Pose measuring plate and method for automatically operating universal centrifugal machine through mechanical arm

A technology of pose measurement and measurement board, which is applied in the direction of centrifuges, measuring devices, optical devices, etc., can solve the problem of high cost, achieve cost saving, improve operation accuracy and efficiency, and facilitate application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

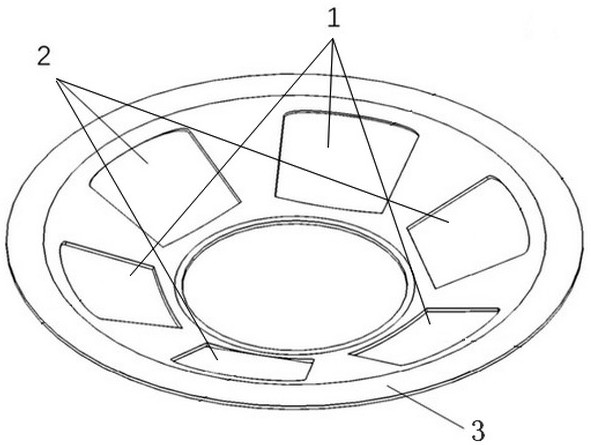

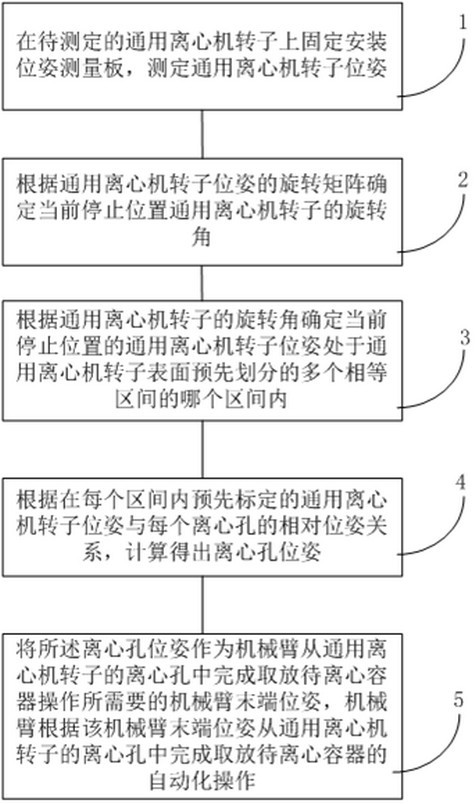

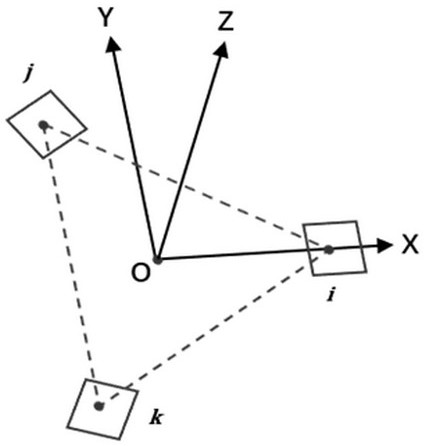

[0086] like figure 2 As shown in the figure, an embodiment of the present invention provides a method for automatically operating a universal centrifuge by a robotic arm. Before performing visual measurement and positioning on the centrifuge rotor, a pose measurement board is fixedly installed on the upper surface of the centrifuge rotor. The shape of the plate is the same as that of the upper surface of the centrifuge rotor, which can be tightly fitted on the upper surface of the centrifuge rotor. The rotor remains relatively static, that is, the two rotate synchronously; there are three through holes and three label installation grooves on the surface of the pose measurement board, and the through holes and the label installation grooves are spaced from each other and evenly distributed in a ring; the three label installation grooves Labels are placed in the slots, and each label has different predetermined graphic information;

[0087] In practical applications, the camera ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com