Seed cultivating and screening equipment for rising and falling type water pumping and soaking farm

A screening equipment and lift-type technology, applied in solid separation, chemical instruments and methods, wet separation, etc., can solve problems such as incomplete germination, inability to cultivate, and reduced water immersion rate of seeds, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

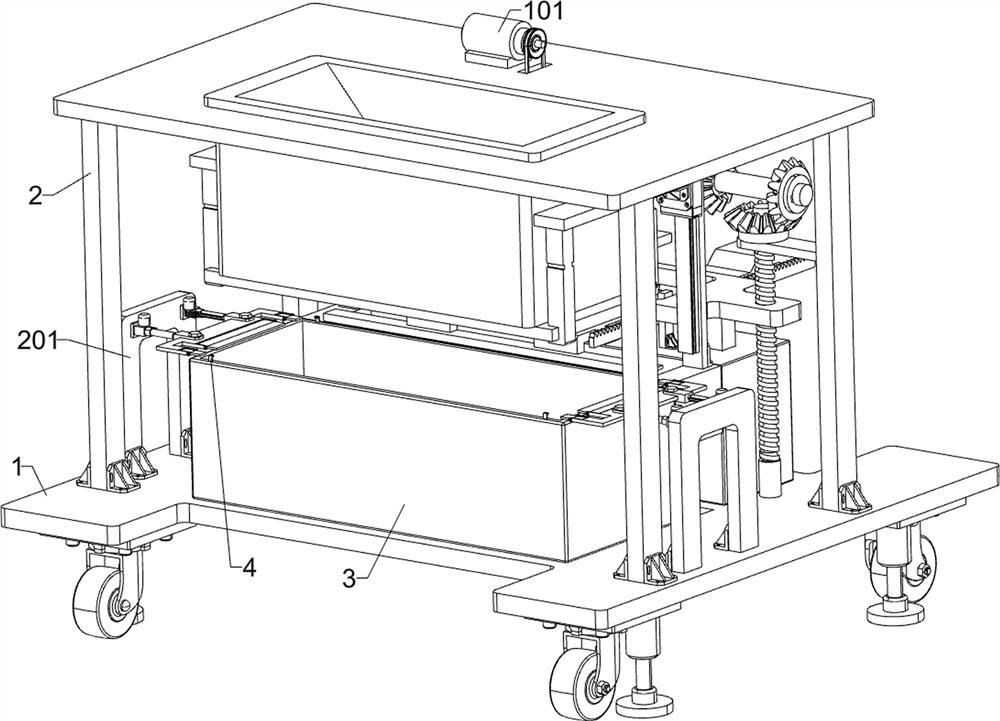

[0039] A lifting type pumping soaking farm seed cultivation and screening equipment, according to Figure 1-14 As shown, it includes a bottom plate 1, a support frame 2, a immersion pool 3, a first rack 4, a scraping mechanism, a blocking mechanism, a transmission mechanism and a soaking mechanism; the bottom plate 1 is connected with a support frame 2 by bolts; The upper part of the immersion pool 3 is placed with a immersion pool 3; the upper surface of the immersion pool 3 has four first racks 4 in a rectangular array; the support frame 2 is connected with a scraping mechanism; the bottom plate 1 is connected with a blocking mechanism; the support frame 2 is equipped with a transmission mechanism. The mechanism is connected with the scraping mechanism; the lower surface of the support frame 2 is connected with a soaking mechanism, and the soaking mechanism is connected with the transmission mechanism.

[0040] Working process: first place the bottom plate 1 and the support ...

