Airtightness detection device and detection method

A technology of airtight detection and detection block, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc., to achieve the effects of enhanced sealing, easy movement and positioning, and reduced damage

Inactive Publication Date: 2022-06-10

SHENZHEN TIANWEIDA ELECTRONICS

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] During the process of implementing this application, the inventors found that there are at least the following problems in this technology: the bottom of the product 6 and the workbench 11 are sealed by contacting the bottom of the product 6, which is prone to occur The problem of unreliable sealing, especially when the bottom of the product 6 is slightly uneven or the workbench 11 is worn, will affect the accuracy of the detection

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

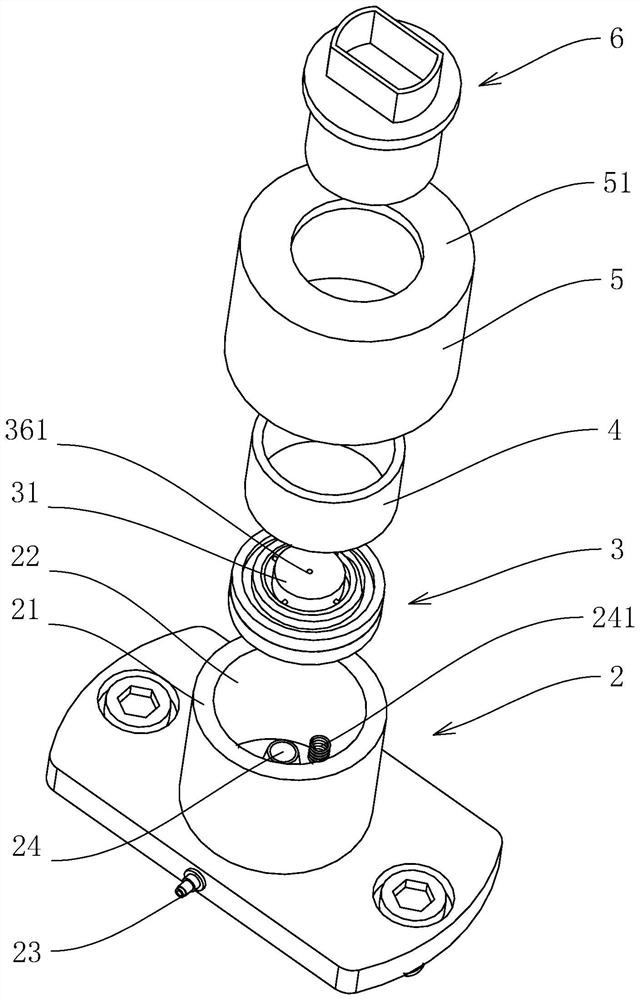

The invention discloses an airtightness detection device and a detection method, and relates to the technical field of detection equipment, the airtightness detection device comprises a machine table, the machine table comprises a workbench, an air cylinder and a pressing block are arranged on the machine table, an operation block is detachably connected to the workbench, a mounting cylinder is arranged on the surface of the operation block, the mounting cylinder comprises a containing cavity, and a detection block is vertically and slidably connected to the interior of the containing cavity; the operation block is provided with an air inlet end connected with an air pump, the middle of the surface of the detection block is provided with an air outlet hole which is communicated with the air inlet section and used for discharging air, the product covers the air outlet hole, the detection block is provided with a first elastic sealing ring and a second elastic sealing ring, and the first sealing ring and the second sealing ring are coaxially arranged. The bottom of the product is inserted between the first sealing ring and the second sealing ring, a first abutting piece is movably arranged in the mounting cylinder, a second abutting piece is movably arranged in the mounting cylinder, and the pressing block is pressed downwards to drive the first abutting piece and the second abutting piece to move. The air tightness detection device has the effect of detecting the air tightness of the product more accurately.

Description

technical field [0001] The present application relates to the technical field of testing equipment, in particular to an airtight testing device and a testing method. Background technique [0002] When some parts are produced, it is usually necessary to take samples to test the airtightness of the parts or to test the airtightness of the samples of the parts. At this time, airtightness testing equipment is usually used. [0003] refer to Figure 6 , is a kind of existing air-tightness testing equipment, is used for testing the product 6 that the bottom is cylindrical, and the top is the plastic jacket, and it comprises machine platform 1, and the press block 13 is arranged on the machine platform 1 by cylinder 12 lifting , the machine platform 1 includes a workbench 11, and an air outlet hole 361 connected to the air pump is opened on the workbench 11. By covering the air outlet hole 361 with the product 6, and after the briquetting block 13 is pressed against the top of the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M3/02

CPCG01M3/02

Inventor 周陵零熊道江杨光辉

Owner SHENZHEN TIANWEIDA ELECTRONICS

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com