Hard functional candy liquid sandwich production device and method

A technology of functional candy and production equipment, which is applied in the fields of confectionary, confectionary industry, food science, etc., can solve the problems of affecting the taste of the sandwich, the outflow of explosive pulp, etc., and achieve the effect of improving the effect, effect and outstanding advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how to apply technical means to solve technical problems and achieve technical effects in the present application.

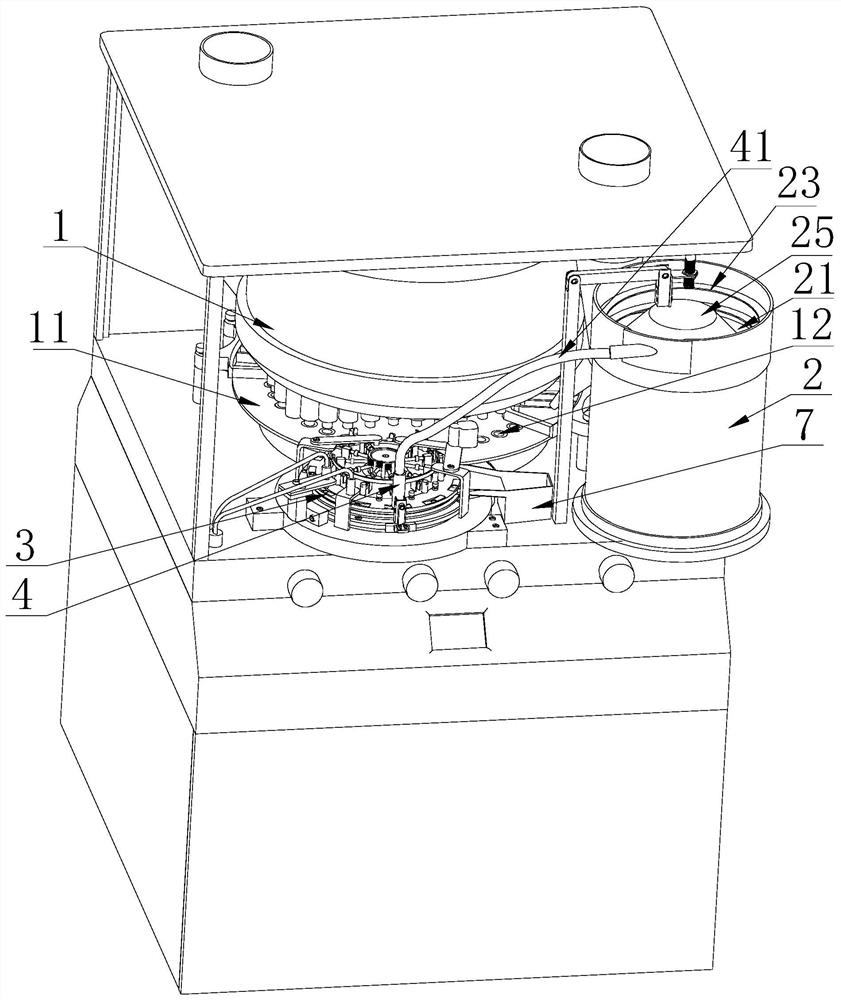

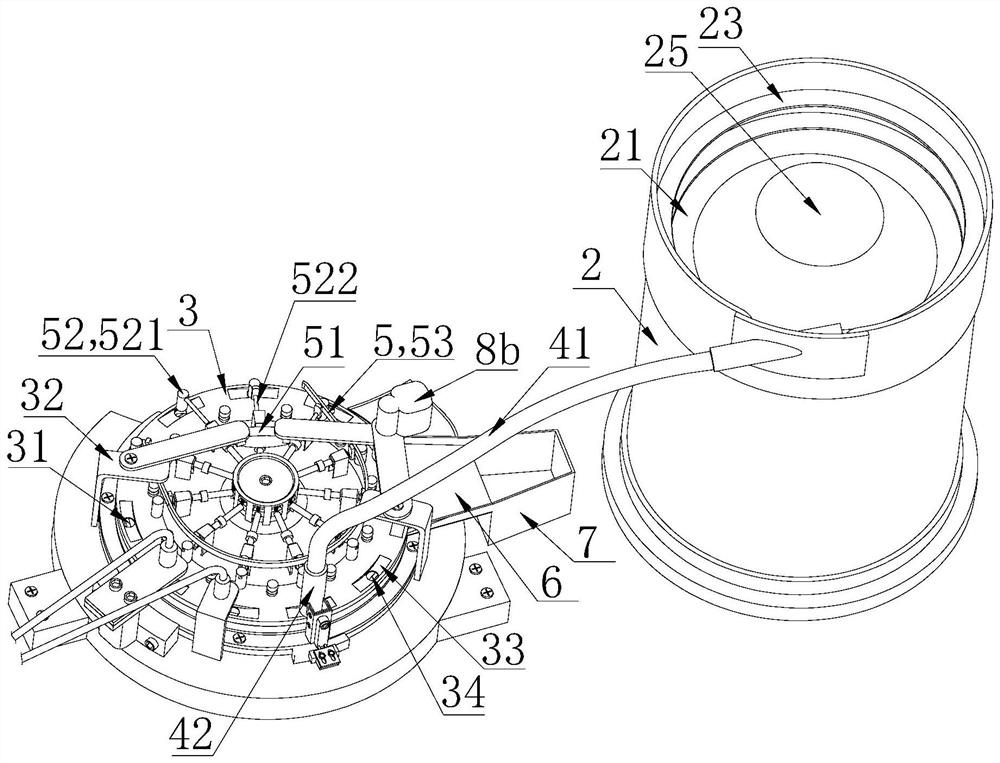

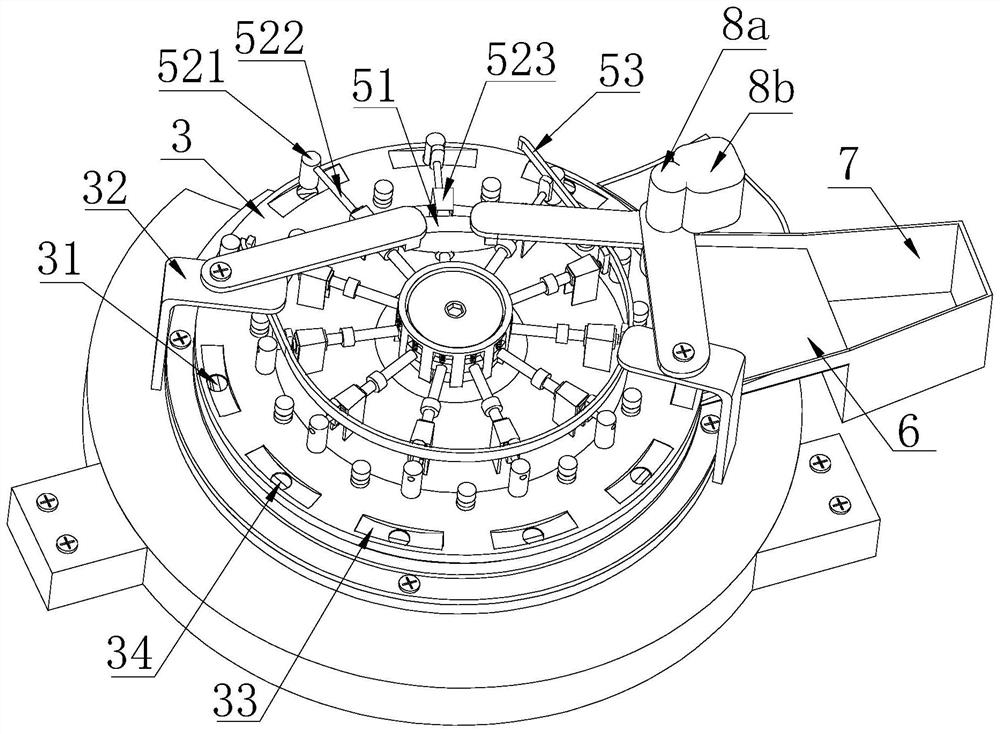

[0040] Please refer to Figure 1 to Figure 8 As shown, the present invention provides a hard functional candy liquid center sandwich production device, including a rotary tablet press 1, an automatic sugar unwinding machine 2, a discharging component 4 and a core filling disc 3, wherein the core filling disc 3 and A transmission component can be arranged between the rotary tablet presses 1 to make the two rotate in opposite directions. The middle die turntable 12 of the rotary air compressor is provided with a middle die, and the inner cavity of the middle die is a punching hole 12 for tablet pressing, which is fully automatic. In the candy production pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com