Automatic casing roll grading device

A technology of automatic grading and casing rolls, applied in sorting and other directions, can solve the problems of high labor intensity of staff, poor food safety awareness, and inconsistent sorting standards, achieving fast sorting speed, reducing labor intensity, The effect of standard unification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments, yet those who are familiar with the art should understand that the detailed description given here in conjunction with the accompanying drawings is for better explanation, and the structure of the present invention must exceed these limited embodiments, As for some equivalent replacement solutions or common means, this article will not describe them in detail, but they still belong to the protection scope of the present application.

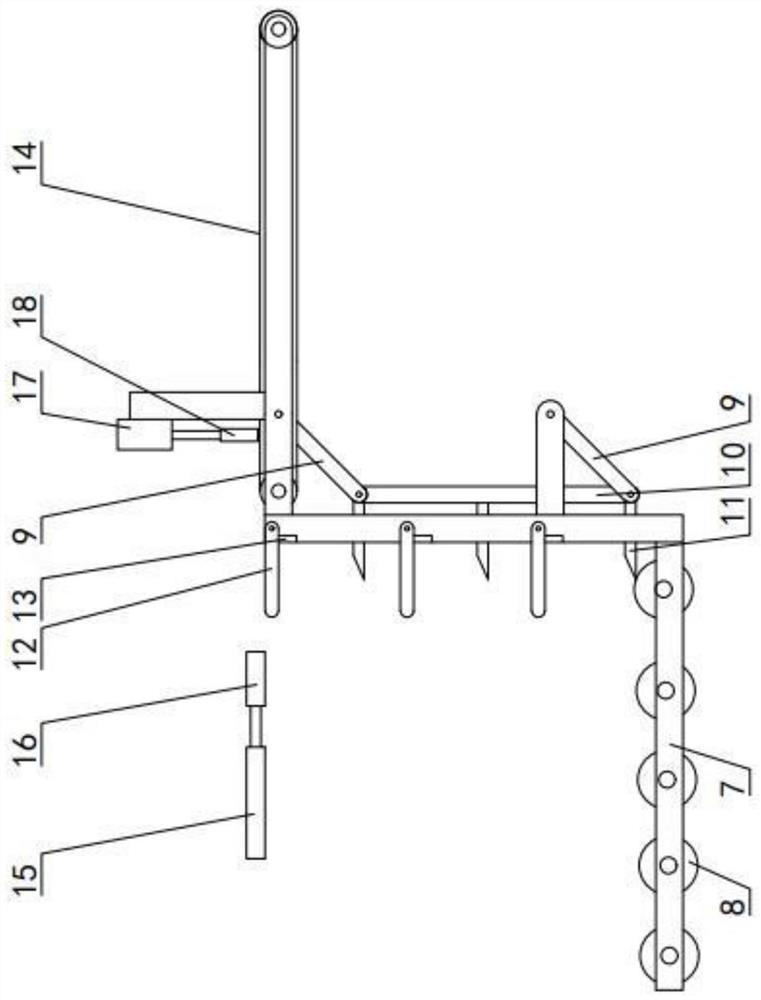

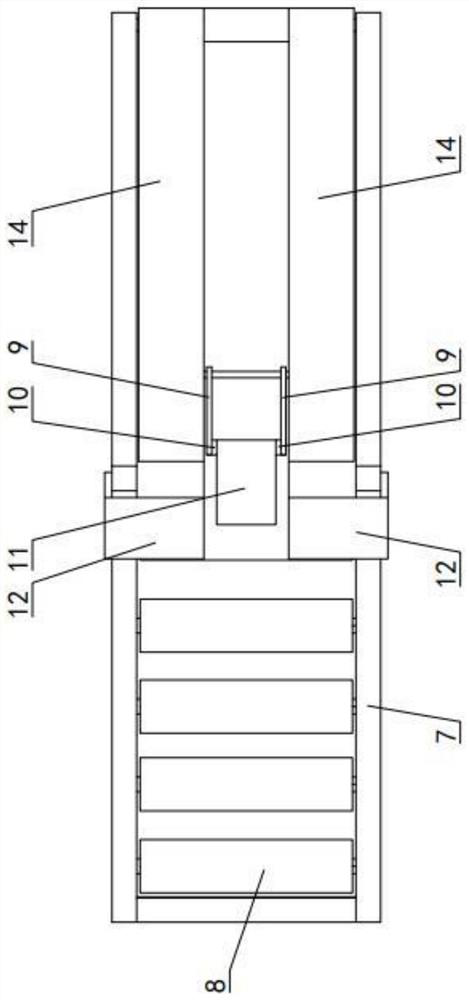

[0027] Figure 1-9 It is the best embodiment of the present invention, below in conjunction with attached Figure 1-9 The present invention will be further described.

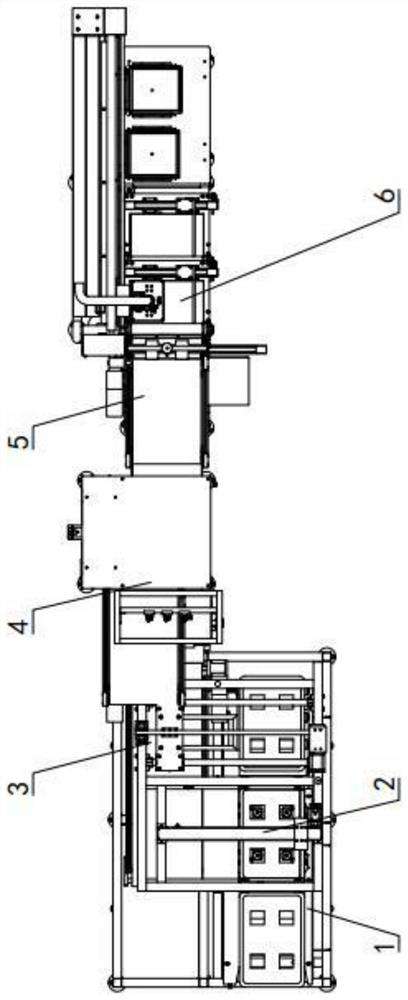

[0028] Automatic grading device for casing rolls, including a material frame conveying device, a casing roll pushing device, a casing roll detection device 4 and a casing roll sorting device 5, the casing roll detection device 4 and the casing roll pushing device are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com