Novel wastewater pumping device

A waste water pump, a new type of technology, applied to pump devices, components of pumping devices for elastic fluids, pumps, etc. And the effect of convenient maintenance, low maintenance cost and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] Example 1

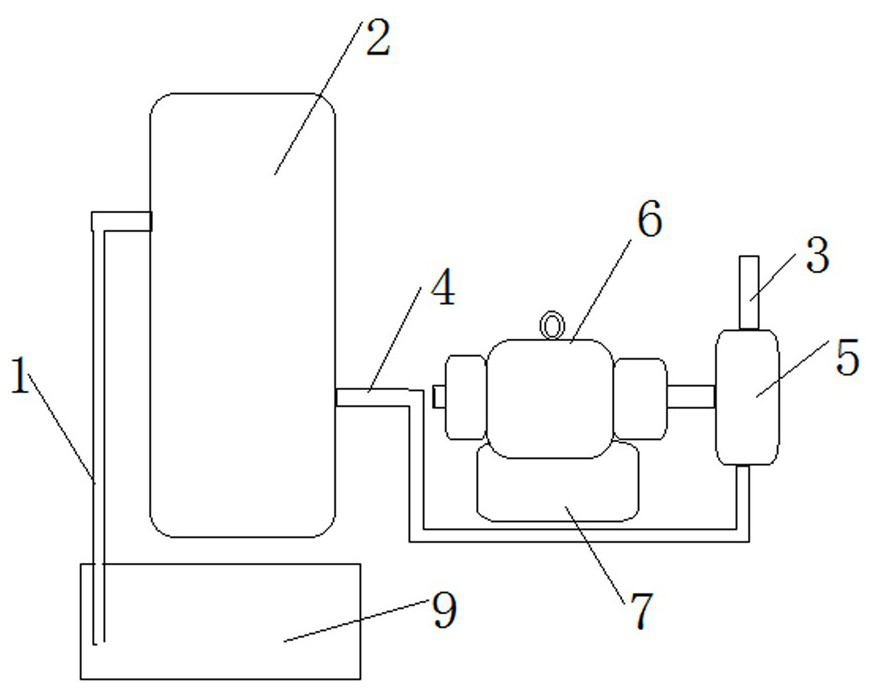

[0014] In a particular embodiment, the new wastewater pumping apparatus of the present invention, such as Figure 1 Shown, comprising a self-priming tank 2 and a pump host 6, the top of the self-priming tank 2 is connected to the wastewater pool 9 through the absorption pipe 1, the bottom of the self-priming tank 2 is connected to the pump turbine 5 through the pump input tube 4, the pump turbine 5 is connected to the output shaft of the pump host 6, the pump host 6 is fixed on the base 7; the pump turbine 5 is opened on the output pipe 3, the output pipe 3 is used to communicate the acid water station. In a specific embodiment, the absorbent pipe 1 is used to absorb wastewater into the self-priming tank 2, the pump turbine 5 is used to absorb wastewater from the self-priming tank 2 to the output pipe 3 and then to the acid water station for treatment. The pump host 6 is used to drive the rotation of the pump turbine 5. In a preferred embodiment, the pump turbin...

Example Embodiment

[0016] Example 2

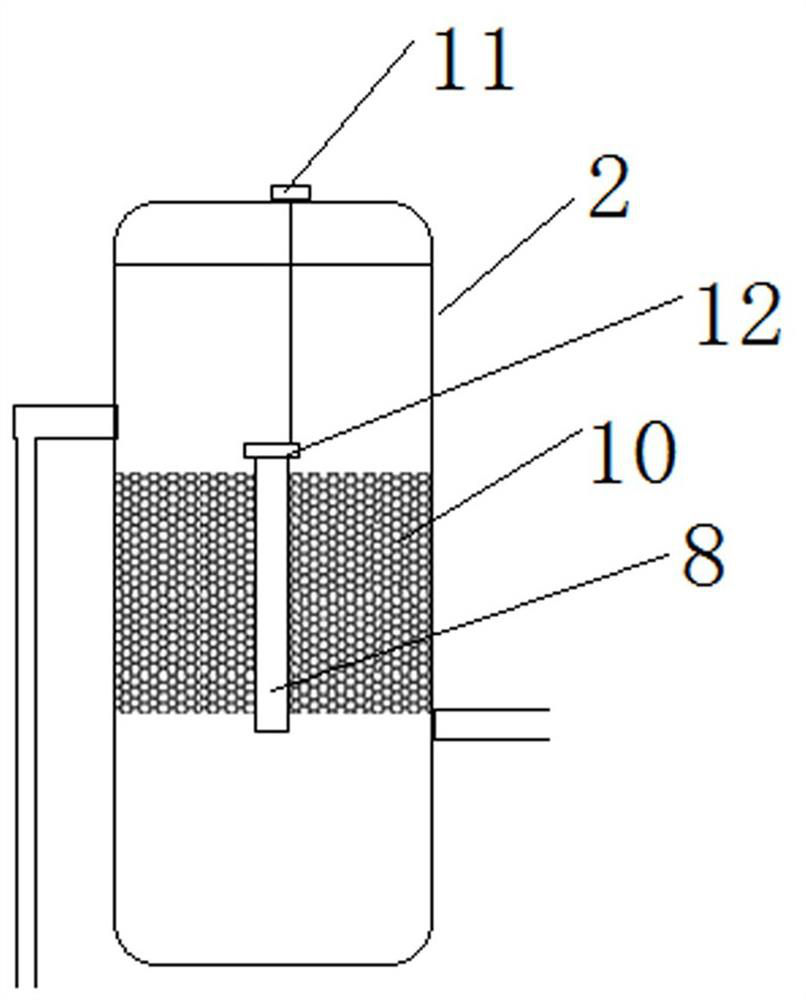

[0017] In a particular embodiment, the new wastewater pumping apparatus of the present invention, such as Figure 1 Shown, comprising a self-priming tank 2 and a pump host 6, the top of the self-priming tank 2 is connected to the wastewater pool 9 through the absorption pipe 1, the bottom of the self-priming tank 2 is connected to the pump turbine 5 through the pump input tube 4, the pump turbine 5 is connected to the output shaft of the pump host 6, the pump host 6 is fixed on the base 7; the pump turbine 5 is opened on the output pipe 3, the output pipe 3 is used to communicate the acid water station. In a specific embodiment, the absorbent pipe 1 is used to absorb wastewater into the self-priming tank 2, the pump turbine 5 is used to absorb wastewater from the self-priming tank 2 to the output pipe 3 and then to the acid water station for treatment. The pump host 6 is used to drive the rotation of the pump turbine 5. The self-priming tank 2 tanks are provided...

Example Embodiment

[0018] Example 3

[0019] In a particular embodiment, the new wastewater pumping apparatus of the present invention, such as Figure 1-2 Shown, comprising a self-priming tank 2 and a pump host 6, the top of the self-priming tank 2 is connected to the wastewater pool 9 through the absorption pipe 1, the bottom of the self-priming tank 2 is connected to the pump turbine 5 through the pump input tube 4, the pump turbine 5 is connected to the output shaft of the pump host 6, the pump host 6 is fixed on the base 7; the pump turbine 5 is opened on the output pipe 3, the output pipe 3 is used to communicate the acid water station. In a specific embodiment, the absorbent pipe 1 is used to absorb wastewater into the self-priming tank 2, the pump turbine 5 is used to absorb wastewater from the self-priming tank 2 to the output pipe 3 and then to the acid water station for treatment. The pump host 6 is used to drive the rotation of the pump turbine 5. The self-priming tank 2 tanks are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com