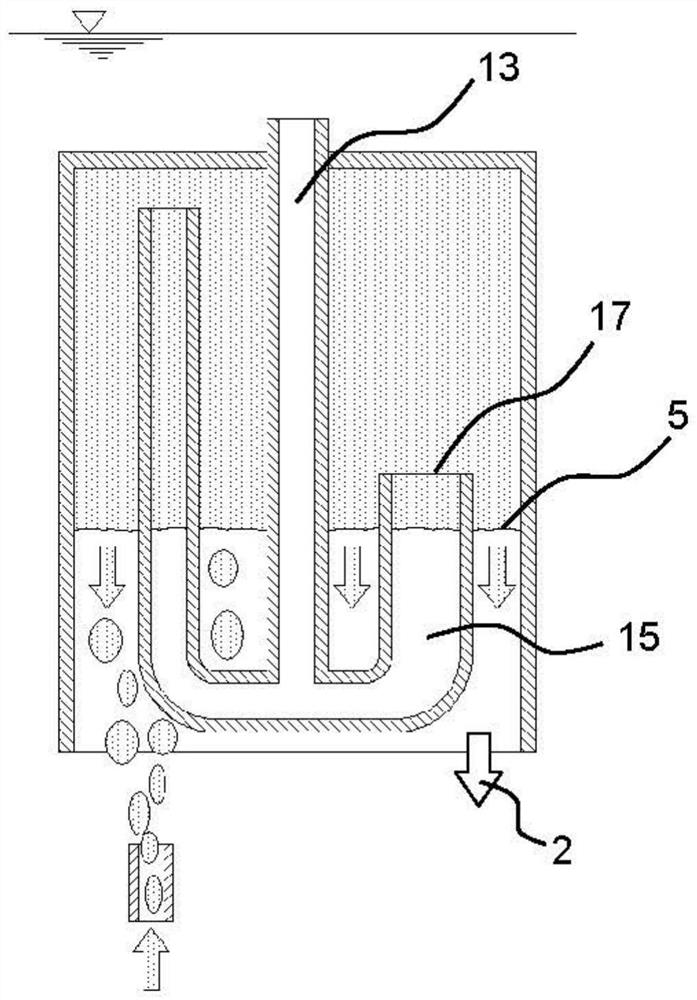

[0041] Figure 1a The process steps of the first method according to the invention are shown for introducing the gas 1 into the liquid 2 using the first gas introduction device 3 according to the invention shown in cross section.

[0042] The gas introduction device 3 comprises a gas volume 6 arranged below the surface 4 of the liquid 2 and defined by the liquid level 5 of the liquid 2 in a downward direction. The gas volume 6 is arranged in a gas collection chamber 7 defined by an upper wall 8 and side walls 9 . The gas 1 is introduced into the gas collection chamber 7 through a gas inlet 10 installed below and separated from the gas collection chamber 7 , filling the gas volume 6 and causing the liquid level 5 of the liquid 2 to drop. Therefore, the liquid 2 in the gas collection chamber 7 is displaced successively by the inflowing gas 1 in the downward direction at this point in time, and is replaced by the gas 1 .

[0043] The gas introduction device 3 according to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com