Tree planting robot

A technology for robots and saplings, applied in planting methods, manipulators, excavation/covering trenches, etc., can solve the problems of cumbersome and complex mechanical structure, inflexible movement control, complex control algorithm, etc., and achieve simple device structure and reduce motion design. requirements, the effect of improving work accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

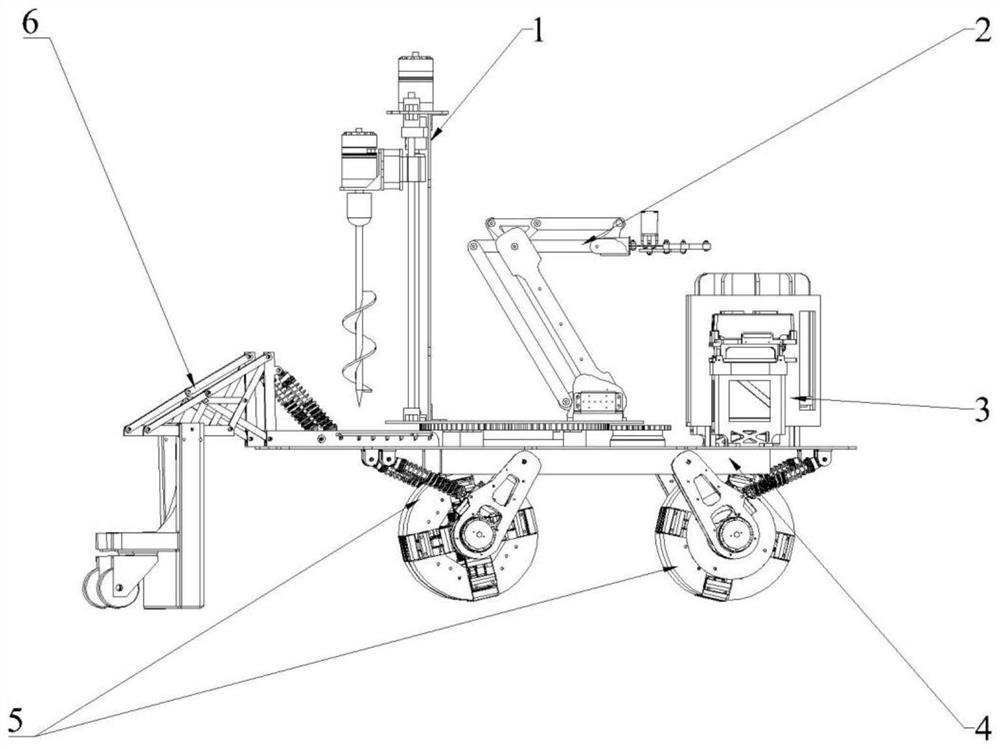

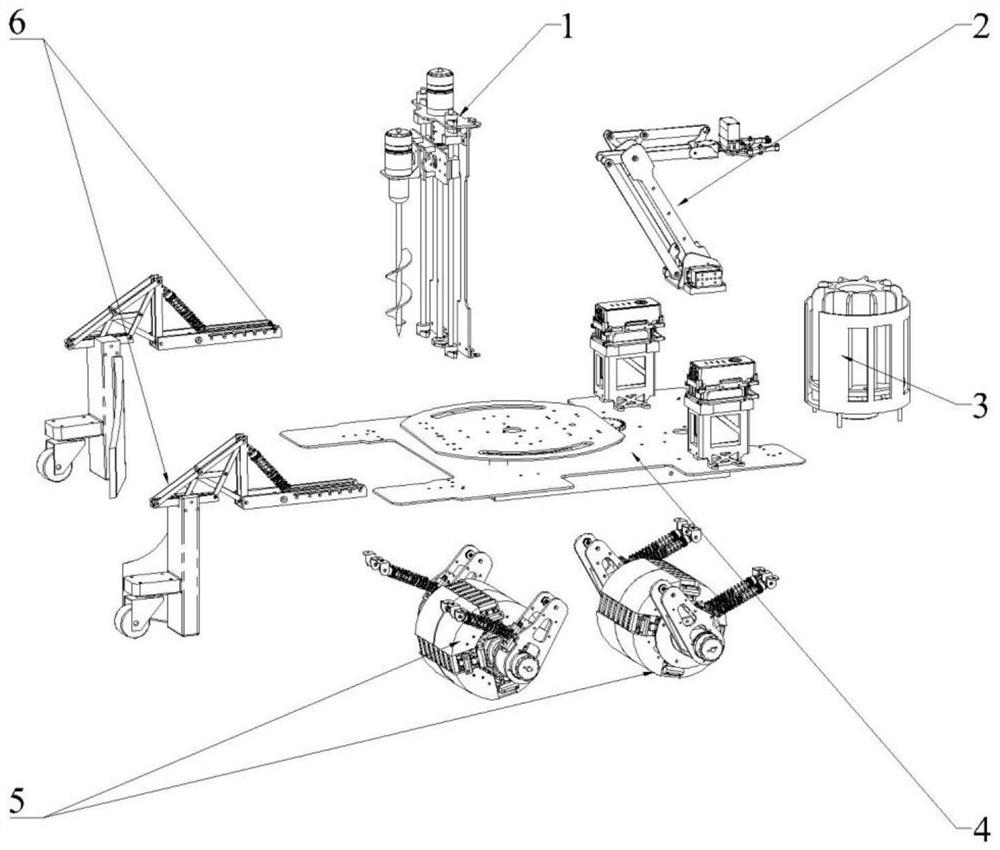

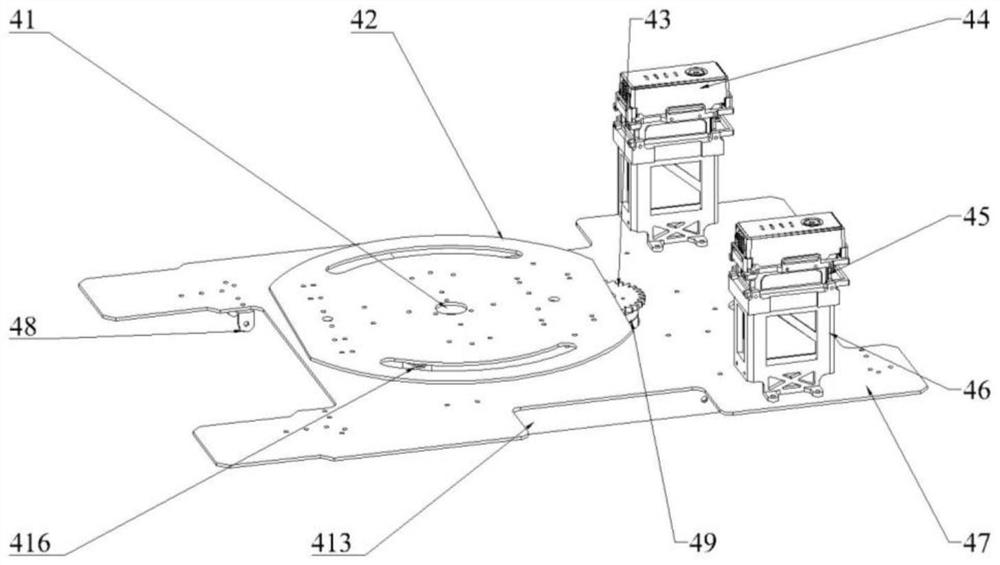

[0028] Such as figure 1 and figure 2 As shown, a tree planting robot in this embodiment includes a drilling device 1 for drilling holes on the ground to drill tree pits, a tree planting mechanical claw 2 for grabbing saplings and planting them, and for storing saplings. The sapling transfer device 3, the device main body 4, the driving device 5 that drives the robot to move and the soil covering device 6 that covers the saplings that are planted. Such as image 3 and Figure 4 As shown, the device main body 4 is used as the main body of the robot to provide interfaces for the assembly of other devices. The device main body 4 includes a car body base plate 47, and a battery rack 45 is fixedly arranged on both sides of the upper surface of the front end of the car body base plate 47, and the battery rack 45 top is fixedly connected. The battery holder 46 is used to install the battery 44 . The sapling transmission device 3 is set in the middle of the upper surface of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com