Single-transverse-rail anti-unbalance-loading monorail hoisting system and using method thereof

A monorail crane and monorail technology, applied in the direction of the rail system, load suspension components, load pulleys, etc., can solve the problems of reduced work efficiency, rail deformation, safety hazards, etc., and achieves simple structure, automatic force balance, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

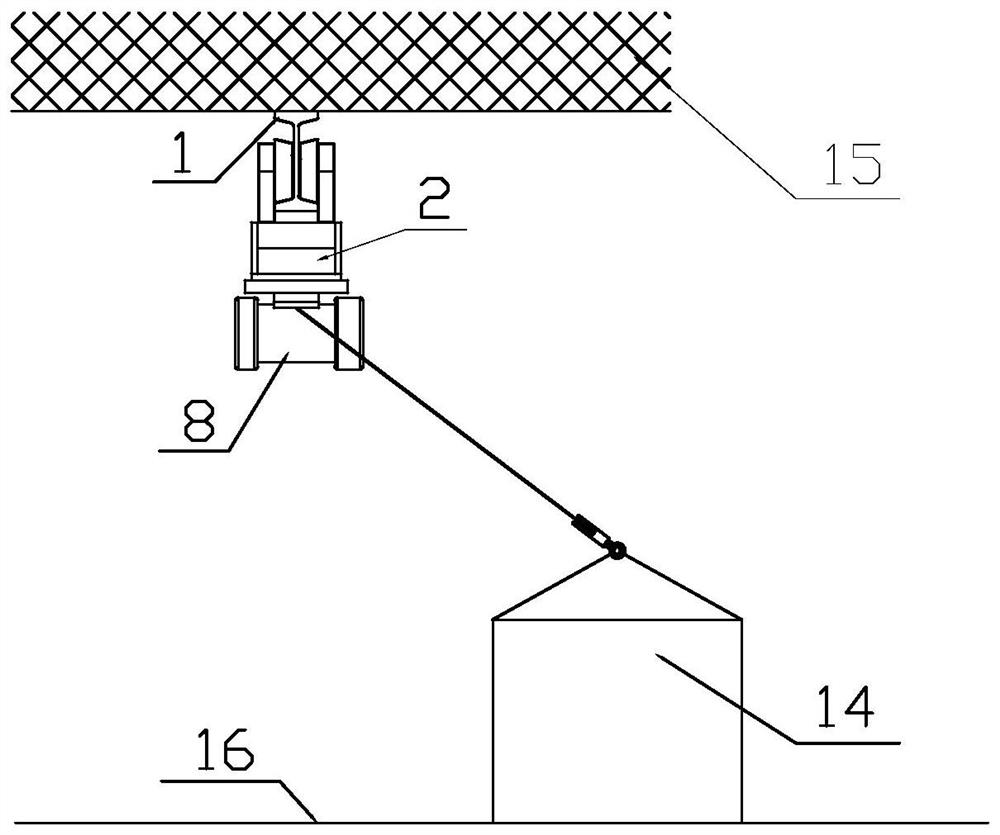

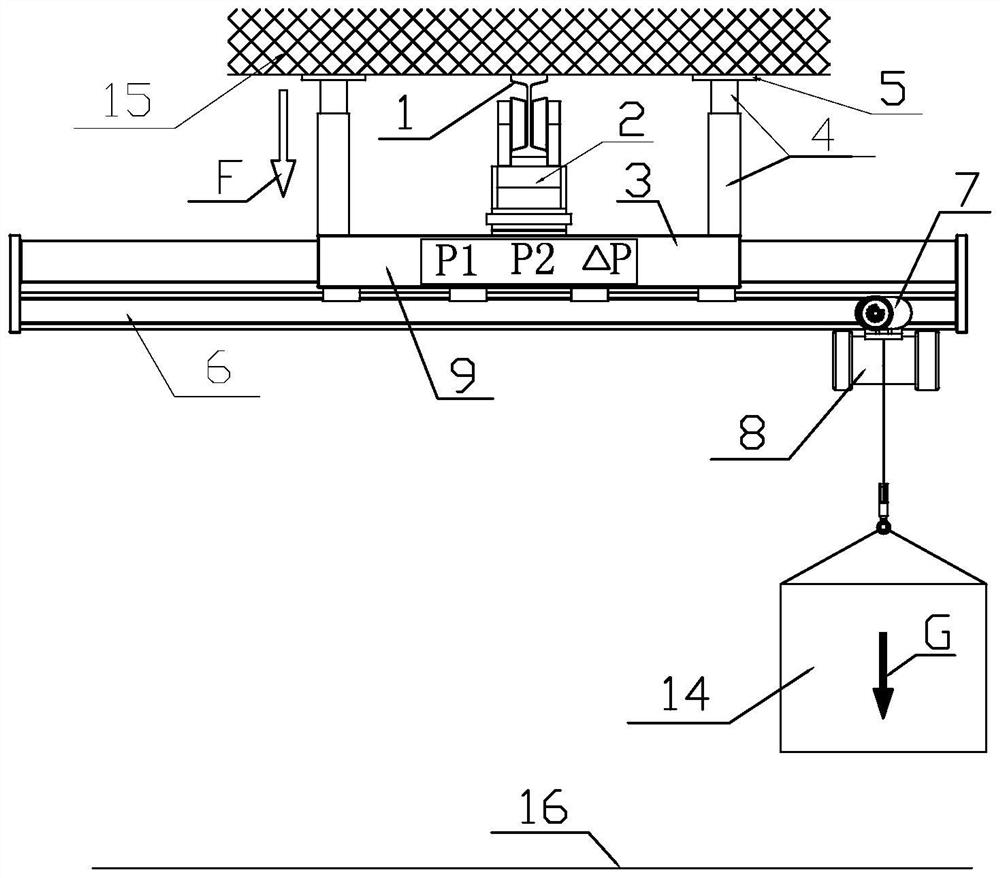

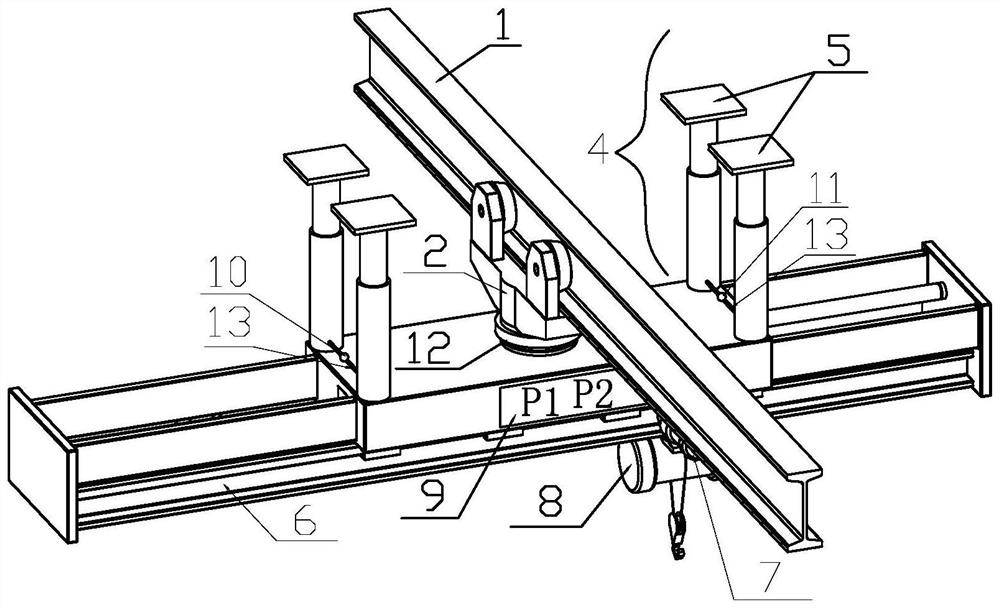

[0027] Implementation mode one: if Figure 2-4 As shown, the monorail anti-eccentric load monorail hoisting system of the present invention includes a monorail traveling mechanism 2 and a lifting box 3, and the lifting box 3 is fixed below the monorail traveling mechanism 2, and is characterized in that the four corners of the lifting box 3 A hydraulic support leg 4 is vertically fixed on the top, and the top of each hydraulic support leg 4 is respectively provided with a supporting plate 5, and is equipped with a hydraulic control valve group (not shown in the figure), and the four hydraulic support legs 4 are plunger Oil cylinder, including cylinder barrel, plunger, guide sleeve, sealing ring and gland respectively, is equipped with monorail 1. The inner cavity at the root of the cylinder barrel of the two hydraulic support legs on the left side communicates through high-pressure pipe 13, and the two hydraulic support legs on the right side communicate with each other through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com