High-capacity battery structure

A large-capacity battery technology, applied to structural parts, secondary batteries, battery pack components, etc., can solve the problems of high production cost, complicated and cumbersome connection steps, and large consumables of the battery box, so as to save materials, reduce costs, The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

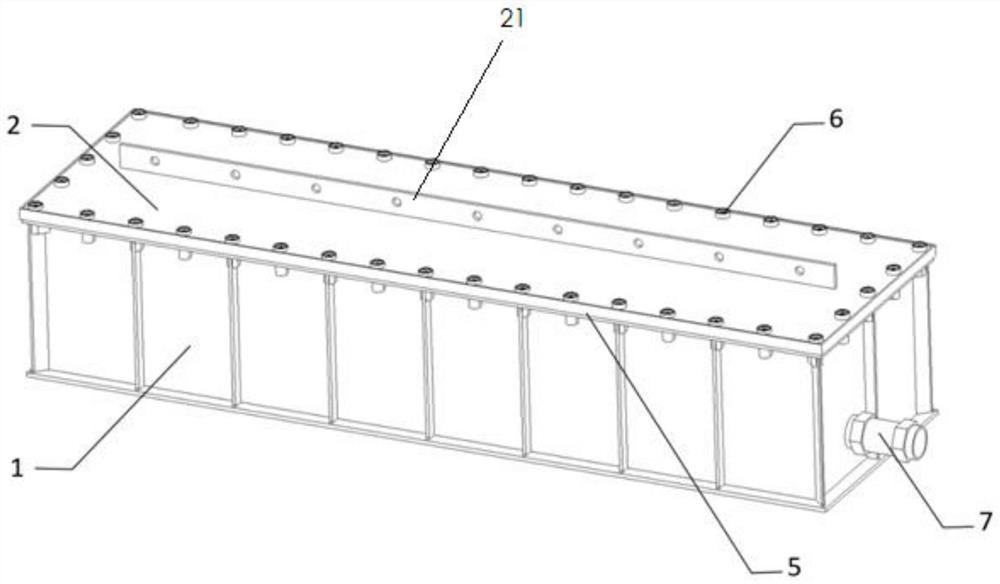

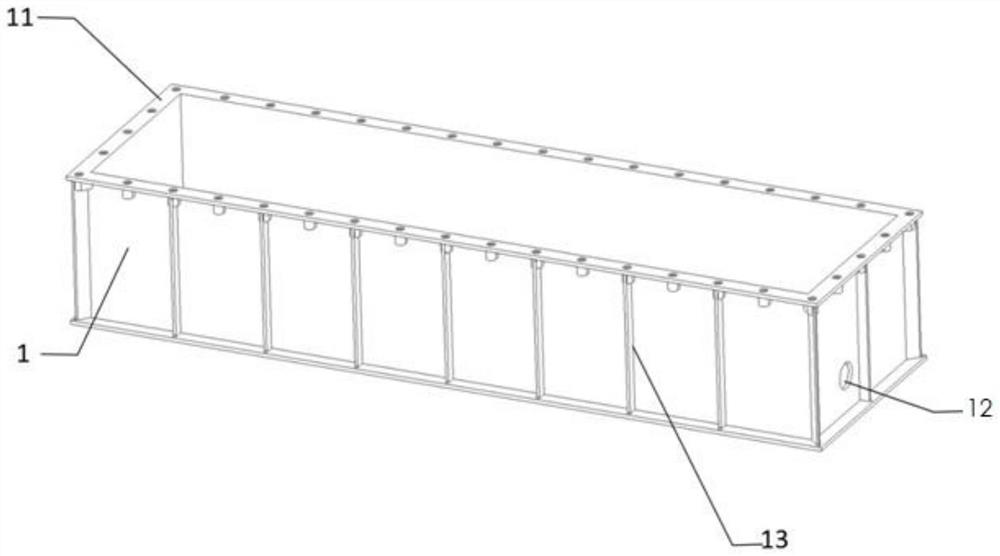

[0047] see figure 1 , a large-capacity battery structure in this embodiment, which includes a plurality of large-capacity battery units connected in series, the large-capacity battery unit includes a battery cylinder 1, and a positive electrode cover plate 2 is arranged at the opening of one side of the battery cylinder 1, and the The opening on the other side of the battery cylinder 1 is provided with a negative cover plate 3, the positive cover plate 2 is used as the positive pole of the large-capacity battery unit, and the negative cover 3 is used as the negative pole of the large-capacity battery unit; see Figure 5 , a positive electrode connection strip 21 is provided on the side of the positive electrode cover plate 2 away from the inner cavity of the battery cylinder 1, see Figure 6 , on the side of the negative cover plate 3 away from the inner cavity of the battery cylinder 1, a negative electrode connection bar 31 is provided. When multiple large-capacity units are...

