Shell-and-tube heat exchanger

A technology of shell-and-tube heat exchangers and shells, which is applied to the types of heat exchangers, shells of heat exchangers, indirect heat exchangers, etc., which can solve the time-consuming and laborious disassembly and assembly of heat exchangers and high maintenance costs of heat exchangers , low reliability of heat exchanger seals, etc., to achieve the effect of small quantity, easy disassembly and assembly, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

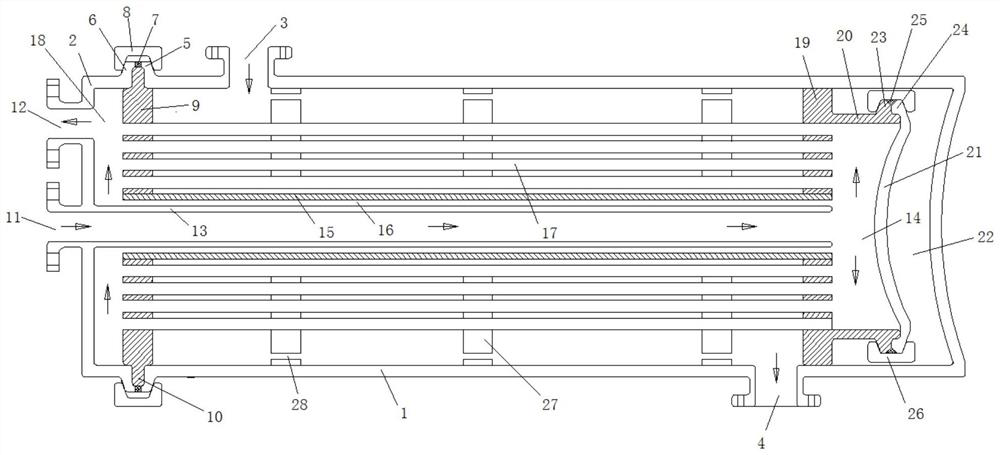

[0033] This embodiment provides a shell and tube heat exchanger, such as figure 1 As shown, it includes a shell 1 with one end open. The shell 1 is a cylindrical shell or a cubic shell. The shell 1 in this embodiment is a cylindrical shell.

[0034] The open end of the housing is provided with an end cover 2, and the end cover 2 and the housing 1 jointly form a closed heat exchange space.

[0035] The shell wall of the housing 1 is provided with a shell-side fluid inlet 3 and a shell-side fluid outlet 4. In this embodiment, the shell-side fluid inlet 3 is set at the end of the shell 1 close to the end cover 2, and the shell-side fluid outlet 4 is set at The other end of the shell 1, and the shell-side fluid inlet 3 is set on the top of the shell 1, and the shell-side fluid outlet 4 is set on the bottom of the shell 1. With this arrangement, it is convenient for the shell-side fluid to flow within the entire shell 1. The flow makes the heat exchange more sufficient.

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com