Preparation device and preparation method for instant rice

A technology for preparing a device and instant rice, which is applied in the directions of cleaning methods, chemical instruments and methods, cleaning methods and utensils using liquids, etc., can solve the problems of high production cost and low work efficiency, and can improve the storage period and taste. , the effect of increasing the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

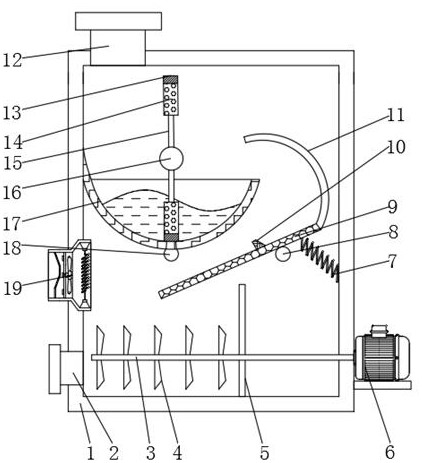

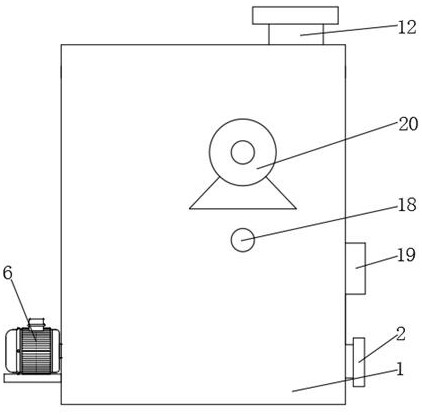

[0038] refer to Figure 1-5 , a preparation device for instant rice, comprising a box body 1, the top of the box body 1 is welded with a feeding pipe 12, one side of the box body 1 is welded with a discharge pipe 2, and the outer wall of one side of the box body 1 passes through The first motor 20 is fixed with bolts, and one end of the output shaft of the first motor 20 is fixed with a first transmission rod 16 through bolts, the first transmission rod 16 is located inside the box 1, and one side of the first transmission rod 16 is bolted A connecting rod 15 is fixed, and one end of the connecting rod 15 is fixed with a filter plate 14 by bolts, and a cleaning cylinder 17 is fixed on one side of the inner wall of the box body 1 by bolts, and is rotated by the first transmission rod 16 under the driving of the first motor 20 , under the cooperation of the connecting rod 15, the filter plate 14 is driven to rotate, and when rotating clockwise, the rice in the cleaning cylinder ...

Embodiment 2

[0051] refer to Figure 1-5 , a preparation device for instant rice, comprising a box body 1, the top of the box body 1 is welded with a feeding pipe 12, one side of the box body 1 is welded with a discharge pipe 2, and the outer wall of one side of the box body 1 passes through The first motor 20 is fixed with bolts, and one end of the output shaft of the first motor 20 is fixed with a first transmission rod 16 through bolts, the first transmission rod 16 is located inside the box 1, and one side of the first transmission rod 16 is bolted A connecting rod 15 is fixed, and one end of the connecting rod 15 is fixed with a filter plate 14 by bolts, and a cleaning cylinder 17 is fixed on one side of the inner wall of the box body 1 by bolts, and is rotated by the first transmission rod 16 under the driving of the first motor 20 , under the cooperation of the connecting rod 15, the filter plate 14 is driven to rotate, and when rotating clockwise, the rice in the cleaning cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com