Embodiment 2

[0051] This embodiment is a large-capacity battery structure. On the basis of Embodiment 1, the positive cover plate 2 is connected to the positive connecting bar 21 to form a structure with a T-shaped longitudinal section; the negative cover plate 3 is connected to the negative connecting bar 31 to form a longitudinal The cross-section is a T-shaped structure. When multiple large-capacity units are connected in series, the electrical connection between the positive cover plate 2 and the negative cover plate 3 is realized by overlapping the positive electrode connection strip 21 and the negative electrode connection strip 31, which facilitates the connection. The flow area between the positive cover plate 2 and the negative cover plate 3 is also increased.

[0052] see Figure 9 , Preferably, the positive connection bar 21 and the negative connection bar 31 of this embodiment are fixed by screws.

[0053] see figure 2 In this embodiment, a plurality of reinforcing ribs 13 a...

Embodiment 3

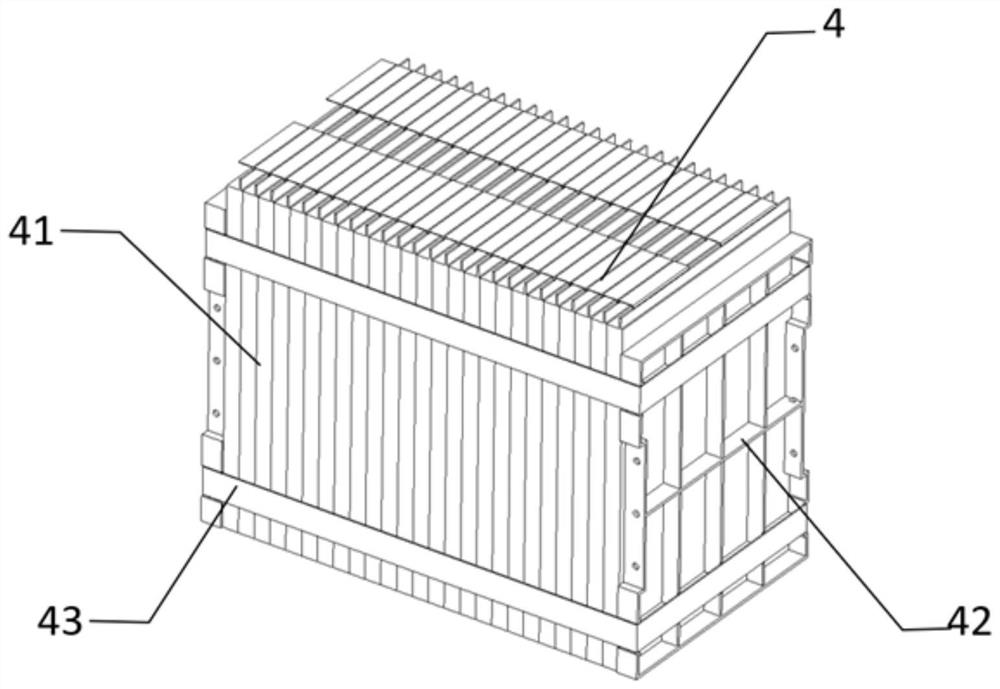

[0064] see image 3 , this embodiment is a large-capacity battery structure. On the basis of Embodiment 2, this embodiment also includes one or more battery modules 4, one or more battery modules 4 are placed in the battery cylinder 1, and the battery The positive electrode of the module 4 is electrically connected to the positive cover plate 2, and the negative electrode of the battery module 4 is electrically connected to the negative cover plate 3; The directions are set side by side. see Figure 4 , if there are multiple battery modules 4 , two adjacent battery modules 4 are fixedly connected by connecting pieces 44 .

[0065] It should be noted that the number of multiple battery modules 4 in this embodiment can be 2, 3, 4, 5, or even more, which is specifically set according to the capacity requirement of a single large-capacity battery unit.

[0066] see Figure 7 In this embodiment, the positive electrode of the battery module 4 is electrically connected to the pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com