Self-healing concrete crack repair inspection method

An inspection method and self-healing technology, applied in the direction of instruments, sustainable waste treatment, solid waste management, etc., can solve the problems of the test process, computational complexity, etc., and achieve the advantages of preliminary screening, easy-to-understand principles and simple molds Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

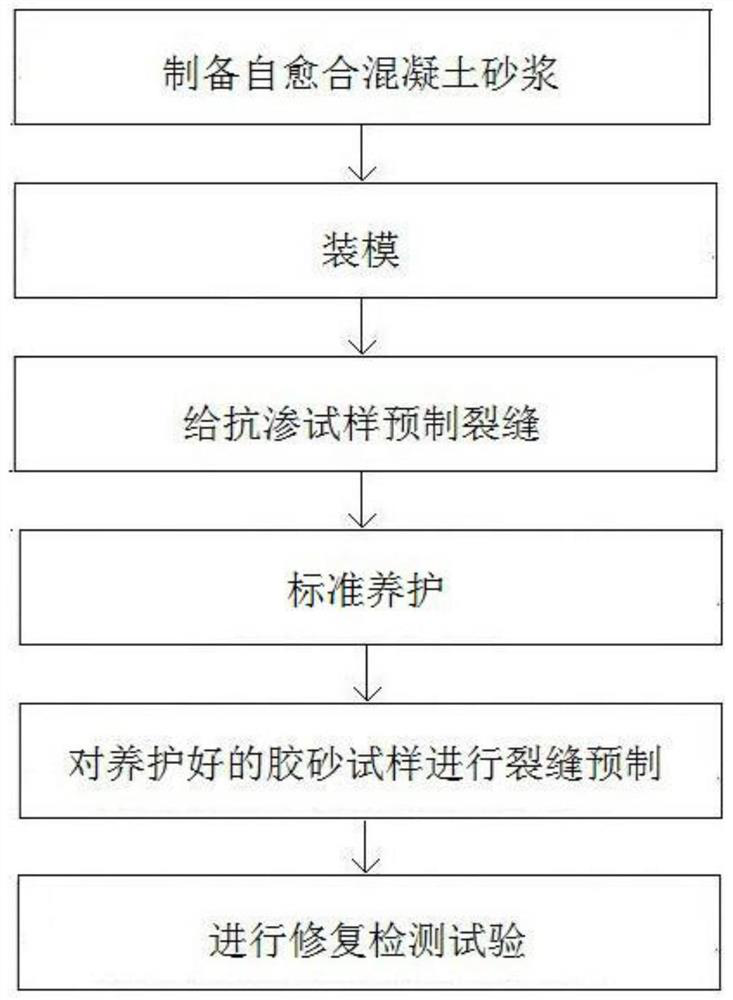

[0064] refer to Figure 1-Figure 3 A self-healing concrete crack repair inspection method shown, comprising the following steps:

[0065] Step 1: prepare self-healing concrete mortar;

[0066] Step 2: Molding

[0067] According to the preset crack repair test group and impermeability repair test group, put the self-healing mortar prepared in step 1 into different groups of test molds to prepare impermeability samples and mortar samples. Prepare at least three samples for each group;

[0068] Step 3: Prefabricate cracks for impermeable samples;

[0069] Step 4: Standard Care

[0070] For the mortar sample in step 2 and the impermeability sample with prefabricated cracks in step 3, the temperature is 20±2℃, and the humidity is not less than 95%.

[0071] Step 5: Prefabricate cracks on the cement sample cured in Step 4;

[0072] Step 6: Preset Mode Maintenance

[0073] The impermeable samples cured in step 4 and the mortar samples with prefabricated cracks in step 5 are re...

