Rotational flow vertical shaft flood discharge tunnel with staggered platform type volute chamber small flip bucket

A technology of flood discharge tunnel and vortex chamber, which is applied in marine engineering, construction, barrage/weir, etc., can solve the problems of increased risk of cavitation and cavitation on the shaft wall, increased engineering construction difficulty, complicated structure of aeration facilities, etc. The ability to resist cavitation and cavitation, reduce the difficulty of construction, and the effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

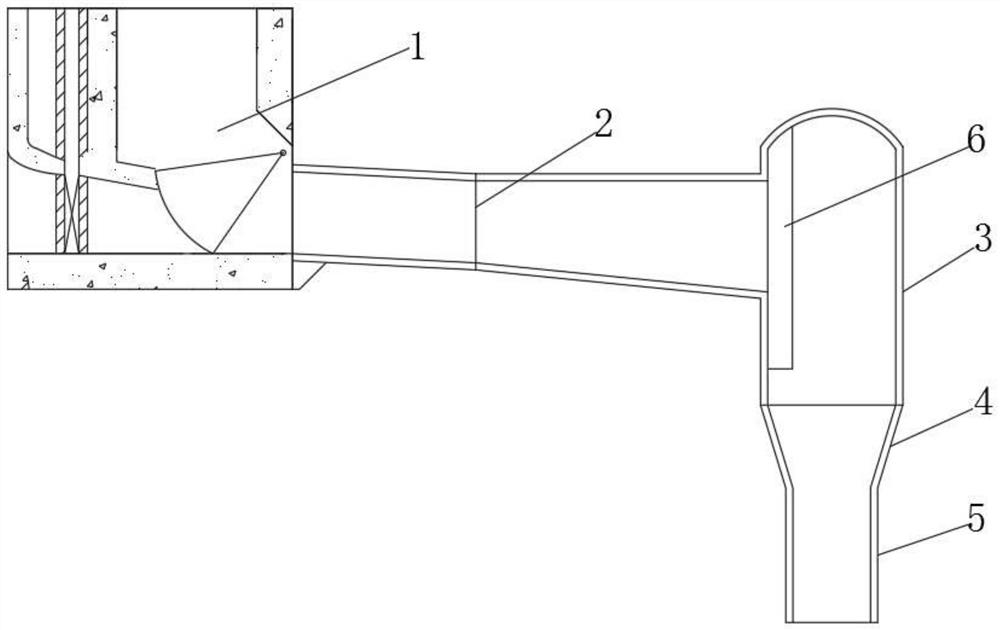

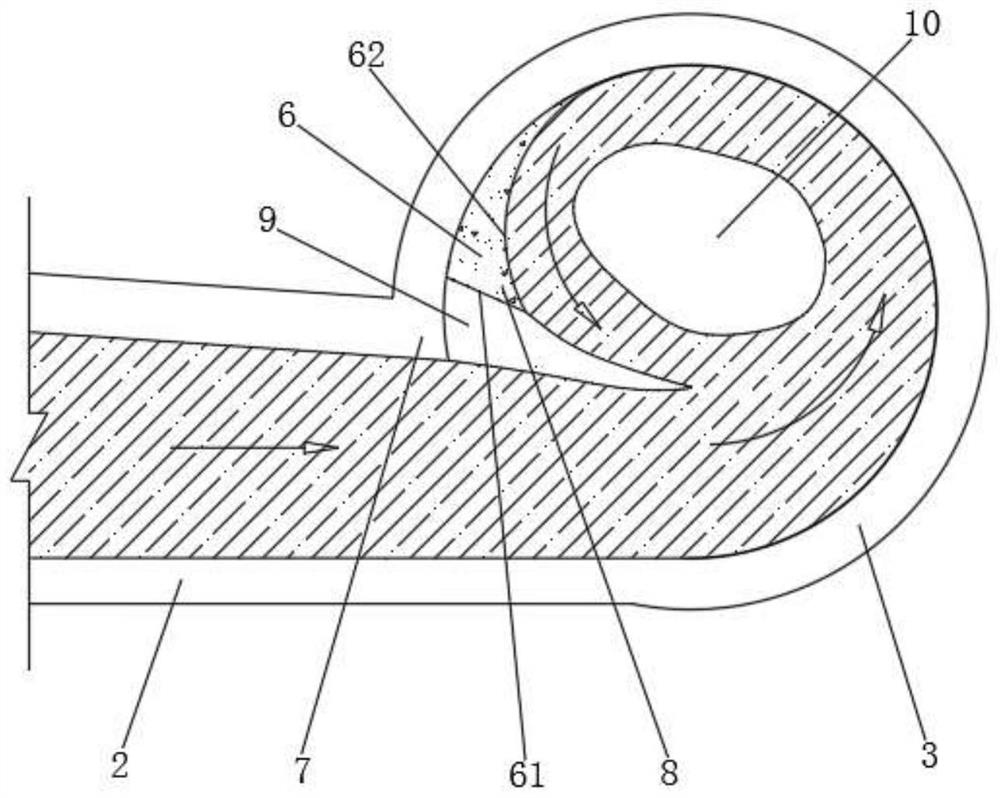

[0023] A swirl shaft flood discharge tunnel with staggered vortex chambers and small ridges, refer to figure 1 , figure 2 , including the sluice chamber inlet 1, the upper flat section 2, the vortex chamber 3, the constriction section 4 and the vertical shaft straight section 5 connected in sequence, and the inner wall of the vortex chamber 3 close to the upper flat section 2 is provided with a diversion ridge 6 , the diversion riser 6 includes a vertical surface 61 and a diversion arc surface 62 intersecting the vertical surface 61, combined with image 3 , the swirl shaft flood discharge tunnel also includes the incoming flow aeration sill 7 and the swirl aeration sill 8; the incoming flow aeration sill 7 flows along the incoming water body from the vertical wall of the upper flat section 2 close to the diversion sill 6 The end of the direction to the vertical surface 61 of the diversion riser 6 suddenly expands to form, and the swirl aeration riser 8 is formed by the div...

Embodiment 2

[0028]The difference between this embodiment and Embodiment 1 is that in this embodiment, when building the diversion riser 6, the overall position of the diversion riser 6 is kept unchanged, and the diversion riser in Embodiment 1 is reduced. 6, the specific implementation method is: the vertical surface 61 of the diversion riser 6 is translated in a direction away from the upper flat section 2, the position of the diversion arc surface 62 of the diversion riser 6 remains unchanged, and the diversion The translation direction of the vertical surface 61 of the raised ridge 6 is perpendicular to the flow direction of the incoming water body in the upper flat section 2, and the vertical surface 61 of the diversion raised ridge 6 is parallel to the vertical wall surface of the upper flat section 2, and at this time the vertical The arc length of the side wall of the vortex chamber 3 between the intersection line of the straight face 61 and the inner wall of the vortex chamber 3 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com