A liquid adding device and liquid adding method

An equipment and liquid tank technology, which is applied in the field of liquid addition equipment and liquid addition, can solve the problems of lack of liquid addition equipment and uniform liquid addition equipment, and achieve the effects of improving convenience, precise liquid addition, and strong usability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

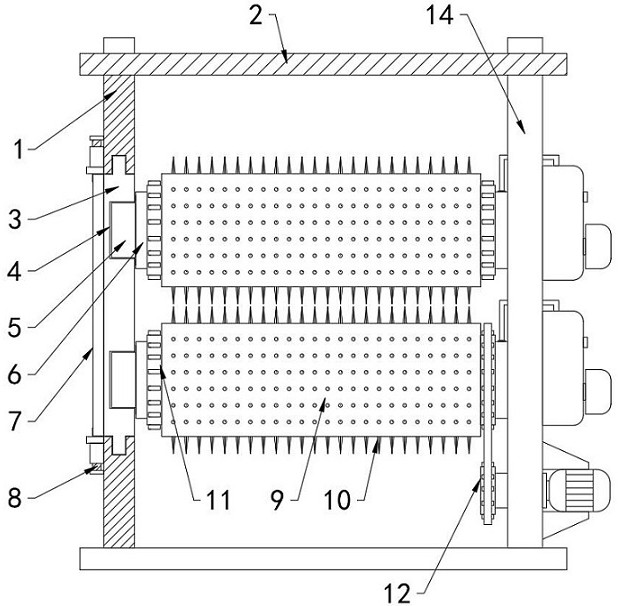

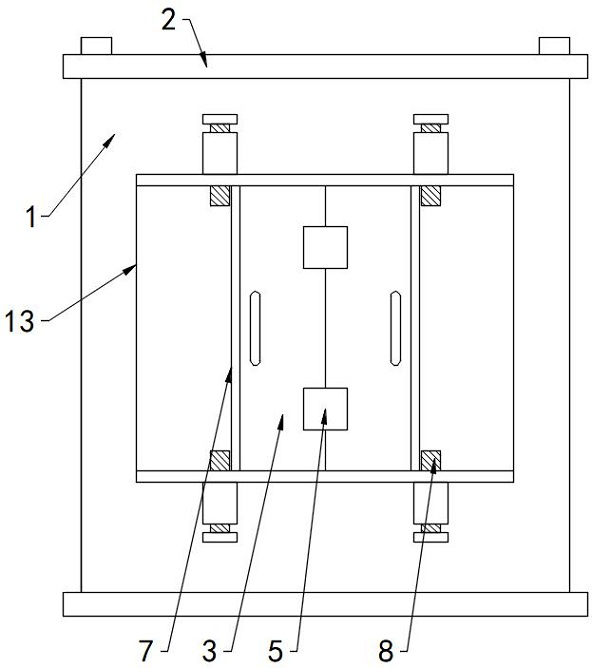

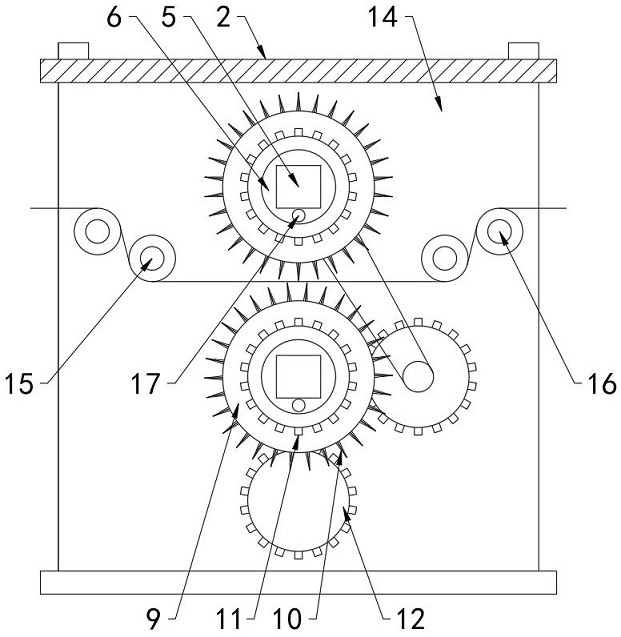

[0036] refer to Figure 1-5 , a liquid dosing device, including:

[0037] The top plate 2, the left side plate 1 and the right side plate 14 are respectively installed on both sides of the bottom of the top plate 2, the bottom of the left side plate 1 and the right side plate 14 is installed with a base, and the left side plate 1 and the right side plate 14 are respectively installed with Lead-in roller 15 and lead-out roller 16;

[0038] The fixed shaft 6 is provided with at least one group, and each group is provided with two. One end of the two fixed shafts 6 is fixedly connected to the right side plate 14, and the other end is detachably installed with the left side plate 1. The fixed shaft 6 A liquid storage cavity is arranged inside, and a positioning box 21 is movably arranged on the outer wall of the liquid storage cavity. The upper end surface of the positioning box 21 is an open end, and the lower end surface of the positioning box 21 is provided with a plurality of...

Embodiment 2

[0044] refer to Figure 1-5 , a liquid dosing device, including:

[0045] The top plate 2, the left side plate 1 and the right side plate 14 are respectively installed on both sides of the bottom of the top plate 2, the bottom of the left side plate 1 and the right side plate 14 is installed with a base, and the left side plate 1 and the right side plate 14 are respectively installed with Lead-in roller 15 and lead-out roller 16;

[0046] The fixed shaft 6 is provided with at least one group, and each group is provided with two. One end of the two fixed shafts 6 is fixedly connected to the right side plate 14, and the other end is detachably installed with the left side plate 1. The fixed shaft 6 A liquid storage cavity is arranged inside, and a positioning box 21 is movably arranged on the outer wall of the liquid storage cavity. The upper end surface of the positioning box 21 is an open end, and the lower end surface of the positioning box 21 is provided with a plurality of...

Embodiment 3

[0053] refer to Figure 1-5 , a liquid dosing device, including:

[0054] The top plate 2, the left side plate 1 and the right side plate 14 are respectively installed on both sides of the bottom of the top plate 2, the bottom of the left side plate 1 and the right side plate 14 is installed with a base, and the left side plate 1 and the right side plate 14 are respectively installed with Lead-in roller 15 and lead-out roller 16;

[0055] The fixed shaft 6 is provided with at least one group, and each group is provided with two. One end of the two fixed shafts 6 is fixedly connected to the right side plate 14, and the other end is detachably installed with the left side plate 1. The fixed shaft 6 A liquid storage cavity is arranged inside, and a positioning box 21 is movably arranged on the outer wall of the liquid storage cavity. The upper end surface of the positioning box 21 is an open end, and the lower end surface of the positioning box 21 is provided with a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com