Embodiment 2

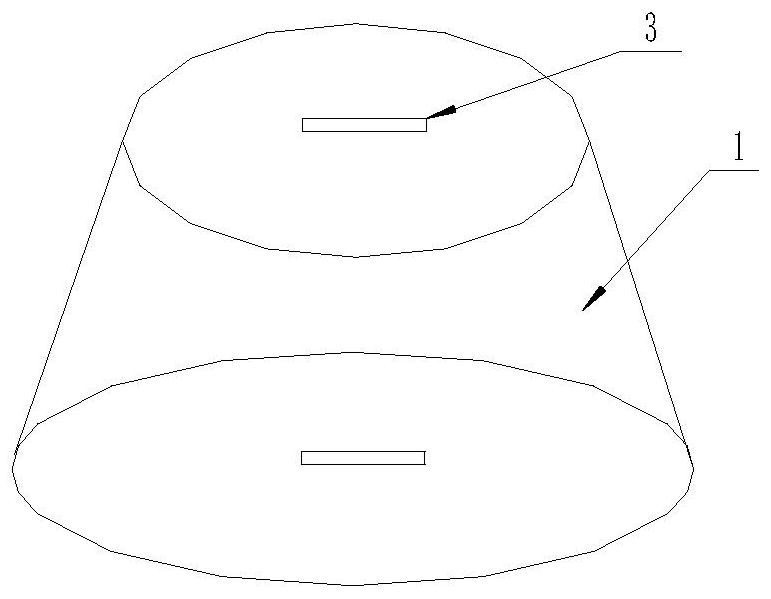

[0083] refer to figure 1 , figure 2 and image 3 A self-healing concrete crack repair inspection method is shown. On the basis of the first embodiment, the test mold in the second step includes a frustoconical metal test mold and a mortar test mold, and a frustoconical metal test mold. It is used to prepare impermeable samples, and the mortar mold is used to prepare mortar samples.

[0084] In the specific application, the frustoconical metal test mold and the mortar test mold used are the mortar impermeability test mold and crack observation stipulated in the construction industry standard of the People's Republic of China "Concrete Test Mode" (JG 237-2008). For the test mold, the test mold specified by the existing specification is adopted, and there is no need to customize the mold. The test method is universal and saves costs.

Embodiment 3

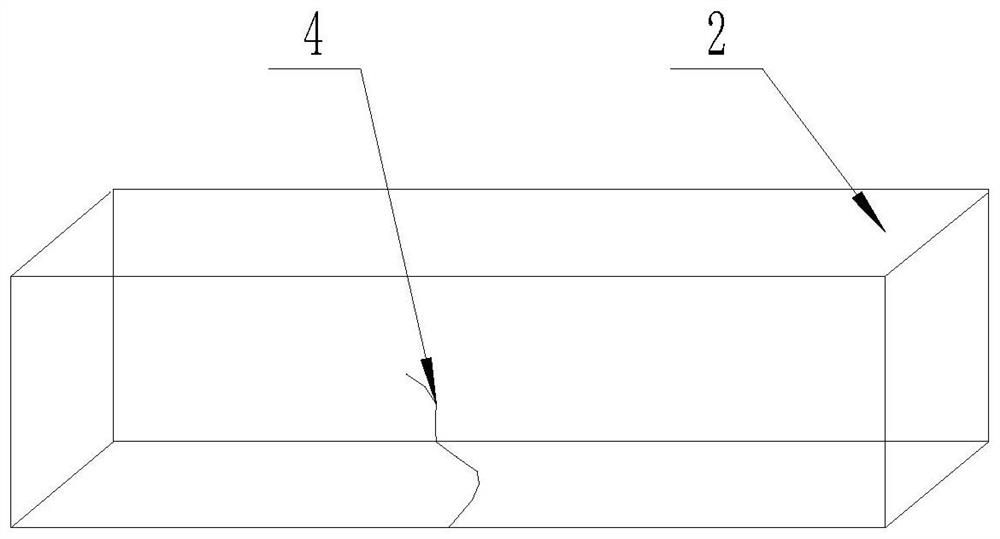

[0086] refer to figure 1 , figure 2 and image 3 A self-healing concrete crack repair inspection method is shown. On the basis of Embodiment 1, the specific method for prefabricating cracks in the impermeable sample in the third step is: preparing the impermeable sample test mold in the second step. Insert a blade with a width of 20mm and a thickness of 0.3-0.35mm wrapped with tape on the impermeable sample perpendicular to the surface of the sample, and the blade penetrates the upper and lower surfaces of the sample; shake the blade after 1.5-2.5 hours of mold installation to avoid sticking, and pull it out when it reaches initial setting A blade will do.

[0087] In this technical solution, the blade is shaken 1.5-2.5 hours after the mold is installed to avoid bonding. At this time, the mortar will harden to a certain extent, but the initial setting has not been reached. The shaking will not cause slight damage to the interior and surface of the mortar sample. Pre-cracks...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com