Embodiment 2

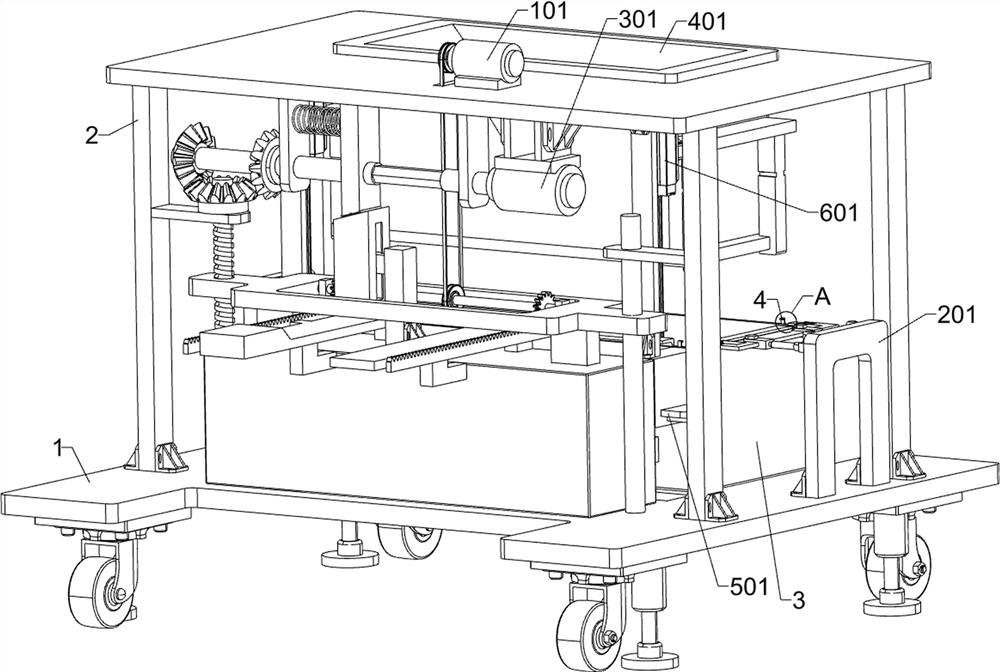

[0042] On the basis of Example 1, according to figure 1 with Figure 4-14 As shown, the transmission mechanism includes a mounting bracket 301, a second motor 302, a first bracket 303, a moving bracket 304, a spring 305, a second bracket 306, a second transmission shaft 307, a hexagonal slide bar 308, a third transmission shaft 309, The first bevel gear 3010, the second bevel gear 3011, the third bevel gear 3012, the screw mandrel 3013, the moving platen 3014, the polished rod 3015 and the water tank 3016; The surface bolt is connected with the second motor 302; the output shaft of the second motor 302 is fixedly connected with the second transmission shaft 307; the outer surface of the second transmission shaft 307 is connected with the first support 303; Fixed connection; the lower surface of the left part of the support frame 2 is fixedly connected with the second bracket 306; the bottom of the second bracket 306 is rotatably connected with the third transmission shaft 309...

Embodiment 3

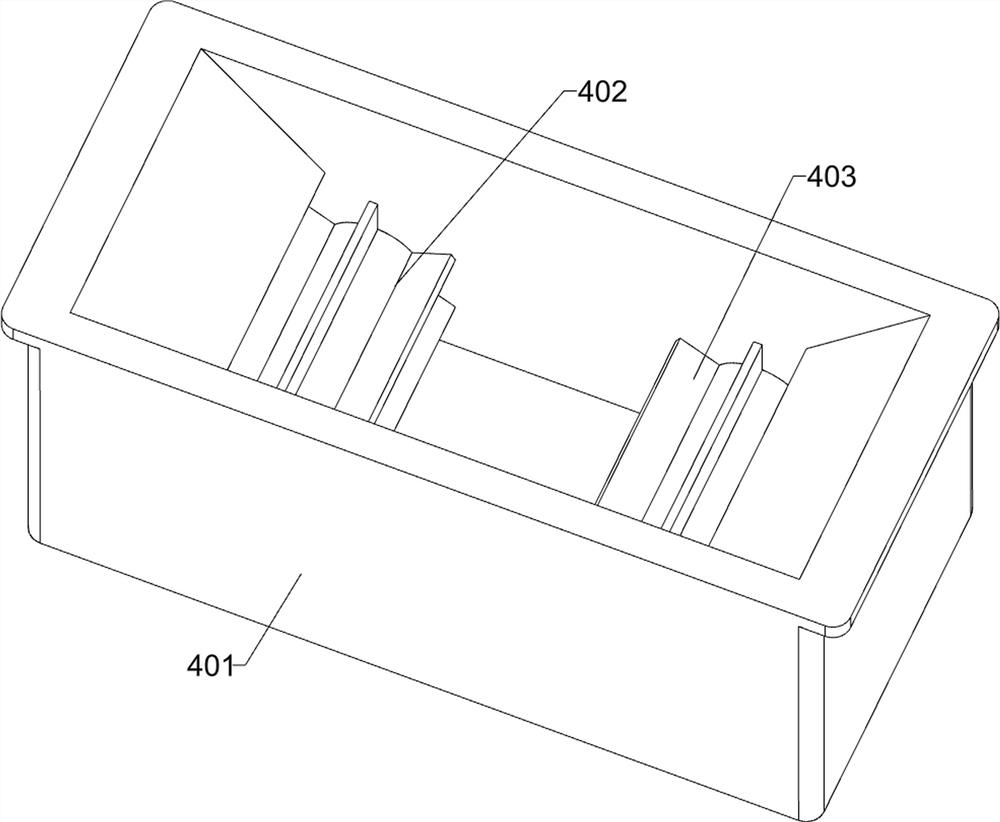

[0050] On the basis of Example 2, according to figure 1 with Figure 15-16 As shown, a feeding mechanism is also included, and the support frame 2 is connected with a feeding mechanism. The feeding mechanism includes a fixed frame 401, a first electric rotating plate 402 and a second electric rotating plate 403; the top of the supporting frame 2 is fixedly connected with a fixed frame 401 ; the left part of the fixed frame 401 is rotatably connected with a first electric rotating plate 402 ; the right part of the fixed frame 401 is rotatably connected with a second electric rotating plate 403 .

[0051] The steering of the first electric rotating plate 402 and the second electric rotating plate 403 are opposite, and are used for evenly distributing the poured seeds.

[0052] First turn on the first electric turntable 402 and the second electric turntable 403, the operator pours the seeds to be screened by the farm from the fixed frame 401, and the poured seeds pass through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com