Driven disc assembly punching equipment for automobile clutch machining

A punching equipment and clutch technology, applied in metal processing equipment, drilling/drilling equipment, measuring/indicating equipment, etc., can solve the problems of inconvenient change of punching position, increase the scope of use, affect production efficiency, etc., to achieve Improve equipment adaptability, facilitate debugging, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

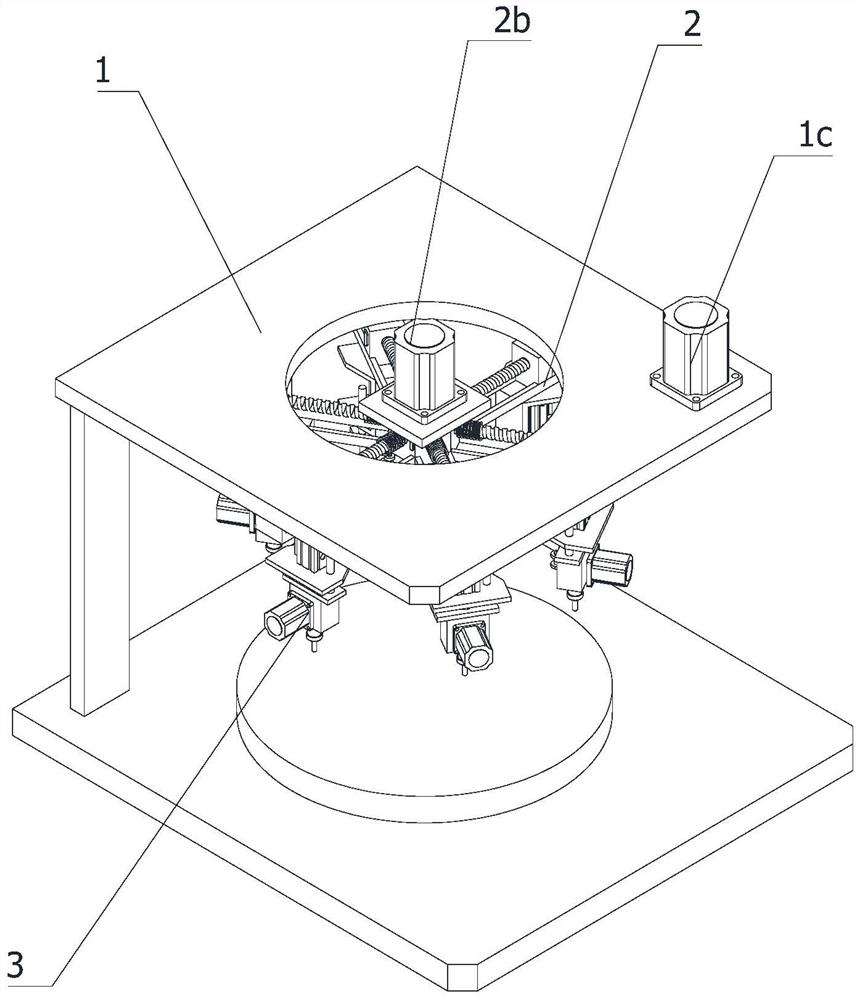

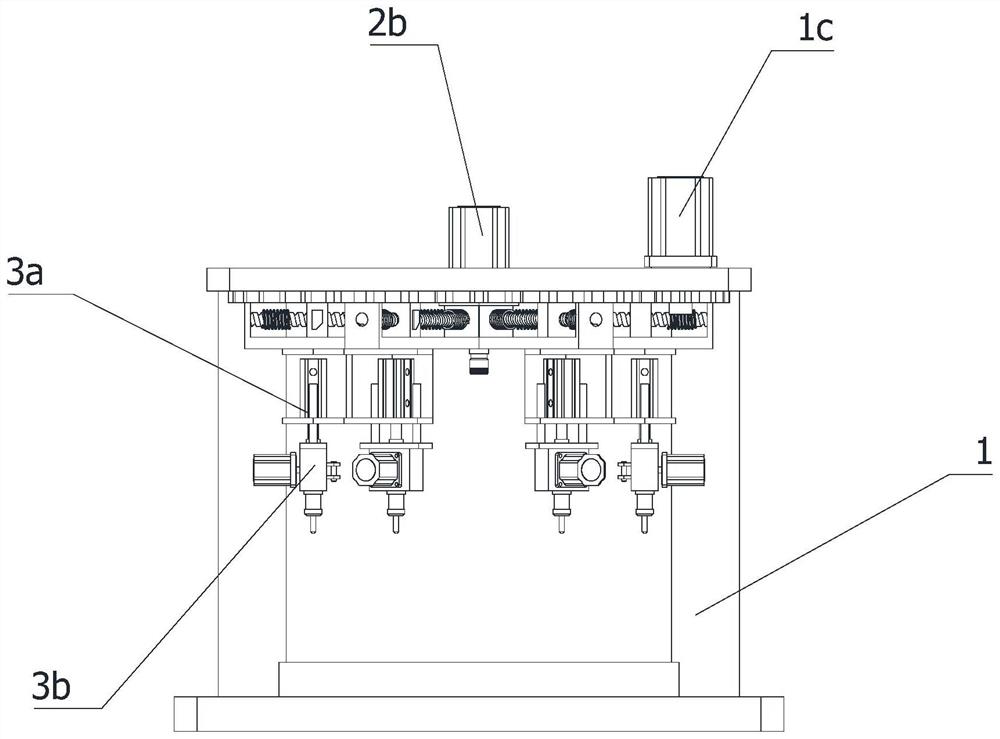

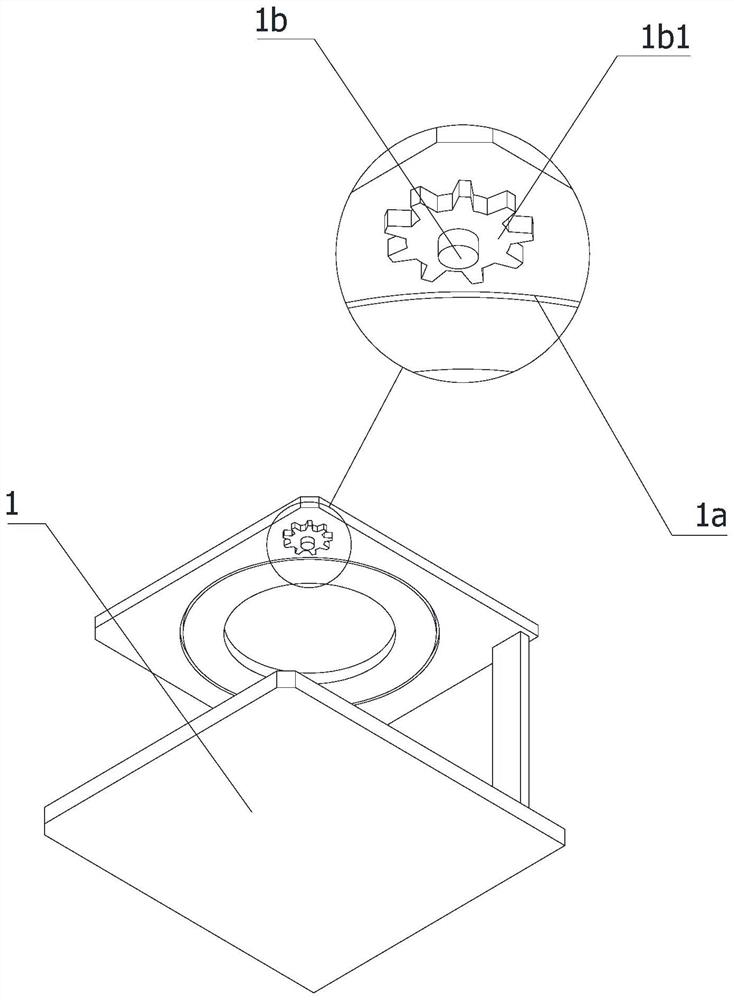

[0039] like Figure 1-10 As shown, this application provides:

[0040]A driven disc assembly punching device for automobile clutch processing, comprising a frame 1, on which a rotating frame 2, a rotating shaft 2a, a first rotating drive motor 2b and several drilling mechanisms 3 are arranged, The rotating frame 2 is a ring-shaped structure, the rotating frame 2 is rotatably located at the top of the frame 1, the rotating shaft 2a is vertically rotatable and is located in the center of the rotating frame 2, and the first rotating drive motor 2b is located on the rotating frame 2. And it is connected with the rotating shaft 2a by transmission. The circumference of the rotating shaft 2a is provided with the extension f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com