Internal partition type storage tank for premixed dry-mixed mortar

A dry powder mortar and storage tank technology, applied in tank trucks, packaging, large containers, etc., can solve problems such as moisture erosion, quality reduction, and inability to be directly put into use, and achieve the effect of reducing moisture resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

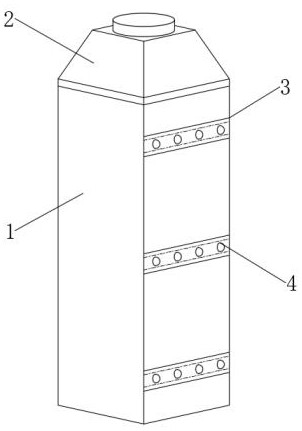

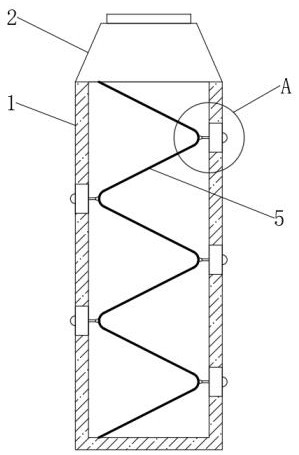

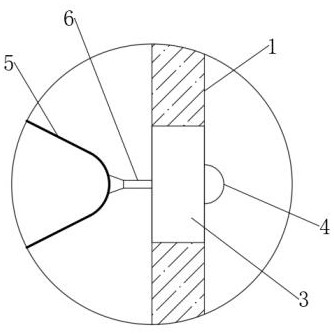

[0043] see Figure 1-4 , an inner compartment storage tank for ready-mixed dry powder mortar, including a tank body 1 and a tank cover 2, the inner end of the tank body 1 is inlaid with a matching inner wave barrier 5, and the inner wave barrier 5 is in a wave shape Extending down, the side wall of the tank body 1 is inlaid with a plurality of exhaust strips 3 corresponding to the troughs and peaks on the inner wave-baffle 5, and the outer end of the exhaust strip 3 is provided with a hemispherical groove, and the hemispherical groove is movable There is a matching plugging ball 4, and a plurality of elastic ropes are fixedly connected between the plugging ball 4 and the exhaust strip 3. The inner end of the exhaust strip 3 is provided with a migration groove connected with the hemispherical groove, and the migration groove slides A matching airtight side strip 6 is connected, and a sliding groove matching the airtight side strip 6 is opened on the inner wave-proof plate 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com